Stainless Steel Flood Light

Company Profile

we specializes in the two major technical fields of LED lighting and explosion-proof electrical appliances in the explosion-proof electrical field of factories and mines. Based on this, we focus on the R & D, manufacturing and sales of three major types of products: LED industrial lighting (LED explosion-proof lamps, LED three-proof lamps), HID Industrial lighting, explosion-proof electrical equipment. Adhering to the development concept of scientific and technological innovation, the company vigorously promotes original technology, and has rich experience in the fields of LED explosion-proof lighting technology, HID industrial lighting, explosion-proof electrical technology, etc., and strives to exceed the domestic level of technology and product performance within 5 years, becoming the industry Technology pioneers and front runners. The company’s products are designed and manufactured strictly in accordance with GB3836 and IEC international standards, and implement strict quality control standards, aiming to provide customers with satisfactory service with the highest quality.

we specializes in the two major technical fields of LED lighting and explosion-proof electrical appliances in the explosion-proof electrical field of factories and mines. Based on this, we focus on the R & D, manufacturing and sales of three major types of products: LED industrial lighting (LED explosion-proof lamps, LED three-proof lamps), HID Industrial lighting, explosion-proof electrical equipment. Adhering to the development concept of scientific and technological innovation, the company vigorously promotes original technology, and has rich experience in the fields of LED explosion-proof lighting technology, HID industrial lighting, explosion-proof electrical technology, etc., and strives to exceed the domestic level of technology and product performance within 5 years, becoming the industry Technology pioneers and front runners. The company’s products are designed and manufactured strictly in accordance with GB3836 and IEC international standards, and implement strict quality control standards, aiming to provide customers with satisfactory service with the highest quality.

The company’s purpose: “Quality is the core, professional services, only the success of customers, we have success”, the establishment of a comprehensive and core marketing service system in the country, with high quality services to our customers and suppliers, mutual benefit Win-win success.

The company’s core values: “Sincerity must be, honesty, learning and innovation”, treat each other with sincerity, unity and cooperation, diligent study, technological innovation, and create a corporate brand!

The company insists on “safety, low carbon, energy saving, environmental protection” as the leading direction of research and development, and takes social responsibility as its own responsibility. Adhering to the “quality of the enterprise, the development of science and technology, and the strong culture of the enterprise”, the company strengthens its market competitiveness and lets the word spring The way from strength to excellence.

Our stainless steel floodlights

Floodlight

Floodlight, English name: Floodlight A floodlight is a point light source that can illuminate evenly in all directions. Its irradiation range can be adjusted arbitrarily, and it appears as a regular octahedron icon in the scene. Flood light is the most widely used light source in the production of renderings. Standard flood lights are used to illuminate the entire scene. Multiple flood lights can be applied to a scene. In order to produce a better effect, the shooting bulb is installed in a large reflecting umbrella for use as a high-brightness diffused light source. Although it is indispensable for indoor lighting, it is also one of the light sources with good lighting effects for general amateur indoor photography.

Floodlight, English name: Floodlight A floodlight is a point light source that can illuminate evenly in all directions. Its irradiation range can be adjusted arbitrarily, and it appears as a regular octahedron icon in the scene. Flood light is the most widely used light source in the production of renderings. Standard flood lights are used to illuminate the entire scene. Multiple flood lights can be applied to a scene. In order to produce a better effect, the shooting bulb is installed in a large reflecting umbrella for use as a high-brightness diffused light source. Although it is indispensable for indoor lighting, it is also one of the light sources with good lighting effects for general amateur indoor photography.

Floodlights are not spotlights, spotlights, or spotlights. Floodlights produce highly diffuse, non-directional light instead of sharply defined beams, resulting in soft and transparent shadows. When used for object lighting, the rate of illumination attenuation is much slower than when spotlights are used. Even some flood lights, which fade very slowly, look like a light source that does not produce shadows. Spotlights project a directional, well-defined beam of light to illuminate a specific area. As a replacement product of electric light source, flood light has been recognized by more and more people, and has been applied in many fields. Its main features are as follows:

Floodlights are not spotlights, spotlights, or spotlights. Floodlights produce highly diffuse, non-directional light instead of sharply defined beams, resulting in soft and transparent shadows. When used for object lighting, the rate of illumination attenuation is much slower than when spotlights are used. Even some flood lights, which fade very slowly, look like a light source that does not produce shadows. Spotlights project a directional, well-defined beam of light to illuminate a specific area. As a replacement product of electric light source, flood light has been recognized by more and more people, and has been applied in many fields. Its main features are as follows:

1.long life: general incandescent lamps, fluorescent lamps, energy-saving lamps, and other gas discharge lamps have filaments or electrodes, and the sputtering effect of the filament or electrode is an inevitable component that limits the life of the lamp. High frequency induction lamp requires no or less maintenance and has high reliability. The service life is up to 60,000 hours (calculated as 10 hours per day, the service life can reach more than 10 years). Compared with other lamps: 60 times that of incandescent lamps; 12 times that of energy-saving lamps; 12 times that of fluorescent lamps; 20 times that of high-pressure mercury lamps; the long life of floodlights greatly reduces maintenance troubles and replacement times , Saving material costs and labor costs, and can ensure long-term normal use. Since a floodlight has no electrodes, it emits light by combining the principle of electromagnetic induction with the principle of fluorescent discharge, so it does not have an inevitable component that limits its life. The service life depends only on the quality level of the electronic components, the circuit design and the manufacturing process of the bubble, and the service life can generally reach 60,000 to 100,000 hours.

1.long life: general incandescent lamps, fluorescent lamps, energy-saving lamps, and other gas discharge lamps have filaments or electrodes, and the sputtering effect of the filament or electrode is an inevitable component that limits the life of the lamp. High frequency induction lamp requires no or less maintenance and has high reliability. The service life is up to 60,000 hours (calculated as 10 hours per day, the service life can reach more than 10 years). Compared with other lamps: 60 times that of incandescent lamps; 12 times that of energy-saving lamps; 12 times that of fluorescent lamps; 20 times that of high-pressure mercury lamps; the long life of floodlights greatly reduces maintenance troubles and replacement times , Saving material costs and labor costs, and can ensure long-term normal use. Since a floodlight has no electrodes, it emits light by combining the principle of electromagnetic induction with the principle of fluorescent discharge, so it does not have an inevitable component that limits its life. The service life depends only on the quality level of the electronic components, the circuit design and the manufacturing process of the bubble, and the service life can generally reach 60,000 to 100,000 hours.

2.Energy saving: Compared with incandescent lamps, the energy saving is about 75%. The luminous flux of 85W floodlights is about the same as that of 500W incandescent lamps.

3.Environmental protection: It uses solid mercury agent, even if it is broken, it will not cause pollution to the environment. It has a recoverable rate of more than 99%, which is a true environmentally friendly green light source.

4.No strobe: Due to its high working frequency, it is regarded as “no strobe effect at all”, which will not cause eye fatigue and protect eye health.

5.good color rendering: color rendering index is greater than 80, light color is soft, showing the natural color of the illuminated object.

6. color temperature optional: from 2700K to 6500K, according to customer needs to choose, and can be made into colored light bulbs for garden decoration lighting.

6. color temperature optional: from 2700K to 6500K, according to customer needs to choose, and can be made into colored light bulbs for garden decoration lighting.

7.High visible light ratio: in the emitted light, the visible light ratio is more than 80%, and the visual effect is good.

8.No preheating required. It can be started and restarted immediately, and there will be no light decay in ordinary discharge lamps with electrodes after multiple switching.

9. excellent electrical performance: high power factor, low current harmonics, constant voltage power supply, output a constant luminous flux.

10.Installation adaptability: It can be installed in any position without restriction.

Application occasion

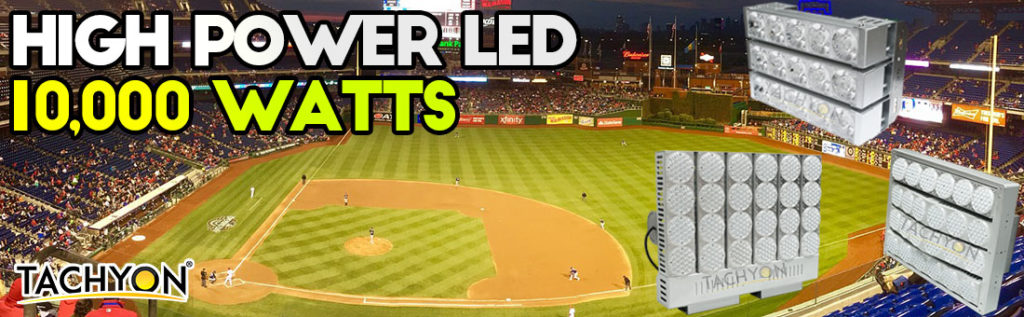

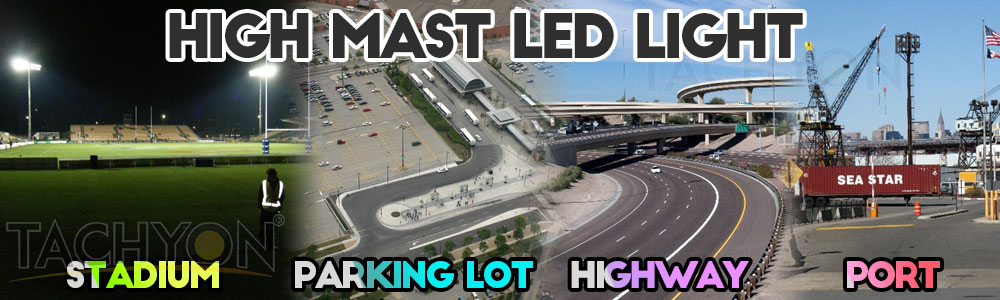

Main applications: large stadiums, billboards, highways, railway tunnels, bridges and culverts, squares, buildings, etc.

installation

Materials needed: LED fence light clip, waterproof transformer, sub-controller, the steps are as follows:

- Install guardrails, punch holes in the wall, and the spacing is generally within 3 cm according to actual requirements;

- Take good antistatic measures. For example, the workbench must be grounded. Workers wear appropriate electrostatic clothing and antistatic measures. Because different grades of LED floodlights have different qualities, they have different antistatic capabilities.

- Pay attention to the tightness during installation, the tightness is not good, and the diameter affects the service life of the LED flood light;

4.LED flood light wiring is best not more than 25 cm, the transformer power can be correspondingly longer, otherwise it will affect the brightness.

Note

- Use series LED forms as much as possible, because the voltage difference of LED flood light is special. The peak current of ordinary LEDs is maintained at 80 mA, and the reverse voltage is around 6V. When applying LEDs, pay attention to the peak voltage and current when designing the circuit under this limit.

- Use soldering iron with a voltage below 25 watts. The temperature of the electric soldering iron is controlled below 300 degrees Celsius. When exposed to high temperature, do not squeeze the epoxy part of the SMD LED or wipe it with a pointed hard object, because LED lamps are very fragile. Yes, it is easily damaged, and the welding time is under 3 seconds.

LED flood light is widely used, so the installation skills and precautions are very important. LED is a new light source. Under the correct installation method, it can ensure the stable and long-term normal operation of the LED flood light.

The material of the housing of the LED flood light is very important

The material of the housing of the LED flood light is very important

The common types of LED industrial lighting lamps used in industry mainly include the following product types: LED high bay lights, LED ceiling lights, LED flood lights and so on. The topic I want to talk about today is that the material of the housing of the LED industrial lamp is very important.

The housings of LED industrial lights on the market are divided into 2 types, and the material is made of PC or high-pressure cast aluminum. Daqi Optoelectronics LED industrial lamp is made of high-density aerospace aluminum material, and its surface is anodized and hardened, with high smoothness and good gloss. The material of the housing of the LED industrial lamp is very important. Of course, this type of aluminum is used for heat dissipation and good life. The only drawback is the high material cost and high selling price.

The housing material of LED industrial lights is very important. When you buy LED industrial lights, you must keep your eyes open and see what the housing material is.

Trends in the use of floodlights

Trends in the use of floodlights

Flood light, as a commonly used light source and light source for outdoor lighting, can be used in many occasions. For example, through analysis of specific scenes, you can find the suitable range of flood light use occasions. First, most of the outdoor light sources are public. Occasionally, ground lighting is the most commonly used place for floodlights except for street lights. Generally, parks are the best place. In many places where parks cannot be illuminated, floodlights are usually selected as the focus, because For the consumption of installing street lights everywhere, flood lights can save more energy. LED flood lights that have appeared in recent years have better lighting effects. At the same time, they can also make ordinary people feel the light at night, and also improve the shadyness of the park area Safety and avoid some potential risk factors.

Flood light needs in different occasions

At the same time, in the scene where floodlights are suitable, various types of celebrations are also the most common, especially concerts or festivals are the most common form. By placing floodlights in the venue area, the illumination range can be improved and marked. The corresponding venue range also plays a big role in managing and confirming the event venue, so the application of floodlights in this case is also suitable, especially to meet the night lighting problems during many festivals. Arrangement can achieve more expected effects. For example, the choice of venue layout and lighting color effects is a very good case. Therefore, the use of floodlights in modern environments is very practical and can also bring good results. Lighting effect, this is also the biggest reason why people demand this kind of lighting fixtures and the embodiment of specific needs.

At the same time, in the scene where floodlights are suitable, various types of celebrations are also the most common, especially concerts or festivals are the most common form. By placing floodlights in the venue area, the illumination range can be improved and marked. The corresponding venue range also plays a big role in managing and confirming the event venue, so the application of floodlights in this case is also suitable, especially to meet the night lighting problems during many festivals. Arrangement can achieve more expected effects. For example, the choice of venue layout and lighting color effects is a very good case. Therefore, the use of floodlights in modern environments is very practical and can also bring good results. Lighting effect, this is also the biggest reason why people demand this kind of lighting fixtures and the embodiment of specific needs.

About the shell material of LED flood light

What materials are made of common floodlight housings

What materials are made of common floodlight housings

According to market demand, different manufacturers use copper to make the housing of floodlights, but copper is more expensive, so it is made of aluminum, which is also good, and aluminum has a good heat dissipation effect. However, it cannot meet the protection of floodlights in all occasions. Of course, there is the worst plastic case for floodlights. Although some brand lights have a plastic shell on the outside, there is still aluminum inside for heat dissipation.

Aluminum alloy is the most commonly used material in the manufacture of lamps and lanterns. It is often heard that it is necessary to open the mold to make the lamp. After the opening, the aluminum alloy is pressed. There are zinc alloys: but the cost of aluminum alloys is relatively high. There are some lamp structures that do not have high material requirements and can be replaced with zinc alloys. Its quality is slightly heavier, but the cost is relatively cheaper. There are also steel plates: steel is also a very commonly used material in lamps and lanterns. It has a wide range of applications and is much cheaper than aluminum. There is also plastic: plastic is just a collective term. It includes many types, such as PCs, PMMA, etc., it is a class of high molecular polymers. Mirror aluminum mirror aluminum is unique in the lighting industry, and other products are rarely used.

The difference between aluminum alloy and stainless steel

The difference between aluminum alloy and stainless steel

- Price: stainless steel is expensive, aluminum alloy is cheap

- In terms of hardness: stainless steel has low density, but high strength, close to steel, and good plasticity. Stainless steel is a nickel-chromium alloy with higher hardness than aluminum alloy.

3. high temperature resistance: stainless steel can withstand high temperature, melting point is 1200-1500 degrees, aluminum alloy can not withstand too high temperature, melting point is 500-800 degrees.

- Surface treatment: stainless steel surface treatment includes surface brightening treatment, surface whitening treatment, and surface coloring treatment. Aluminum alloy treatment includes electrophoresis, spray coating, anodizing, etc.

- Industrial application: stainless steel has heat resistance, oxidation resistance, good formability and good weldability, and can be used as an ultra-high-strength material in the nuclear industry, aviation and aerospace industries; aluminum alloys are used for processing needs Good formability but does not require high strength parts such as chemical products, food industry equipment and storage containers, printing plates, nameplates, reflective appliances, etc.

Many aluminum alloy products and stainless steel products are used in our daily life, such as pots and basins. In simple terms, aluminum products are light in weight, soft in material, and dark in color. Stainless steel products are heavy in quality, hard in material and bright in color.

Stainless Steel

Stainless steel (Stainless Steel) is an abbreviation for stainless acid-resistant steel. Steels that are resistant to weakly corrosive media such as air, steam, and water, or stainless steel are called stainless steel. The type of steel that is corroded is called acid-resistant steel.

Stainless steel (Stainless Steel) is an abbreviation for stainless acid-resistant steel. Steels that are resistant to weakly corrosive media such as air, steam, and water, or stainless steel are called stainless steel. The type of steel that is corroded is called acid-resistant steel.

Due to the difference in chemical composition between the two, their corrosion resistance is different. Ordinary stainless steel is generally not resistant to chemical media corrosion, while acid-resistant steel is generally stainless. The term “stainless steel” refers not only to a single type of stainless steel, but to more than a hundred industrial stainless steels, each of which has been developed to have good performance in its specific application. The key to success is to first figure out the purpose and then determine the right steel grade. There are usually only six types of steel related to the application of building construction. They all contain 17 to 22% chromium, and the better steels also contain nickel. The addition of molybdenum can further improve the atmospheric corrosivity, especially the corrosion resistance of chloride-containing atmospheres.

Stainless steel refers to steel that is resistant to corrosion by weakly corrosive media such as air, steam, and water, and chemically corrosive media such as acid, alkali, and salt. In practical applications, steel that is resistant to weakly corrosive media is often referred to as stainless steel, and steel that is resistant to chemical media is referred to as acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to corrosion by chemical media, while the latter are generally stainless. The corrosion resistance of stainless steel depends on the alloying elements contained in the steel.

Stainless steel refers to steel that is resistant to corrosion by weakly corrosive media such as air, steam, and water, and chemically corrosive media such as acid, alkali, and salt. In practical applications, steel that is resistant to weakly corrosive media is often referred to as stainless steel, and steel that is resistant to chemical media is referred to as acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to corrosion by chemical media, while the latter are generally stainless. The corrosion resistance of stainless steel depends on the alloying elements contained in the steel.

Main features of stainless steel

Weldability

Different products have different requirements for welding performance. A type of tableware generally does not require welding performance, and even includes some pot enterprises. But most products need good welding performance of raw materials, such as second-class tableware, insulation cups, steel pipes, water heaters, water dispensers, etc.

Corrosion resistance

Most stainless steel products require good corrosion resistance, such as Class I or II tableware, kitchenware, water heaters, water dispensers, etc. Some foreign merchants also perform corrosion resistance tests on the products: use NACL solution to heat to boiling, and then pour Remove the solution, wash and dry, and weigh the weight loss to determine the degree of corrosion (Note: When the product is polished, the surface of the test will cause rust spots due to the presence of Fe in the abrasive cloth or sandpaper)

Polishing performance

In today’s society, stainless steel products are generally polished during production. Only a few products, such as water heaters and water dispenser liners, do not need polishing. Therefore, it is required that the polishing performance of the raw material is good. The factors that affect the polishing performance are the following:

① Surface defects of raw materials. Such as scratches, pitting, over pickling and so on.

② the problem of raw material. If the hardness is too low, it will not be easy to be polished when polishing (BQ property is not good), and the hardness is too low, and the orange peel phenomenon will appear on the surface during deep drawing, which will affect the BQ property. BQ with high hardness is relatively good.

③ After deep drawing, small black spots and RIDGING will appear on the surface of the area with a large amount of deformation, which will affect the BQ performance.

Heat resistance

Heat resistance means that stainless steel can still maintain its excellent physical and mechanical properties at high temperatures.

Effect of carbon: Carbon is strongly formed and stable in austenitic stainless steel. Element that sets austenite and enlarges the austenite region. The ability of carbon to form austenite is about 30 times that of nickel. Carbon is a gap element. The strength of austenitic stainless steel can be significantly improved by solid solution strengthening. Carbon can also improve the stress and corrosion resistance of austenitic stainless steel in highly concentrated chlorides (such as 42% MgCl2 boiling solution).

However, in austenitic stainless steel, carbon is often regarded as a harmful element. This is mainly due to the conditions under which the stainless steel is used for corrosion resistance (such as welding or heating at 450 ~ 850 ° C). Chromium forms a high chromium Cr23C6 type carbon compound, which results in the depletion of local chromium, which reduces the corrosion resistance of the steel, especially the resistance to intergranular corrosion. therefore. Most of the newly developed chromium-nickel austenitic stainless steels since the 1960s have ultra-low carbon types with a carbon content of less than 0.03% or 0.02%. It can be known that as the carbon content decreases, the intergranular corrosion sensitivity of steel decreases. 0.02% has the most obvious effect, and some experiments have also pointed out that carbon will also increase the pitting corrosion tendency of chromium austenitic stainless steel. Due to the harmful effects of carbon, not only the carbon content should be controlled as low as possible during the austenitic stainless steel smelting process, but also the surface of the stainless steel should be prevented from increasing carbon during the subsequent hot, cold working and heat treatment, and chromium carbides Precipitation.

Corrosion resistance

When the amount of chromium atoms in the steel is not less than 12.5%, the electrode potential of the steel can be abruptly changed from a negative potential to a positive electrode potential. Prevents electrochemical corrosion.

The Features of Stainless Steel Flood Light

* Stainless steel shell with strong anti-corrosion ability

* High-energy impact-resistant toughened glass transparent cover

* Orange diffuse reflection plate, high reflection efficiency, uniform light, effectively reduce glare

* Fastened with buckle for easy maintenance

* High power factor> 0.90

* The elevation angle of the lamp body can be adjusted between 45-90 degrees

* Light fixtures are light, beautiful and generous

HRT81-L1000 Explosion-proof and anti-corrosion flood light * Cable wiring.

Summary:

Due to the widespread use of LED floodlights, large-power floodlights are used in more and more places, such as large stadiums, industrial and mining industries, docks, various outdoor places, for various harsh natural environmental requirements, so for LEDs The choice of the material of the light pole and the housing of the floodlight is very important, so it combines the advantages of stainless steel, high temperature resistance, corrosion resistance, and color unchanged. Therefore, we specialize in the production of stainless steel floodlights and provide high-quality LED lights for large-scale occasions. This can ensure the stable and long-term normal work of LED floodlights. Beautiful and energy saving.