LED lights are continuously improved to achieve better use, greater versatility and more efficient power usage. Compared with traditional incandescent lamps, different types of LED lights are very popular, mainly because their service life can be extended by about 25 times, but the energy consumption is less.

LED lights come in a variety of models. Start comparing COB vs SMD LED Lights, or before you look at the difference between LED light COB and SMD.You can choose between SMD vs COB types, for example, depending on your needs for energy efficiency and versatility. The COB vs SMD LED Lights differ in terms of their features and semiconductors.

1.What is COB?

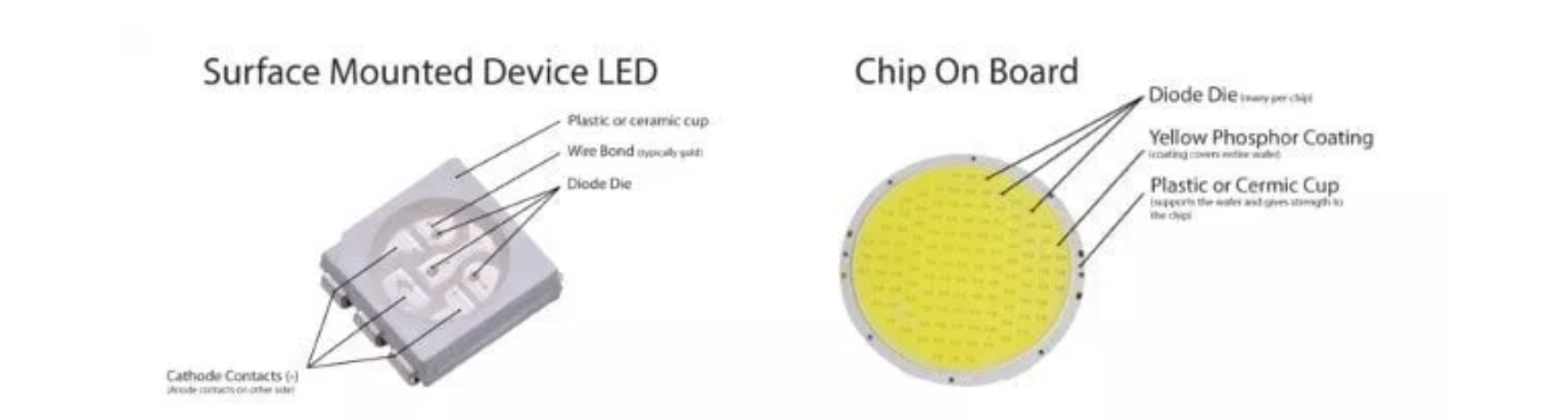

One of the most recent developments in LED, COB or “Chip on Board” technology is a step forward more efficient energy use.Like the SMD, COB chips also have multiple diodes on the same surface. But the difference between LED light COB and SMD is that COB LEDs have more diodes.

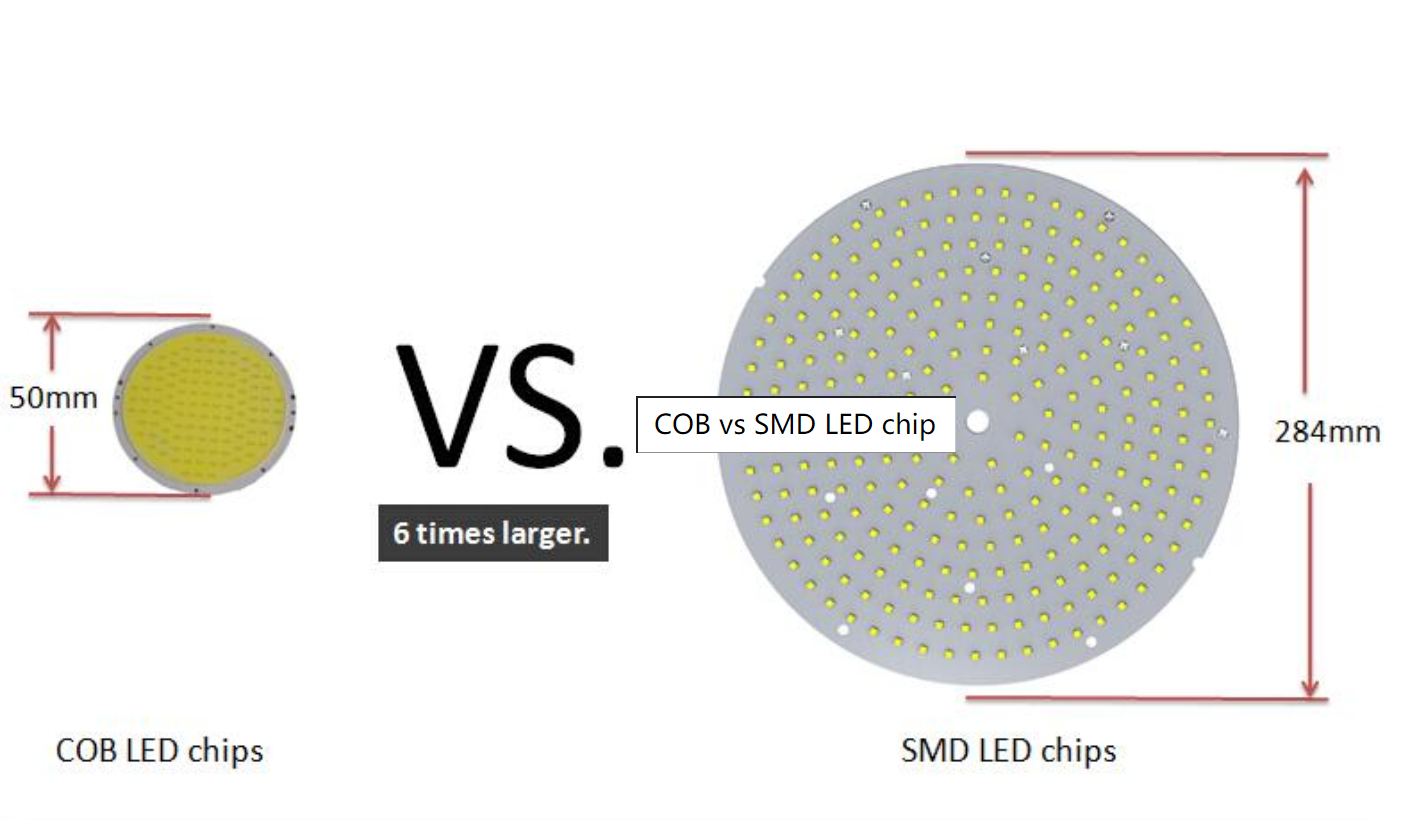

COB chips typically have 9 or more diodes. COB chips also only have 1 circuit and 2 contacts, regardless of the number of the diodes. This simple circuit design is the reason for the panel-like appearance of COB LED light (SMD light, on the other hand, appears like a collection of smaller lights).

COB is known for better lumen-per-watt ratios and heat efficiency. This has a lot to do with the design of COB LEDs, and the cooling ceramic substrate of the chips. COB chips can produce a large amount of lumens with less energy. You can find it in all kinds of bulbs and applications, such as the flash of your mobile phone or point-and-shoot camera. Its range is higher with a minimum of 80 lumens per watt.

2.What is SMD?

SMD refers to the term “Surface Mounted Device” LEDs, which are the utmost shared LEDs in the market. The LED chip is eternally fused to a printed circuit board (PCB), and it is especially popular because of its versatility. The PCB is built on a rectangular-shaped, flat object, which is what we usually see as SMD. If you look into SMD LED closely, you can see a small black point right in the center of the SMD; that is the LED chip. You can find it in light bulbs and filament lights and even in the notification light on your mobile phone.

The SMD LED chips come in a variety of sizes. SMD LED can accommodate chips with complicated designs, like the SMD 5050, which is 5mm wide. The SMD 3528, on the other hand, are 3.5mm wide. The SMD chips are small, almost close to the design of the flat, square computer chip.

One of the distinct features of SMD LED chips is the number of contacts and diodes they have. SMD LED chips can have more than just two contacts (which makes it different from the classic DIP LED). There can be up to 3 diodes on a single chip, with each diode having an individual circuit. Each circuit would have one cathode and one anode, leading to 2, 4 or 6 contacts in a chip.

SMD chips have played a significant role in the progress for the LED industry because of the ability to put three diodes on the same chip. When a chip contains a red, green, and blue diode, it can create any color you want by adjusting the level of output from each diode on the chip. As they are very bright and can change colors, it can be used extensively for LED strip lights and light bulbs.

The chip is protected with phosphor powder and looks like yellow or orange. The yellow one usually emits daylight white (6000-6500K), and the orange one generally emits warm white light (2700-3500K). The SMD chip is also very bright. They can produce 50 to 100 lumens per watt.

3.Advantages of COB and SMD:

COB:

a. Low production failure rates. .

b. Generate a higher amount of lumens with less energy.

c. Better thermal conduction. Hence, chips distances are shortened, and space is saved.

d. The circuit can be designed according to customer requirements, and the heat dissipation is more practical, which can effectively avoid the disadvantages like spotlight and glare of the discrete light source device combination.

SMD:

a. It has high reliability and strong anti-vibration capability.

b. Low solder joint defect rate and improve production efficiency.

c. The SMD is more flexible, and the display of its chips is decided according to the printed circuit board layout, and it can be altered to meet different engineering solutions.

d. SMD light source has a bigger illumination angle of up to 120 & Phi; 160 degrees, small size and light weight of electronic products, high assembly density and the size and weight of the cover components are only about 1/10 of that of conventional plug-in components.

4.Differences between SMD and COB LED lights:

COB:

a. COB is known for better lumen per watt ratios and heat efficiency. COB chips can produce a higher amount of lumens with less energy with a minimum of 80 lumens per watt. You can find it in all types of bulbs and applications, like the flash of your mobile phone or point-and-shoot camera.

b. COB chips normally have 9 or more diodes. Moreover, COB chips also have 1 circuit and two contacts, regardless of the number of diodes. This simple circuit design is the reason for the panel-like presence of COB LED light where on the other hand, SMD light, appears like a group of smaller lights.

c. Though, COB LED lights cannot be used to generate color-changing bulbs or lights because there are only two contacts and 1 circuit. Multiple channels adjustments are required to create the color changing effect. Hence, COB LED lights are efficient in single-color applications but not in versatile technology.

SMD:

a. SMD chips are known for their brightness, and it can produce 50 to 100 lumens per watt.

b. SMD LED chips can have up to 3 diodes on a single chip, with each diode having an individual circuit. Each circuit has one cathode and one anode, leading to 2, 4 or 6 contacts in a chip.

c. This alignment is the reason why SMD chips are more versatile comparing to COB. The chip can contain a red, green, and blue diode. By using these three diodes, you can create any color simply by adjusting the output level.

5.Conclusion

All in all, I would like to say that SMD and COB have a wide range of applications, but SMD is relatively customized and can meet the needs of various lamps. However, you can choose between SMD or COB types based on the need for energy efficiency and versatility.