The Effect of Temperature on Phosphor

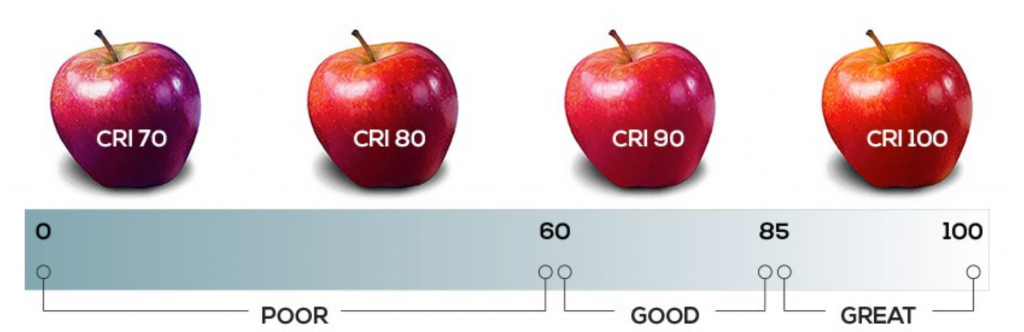

With the continuous development of LED technology, it is possible to use LED as a lighting source. As the light source has strict requirements on the color rendering index CRI in lighting fixtures, the current white LED technology is not mature in terms of color rendering, making it a The main obstacle restricting LED as a lighting source.

White light is a composite light, and the light of various colors contained in the white light can be easily decomposed through a prism. The LED is a light source with a more comprehensive color spectrum. This wide color gamut has laid a theoretical foundation for the high color rendering of LED lighting products.

Light is a material with wave-particle duality. This material contains the characteristics of waves and the characteristics of particles, which makes it have strong composite characteristics. Therefore, in terms of the nature of light and the characteristics of LEDs, It is possible for LEDs to become high-quality lighting sources.

The current white light LED technology mainly adopts the manufacturing process of blue chip coated with phosphor powder. This technology was developed by Nichia, and to a certain extent follows the light-emitting principle of fluorescent tubes. This technology is due to the lack of red and green light components. In order to make up for this defect, phosphor technology has become the main direction of the industry.

The blue chip is coated with phosphor to make white light technology. This technology can produce white light with better effects in principle. However, due to the weak adaptability to the environment during use, the difference between the theory and the actual product is caused. The difference is largely due to the influence of LED thermal accumulated temperature on phosphors.

We all have this experience. With the passage of working time, the heat generation and heat dissipation of high-power white LEDs gradually reach a state of equilibrium. The higher the temperature of this equilibrium state, the greater the impact on white LEDs using the same type of phosphor.

As the LED temperature continues to rise, the phosphor activity will be greatly reduced (Fahrenheit/Celsius conversion formula is: Celsius = 5/9* (Fahrenheit -32), the phosphor activity is better at 100 degrees Fahrenheit, but at The phosphor’s activity is basically lost at around 250 degrees Fahrenheit (120 degrees Celsius).

While temperature affects the activity of the phosphor, it also has a certain impact on the wavelength of the light wave excited by the phosphor.

The Effect of Phosphor Activity on CRI

As the temperature of the LED rises, the phosphor activity is gradually deactivated, and the wavelength of the light emitted by the phosphor also shifts. This shift is a red shift, that is, the emission wavelength of the phosphor shifts toward the red wavelength. ; This phenomenon seems to indicate that as the temperature rises, the color rendering of the white LED should be better, but in fact it is reduced. It seems to be a contradiction? The essence of this phenomenon is that the offset of the phosphor to the red wavelength is less than the deactivation amount of the phosphor, that is, the red light excited by the phosphor at high temperature is not enough to make up for the red light lost by the mixing, so it is expressed as As the temperature rises, the color rendering index of the LED still drops, which is consistent with the decline in the color rendering index of the white LED as the temperature rises.

From the above analysis, it can be concluded that the first method to improve the color rendering index of phosphor white LED is to reduce the temperature of the LED, and the second is to improve the ability of the phosphor to adapt to high temperatures. The third is to use color compensation technology, using red or amber LED to compensate for the color rendering index.

In terms of reducing the temperature of LEDs, the most effective means is to design LED packaging methods with higher heat dissipation performance. This is one of the directions where my country’s LED industry can make significant progress in LED intellectual property rights in the near future, because LEDs are a kind of low voltage For electronic products, electrical safety requirements are relatively loose, so there are more thermally conductive substrate materials that can be used, and our industry currently has less research on this, causing frequent violations of foreign intellectual property disputes.

Improving the stability of phosphors is the mainstream of white LED technology. In this regard, my country’s current technical strength is relatively weak, and breakthroughs cannot be made in the short term. It is difficult for most Chinese companies to seek breakthroughs in this area.

Color compensation technology is a technical means to compensate for the decrease of LED color rendering index due to lack of color. This technical means is feasible in principle, but in practical applications, it faces strict restrictions on the technical means of mixing light conditions. , So the actual application value is not high.

White light conforms to the light mixing theory based on red, green and blue 3:6:1. This theory is based on our looking at light-emitting objects. This light mixing technology can be successfully applied to the white balance technology of LED displays, but The application of this kind of light mixing scheme in lighting schemes does not have much reference. This is because the human eye has an average characteristic and a habitual characteristic for visible light, and these two characteristics are also unknowingly. An important cause of damage to eyesight.

The essence of lighting is that the light shines on the object, and the object enters the human eye through reflection. This forms the lighting process. Because the object absorbs different wavelengths of light differently, the pure red, green and blue three-color LEDs pass The white light produced by the 3:6:1 mixing technology has certain color defects in itself, and it irradiates the surface of the object. Because the red, green, and blue are absorbed by the surface of the object and the reflection effect is different, the CRI is reduced. Therefore, white light products produced by using three-primary color mixing technology should first use technical means to mix the light on the surface of the component or inside the product to make it emit white light, instead of emitting three different lights to mix light on the surface of the illuminated object. This causes the CRI to decrease.

Red, green and blue LED color mixing technology is a relatively mature white lighting technology. This technology has a long light mixing distance due to the large distance between different LEDs. Adding a light mixing cover in front of the LED, although it solves the problem of light mixing However, the light loss is another obstacle, which is an obstacle to the development of light and thin lighting fixtures. Moreover, when people directly look at the lighting fixture, it is not uniform white light; these two factors directly restrict the development of this technology.

The research on the three-primary color LED light mixing technology is based on solving these two problems. The study found that as the distance between the LED chips decreases, the light mixing distance decreases exponentially, and the light mixing effect increases exponentially with the increase in the concentration of the dispersant coated on the surface of the three primary colors. Finding an optimal balance point between the reduction of the three-primary color LED chip spacing and the increase of the concentration of the three-color agent is the best solution to the three-primary color mixing. This solution makes it possible to use the three-primary white LED as a lighting source.

Effect of Dispersant on Light

As the concentration of dispersant increases, the light loss gradually increases. However, in the process of experimental research, we found that the colloid light loss used in the current packaging technology is about 5%, while the amount of light loss encapsulated by the colloid doped with dispersant The light loss of LED is about 12%, but it achieves a better light mixing effect, which is 7% more light loss than the original transparent colloid light loss, and achieves a more perfect light mixing effect. From the actual product In terms of application value, this is worthwhile.

The object of our research is a compact SMD three-in-one package, a flat lensless type. This package requires that the distance between the internal red, green and blue LED chips is less than 1mm and is a low-power chip.

In terms of high power, the white light LED produced by the phosphor coating technology and the LED produced by the three-color chip dispersion agent light mixing technology have roughly the same amount of light loss, while the three-color chip dispersion agent light mixing technology is more Simple and effective, we should go further in this technology.

There are many ways to solve the color rendering of LEDs from the practical technology of LEDs. This article focuses on the practical significance of CRI. At present, although white LEDs produced by blue chip coating technology occupy the mainstream of the market, as the research deepens Development, with the continuous progress of technology, with the continuous improvement of packaging technology, three primary color white LED technology will make great progress.