Can I Replace Metal Halide with LED?

We can replace the 400-watt metal halide lamp with a 150-watt LED lamp. We can also replace the 100-watt metal halide with a 40-watt LED lamp. Replacing the lighting in homes, factories, parking lots, stadiums, gas stations and other places with LED lights will reduce annual energy use (kWh) costs by at least 60%.

Nowadays, the lighting of stadiums, industrial plants, large retail stores, manufacturing facilities and warehouses are usually equipped with HID lamps, and metal halide lamps and high-pressure sodium lamps are often used. Metal halide shed lights generally have high power, large illumination angles, and wide coverage, which can provide them with the required lumen output and conventional lighting distribution.

The metal halide lamp needs to be connected to the ballast, which can provide strong, white and bright light. The life of the lamp is up to 20,000 hours. The halide in the quartz tube improves color reproduction, which gives the metal halide lamp higher quality lighting, which is usually required in high bay lighting. This is not possible with mercury vapor or high-pressure sodium lamps.

Metal halide lamps are still used in many occasions, but the emergence of LED canopy light with higher luminous efficiency output provides people with more and better choices. Especially used in school gymnasiums, gas stations, parking lots, tunnels, warehouses and other places. The use of LED lights greatly saves electricity costs.

There are more and more LED options for replacing high-power metal halide lamps in the market. The LED replacement is to disconnect the ballast, that is, rewiring to bypass the ballast from the circuit, and directly connect the driving power of the LED lamp to the grid, so that the LED lamp can be lit.

Although the advantages of LED lamps used to replace metal halide lamps may not be as significant as those used to replace halogen lamps and incandescent lamps, they are still highly recommended because LED lamps are more energy-efficient and environmentally friendly in the long run.

LED consumes less energy, has longer life span, and flexible control method

Generally, the lifespan of incandescent lamps is only 1000 hours, while the lifespan of halogen lamps is 2000 hours. Compared with this, LED lamps have a very obvious advantage because they have a service life of 35,000 to 50,000 hours. For metal halides, it is not so obvious.

Generally, the rated life of metal halide lamps used in canopies is not very long, only about 20,000 hours, but it is still less than half of the life of LED lamps. Although the initial cost of LED lamps is higher than the cost of halogen lamps, we must comprehensively consider (for example, during the next 3 years of use) the electricity costs incurred.

Another important point is that the reason why we decided to replace metal halide lamps with LED lamps is because the labor cost of LED lamps during use is much less than that of metal halide lamps. The labor required to replace metal halide bulbs is twice that of LEDs. This labor cost alone has exceeded the cost difference of the lamp itself.

In addition to the lifespan of the lamp, other factors are also important. The energy savings can be huge. We can replace the 400-watt metal halide lamp with a 150-watt LED light. A 40W LED light can replace a 100W metal halide lamp. Regardless of whether it is a home, school, factory, sports field or parking lot, the use of LED lights will reduce the cost of annual energy use (kWh) by at least 60%. The most intuitive result is a significant reduction in electricity demand (kW) costs. The number of lamps to be replaced, working time and electricity costs ($/kWh) are the three key factors that affect the cost savings after replacement.

In addition to long service life and low energy consumption, and overcoming the specific shortcomings of metal halide light, LED technology has other potential benefits.

Metal halides require 2 to 5 minutes of start-up warm-up time before they can achieve full light output. In addition, if the power supply is interrupted (even if it is temporarily interrupted), the traditional probe activated metal halide system requires 5 to 10 minutes of cooling time to restart the lamp, and then requires an additional 10 to 15 minutes of heating time before reaching full brightness .

The hot start time of the pulse start system is reduced to about 220 seconds. However, any accidental interruption of lighting will affect the normal operation of the lamp for a period of time. LED is a brand-new lighting technology. Its instant-on feature ensures that no matter what the temperature of the space is, as long as the switch is turned on, the light will light up instantly, with a response time of only 0.15 milliseconds.

Compared with metal halide light, LED light is also a light source that is easier and more diversified to control. Because it is turned on immediately, in some occasions, the lights in it will be controlled by sensors to ensure that the lights are turned on only when lighting is needed in that occasion.

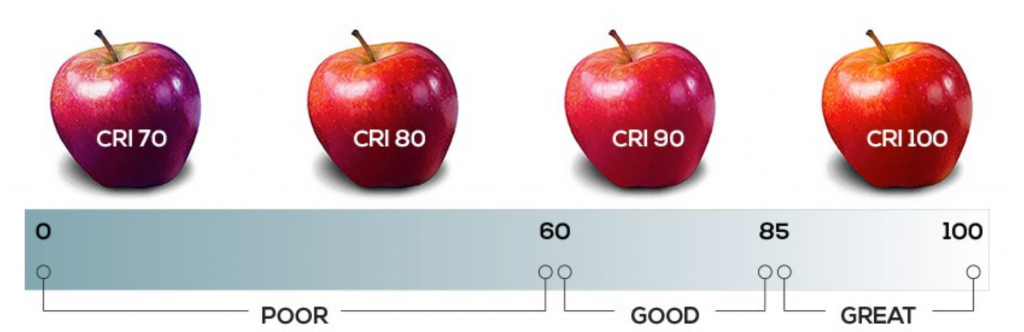

Compared with the replaced metal halide lamps, LED lights have higher lighting quality, better color rendering, better illuminance uniformity, flexible and diverse CCT and customized light-emitting angles.

Precautions when replacing MH with LED

Safety is the first consideration at all times and occasions. For the reformation of the ballast, after adopting the LED lamp, the ballast is no longer needed. Therefore, it is necessary to directly remove the wiring and ballast from the circuit, and connect the LED lamp directly to the grid, because the LED lamp has its own driving power supply, which converts AC power into DC power and then supplies power to the LED light source.

If the existing MH canopy light originally had a lens, the LED replacement light will be completely packed. The lens helps to spread the light more evenly throughout the venue, but the heat dissipation efficiency will be reduced accordingly. When operating in a well-ventilated open luminaire, LED bulbs are more likely to reach their expected life.

So we recommend removing the lens, because this can solve the heat dissipation problem very well, but new problems also follow, that is, glare or uncomfortable brightness. However, we only need to carry out reasonable lighting design, and it is not difficult to find a reasonable solution.

Regardless of whether there is a fixed lens, when the LED replaces the metal halide, the light distribution pattern may change. We can try to install a few LED lights in warehouses, tunnels or parking lots, and use related light meters to test the degree of change.

There are often many floors and very high shelves in a warehouse. Measuring the difference between the lumens level and light distribution of the LEDs at the top and bottom of the stack will help us to design a more reasonable lighting plan.

In the final decision whether to replace the metal halide canopy light with LED light, we all need to carefully consider these issues. Different occasions have their own unique lighting requirements. These requirements may or may not need to be changed to LEDs.

Therefore, we recommend to install several replacement LED lights to compare and test, analyze the initial installation cost, light distribution changes and glare and other factors. At the same time, the labor costs incurred when replacing lights in the future and the energy costs that can be saved after replacing with LED lights must also be considered.