Brief Introduction

LED is a point light source, which is different from energy-saving lamps or incandescent lamps currently on the market. As the name suggests, the point light source is the light emitted by a point, and the light emitted by this point also has another important feature, that is, there is light only in one direction (all traditional back reflectors have no meaning for the LED itself).

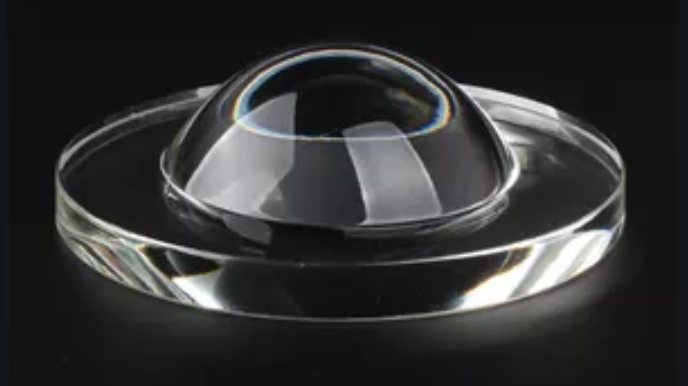

If we want to use this special light for illumination, we must process this light to achieve our requirements and goals. Therefore, we have to add optical design to change this relatively concentrated point light source. Astigmatism with a certain angle, this is the familiar straw hat LED.

Straw hat LED is a form of packaging that is professionally used in lighting design. On the one hand, it can change the light from a concentrated point light source into an astigmatic light source with a certain angle. On the other hand, it has less light attenuation effect and allows more light to be transmitted out for our use.

Although the straw hat LED has made a qualitative leap in optical angle, it is still a point light source compared to the familiar surface light source. Because its brightness is too concentrated, if human eyes look directly at the light source, it will still cause some damage to our eyes.

Therefore, in the application of LED lighting to household lighting, we have to further process the light, and add a certain optical design, so as to achieve the purpose of direct observation by the human eye, while softening the light. On the other hand, we need to magnify the illumination angle again. Although the straw hat LED itself has achieved a range of 120 degrees, if it is directly applied to home lighting, it will give us the feeling that the roof is completely dark. The transparent cover disperses the light again to adapt to normal home lighting.

The Difference Between High-power and Low-power LEDs

With the continuous development of LED technology, people have developed a single LED chip with increasing power to adapt to large-area lighting. At present, the world’s forefront can achieve a single LED power of more than 200W, although the power can be Great, but its price/performance ratio is not good. Let us take several common LEDs as an example to do an analysis.

At present, a large amount of the industry uses a single 0.06W power, and its brightness can reach 7LM. We temporarily calculate it according to the ordinary 6LM. If the power is to reach 1W, we need to use 17 same LEDs with a total brightness. It is 17*6=102LM, which means that 100LM/W can be achieved. If we use a single chip with 1W power, the output brightness can reach up to 80LM, and the commonly used one is generally around 60LM. This is one of the brightness. The main difference, it can be seen that for home use, we still have to choose low-power LEDs.

From the perspective of product cost, the cost of high-power LEDs is higher than the cost of low-power. This comes from two aspects. One is the cost of the LED itself, and the other is that high-power LEDs need to be equipped with aluminum heat sinks. The circuit board, coupled with natural heat dissipation, can meet the requirements.

From the perspective of future maintenance costs of the product, if our lamps fail during use, you can find any electrical repair shop to replace the damaged LED. The cost of a 0.06W LED is at most 1 yuan, plus the maintenance fee does not exceed 5 yuan, if it is to replace a 1W LED, the LED cost will be 8 yuan, plus the maintenance cost will be about 15 yuan. Relatively speaking, low-power LEDs can be purchased in any electronic market, while high-power LEDs may not be available everywhere.

LED to high power is a market trend and the mainstream of future development. However, because the technology has not yet reached the desired result, from a technical point of view, it is currently not suitable for home lighting.

Importance of Thermal Design

The LED itself is a semiconductor device, and all semiconductor devices have certain temperature requirements for normal operation, including ambient temperature and operating temperature. Generally, the ambient temperature for normal operation of semiconductor devices is lower than 80 degrees. When the temperature of the PN junction inside the LED reaches 140 degrees, it will fail.

During normal operation, its own temperature will be emitted through the pins or dedicated base, and then emitted to the surrounding air through the circuit board or aluminum substrate connected to the pins to ensure the normal operation of the LED.

Generally speaking, the power of a single chip is greater than 0.2W, and aluminum substrates must be used for heat dissipation, and aluminum shells and aluminum heat sinks must be added for high power. Of course, this is related to the number and density of LEDs in the entire lamp, and the heat dissipation design should also be considered for low-power LEDs that are too concentrated. This is like every electronic product around you, such as: televisions, monitors, computer hosts, etc. Incorrect heat dissipation design will directly lead to shortened LED life and speed up light decay.

- At present, most of the upper limit of junction temperature can reach about 120 degrees, and the current creep should be regarded as higher, which is 150 degrees.

- The thermal resistance of the lamp bead varies according to the structure of the packaging material. Some multi-chips are as high as tens, and single-chips are generally single digits, at most a dozen. Of course, this is directly related to the junction temperature, which is related to important parameters such as LED life and light efficiency.

- At present, the design life of most LED lamps is 20000~50,000H, which is determined by many factors. First of all, the life of IC, etc., limits the life of the entire lamp.

- From the perspective of heat dissipation, the structural layout is actually the problem of contact thermal resistance and heat conduction bottleneck, which involves a lot and is not easy to list. In general, the structure is integrated, and large areas are in good contact. The lamp beads on the PCB should be distributed as evenly as possible to avoid concentration of heat sources.

- Of course, the higher the driving efficiency, the better. In the layout, the principle of the largest heat source is as far as possible, that is, the LED lamp beads can be filled with glue to achieve the effect of heat dissipation and insulation.

Comprehensive consideration: The temperature rise of a good heat dissipation design should be controlled below 35 and the junction temperature below 80. The theoretical life is more than 50,000.

Current Heat Dissipation Design Challenges

- Natural heat dissipation is too limited by space (radiation heat dissipation itself has little effect and is limited by space size).

- The space for improvement of natural heat dissipation area is limited (limited heat dissipation by convection).

- At present, metal parts are used as radiators, and heat conduction in a small space is sufficient. (The temperature difference of the radiator is small, and the effect of thermal conductivity is small).

- Most of the heat dissipation design can only focus on lamp bead selection, heat dissipation area, interface contact thermal resistance and radiation heat dissipation. Almost a dead end.

- The current situation, the breakthrough point of heat dissipation design is the heat dissipation design of the lighting system, which is the result of a combination of actual manufacturing, material accessories, structural modeling and various experiences in heat dissipation design.