Brief Introduction

As the fourth generation light source, LED (light emitting diode) has great development prospects because of its advantages of energy saving, environmental protection and long life. But because LED is very sensitive to temperature, the rise of junction temperature will affect the life, luminous efficiency, light color (wavelength), color temperature, light shape (light distribution), forward voltage, maximum injection current, luminosity, chromaticity, electrical parameters and reliability of LED. In this paper, the influence of temperature rise on the photoelectric parameters and reliability of LED is analyzed in detail, so as to facilitate the development of LED chips and devices design and development of LED lighting products.

High temperature will cause permanent damage to LED

(1) When the working temperature of LED exceeds the chip’s bearing temperature, the luminous efficiency of LED will decrease rapidly, resulting in obvious light decay and damage.

(2) Most of the LEDs are packaged with transparent epoxy resin. If the junction temperature exceeds the solid phase transition temperature (usually 125 ℃), the packaging material will transform to rubber and the coefficient of thermal expansion will rise sharply, resulting in open circuit and failure of the LED.

Temperature Rise Will Shorten the Life of LED

The life of LED is represented by its light decay, that is, as time goes by, the brightness becomes lower and lower until it finally goes out. Generally, the time of LED luminous flux attenuation of 30% is defined as its lifetime. Generally, the reasons for LED light decay are as follows:

- defects in LED chip materials will proliferate and propagate rapidly at high temperature until they invade the luminous region, forming a large number of non radiative composite centers, which seriously reduces the luminous efficiency of LED. In addition, at high temperature, the micro defects in the material and the fast expanding impurities from the interface and the electric board will also be introduced into the light-emitting region, forming a large number of deep energy levels, which will also accelerate the light decay of LED devices.

- At high temperature, transparent epoxy resin will be denatured and yellow, which affects its light transmission performance. The higher the working temperature is, the faster this process will go on, which is another main reason for LED light decay.

- The light decay of phosphors is also one of the main reasons for LED light decay, because the phosphors decay seriously at high temperature. Therefore, high temperature is the main cause of LED light decay and shorten LED life.

Different brands of LED light attenuation is different, usually led manufacturers will give a set of standard light attenuation curve. For example, the light decay curve of Luxeon K2 from Philips lumiled company shows when the junction temperature increases from 115 ℃ to 135 ℃, its lifetime will be shortened from 50,000 hours to 20,000 hours.

The LED luminous flux attenuation caused by high temperature is irrecoverable, and the luminous flux before irrecoverable light attenuation does not occur is called the “initial luminous flux” of LED.

The increase of temperature will reduce the luminous efficiency of LED

The reasons for the influence of temperature on LED luminous efficiency include the following aspects:

(1) with the increase of temperature, the concentration of electrons and holes will increase, the band gap will decrease, and the electron mobility will decrease.

(2) as the temperature increases, the radiation recombination probability of electrons and holes in the potential well decreases, resulting in non radiation recombination (generating heat), thus reducing the internal quantum efficiency of LED.

(3) the rise of temperature causes the blue wave peak of the chip to shift to the long wave direction, so that the emission wavelength of the chip does not match the excitation wavelength of the phosphor, and also reduces the extraction efficiency of the white LED external light .

(4) with the increase of temperature, the quantum efficiency of phosphor decreases, the light output decreas es, and the external light extraction efficiency of LED decreases.

es, and the external light extraction efficiency of LED decreases.

(5) the performance of silica gel is greatly affected by the ambient temperature. With the increase of temperature, the thermal stress inside the silica gel increases, resulting in the decrease of the refractive index of silica gel, which affects the light efficiency of LED.

In general, the decrease of luminous flux with the increase of junction temperature is reversible. That is to say, when the temperature returns to the initial temperature, the light output flux will have a restorative growth. This is because some parameters of the material will change with the temperature, which will lead to the changes of LED device parameters and affect the light output of LED. When the temperature returns to the initial state, the changes of LED device parameters disappear, and the LED light output will return to the initial state. For this reason, the luminous flux of LED can be divided into “cold lumen” and “hot lumen”, which respectively represent the light output of LED at room temperature and a certain temperature.

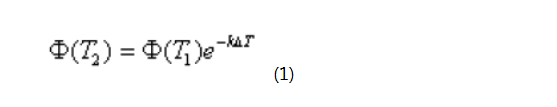

Generally, the relationship between LED luminous flux and junction temperature can be expressed by equation (1)

Among them, Φ(T1) represents the luminous flux (lm) at junction temperature T1, Φ(T2) represents the luminous flux (lm) at junction temperature T2, K is the temperature coefficient (1/℃), and ΔT is the difference in LED junction temperature , ie, ΔT=T2-T1.

In general, the values can be determined by experiments. For example, for InGaAlP based LEDs, the values of △ are shown in Table 1.

|

LED material category |

Temperature coefficient (1 / ℃) |

|

InGaAlP / GaAs @ orange red |

9.52 x 10-3 |

|

InGaAlP / GaAs @ yellow |

1.11 x 10-1 |

|

InGaAlP / GaP @ high bright red |

9.52 x 10-3 |

|

InGaAlP / GaP @ yellow |

9.52 x 10-2 |

(Temperature coefficient of LED with different materials)

The temperature coefficient K of LED light effect should be less than 2.0 × 10-3, so that the LED light output caused by temperature will not be greatly reduced. For example, the optical output of InGaN LED is about 11% lower than that of InGaN led when the junction temperature is 25 ℃.

At present, the temperature coefficients of GaN based white LEDs are mostly between 2.0 × 10-3 and 4.0 × 10-3, and some even reach 5.0 × 10-3. If the K value of LED is too large, we should pay more attention to control the junction temperature.

The influence of temperature on the wavelength (light color) of LED

The emission wavelength of LED can be divided into peak wavelength and main wavelength. The peak wavelength is the wavelength with the largest light intensity, while the main wavelength can be determined by X and Y chromaticity coordinates, reflecting the color perceived by human eyes. Obviously, the change of LED wavelength caused by junction temperature will directly lead to different perception of LED color. For an LED device, the band gap value of the light-emitting material directly determines the wavelength or color of the device. As the temperature increases, the band gap of the material will decrease, resulting in longer wavelength and red shift of the color.

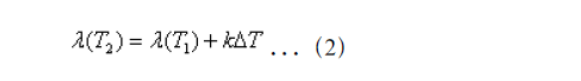

Generally, the variation of wavelength with junction temperature can be expressed as equation (2):

Among them, λ(T2) represents the wavelength (nm) at junction temperature T2, λ(T1) represents the wavelength (nm) at junction temperature T1, K represents the coefficient of wavelength change with temperature, generally 0.1~0.3nm/K ΔT=T2-T1.

Influence of temperature on forward voltage of LED

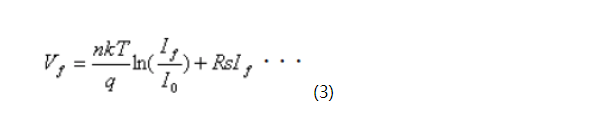

Forward voltage is an important parameter to determine the performance of LED. Its size depends on the characteristics of semiconductor materials, chip size, device junction and electrode manufacturing process. Compared with the forward current of 20mA, the forward voltage of InGaAlP ﹣ LED is 1.8 ~ 2.2V, and that of InGaN ﹣ LED is 3.0 ~ 3.5V. In the small current approximation, the forward voltage drop of LED devices can be expressed by equation (3):

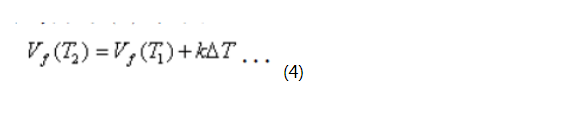

Where Vf is the forward voltage, If is the forward current, Io is the reverse saturation current, q is the electron charge, K is the Boltzmann constant, Rs is the series resistance, and n is a parameter that characterizes the perfection of the P/N junction , Between 1 and 2. On the right side of formula 3, only the reverse saturation current Io is closely related to temperature, and the value of Io increases with the rise of the junction temperature, resulting in a decrease in the forward voltage value Vf. The experiment pointed out that under the condition of constant input current, for a certain LED device, the relationship between the forward voltage drop at both ends and the temperature can be expressed by formula (4):

In formula (4), Vf (T2) and Vf (T1) represent the forward voltage drop when the junction temperature is T2 and T1, respectively. K is the coefficient of voltage drop with temperature, generally between 1.5 and 2.5 mV / K , ΔT= T2-T1.

When the current is fixed, the led forward voltage will decrease when the temperature increases. Because the relationship between forward voltage and temperature is nearly linear, most led thermal resistance testing instruments use this characteristic to measure the thermal resistance or junction temperature.

Too high a temperature limits the maximum injection current of the LED

As the temperature increases, the band gap of the material decreases, resulting in the decrease of the maximum injection current.

In addition, the temperature will also affect the light distribution curve, color temperature and color rendering of LED.

Temperature affects the refractive index of transparent materials, which will change the spatial distribution of LED light, namely the light distribution curve.

If the temperature is too high, the blue light peak will shift, and the phosphor peak will become flat and deteriorated, which will lead to the high color temperature and poor color rendering of LED.

In short, the high-power LED lamp generates a large amount of heat, leading to a high working temperature and a sharp drop in performance. Only by deeply understanding the temperature characteristics of LEDs and developing low thermal resistance LED chips and LED application products can the superiority of LEDs be truly reflected.