The biggest feature of the diffuser is that it causes great interference to the light. No matter how much the light distribution curve of the original design is, as long as the light passes through the diffuser, it will make the beam angle become 160~176°. There is a layer of fog on the surface of the board. From this point, it can be proved that the beam angle is as large as 160~176°. The best proof is that the larger the beam angle, the lower the illuminance. Some will also filter light, making some wavelengths unable to penetrate. , Causing color shift, such as re-light interference treatment on the surface (for example: frosting, embossing), the light transmittance is even lower due to the natural phenomenon of geometric optics, so the base material used to make the diffuser should use the refractive index The lower the better, the lower the interference to light will be.

Types of diffuser

According to the classification of optical principles, there are only two types of diffusers. One is to increase the beam angle and the other is to maintain the original angle.

According to material classification, glass, polystyrene (PS), polycarbonate (PC), polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyethylene terephthalate ( PET), acrylic (PMMA), acrylic (MMA), etc. light-transmitting polymer materials or synthetic materials can be made into diffusion materials for different purposes.

The types of diffuser can be divided into gas diffuser, sound diffuser, liquid diffuser, light diffuser, flavor diffuser, light diffuser, and all materials that can evenly disperse molecules are collectively called diffuser.

Air diffuser –> Generally used to reduce the sound generated by the air flow, such as the muffler of a car.

Sound diffuser –> Generally used to eliminate sound echoes caused by hard objects, such as the wall or ceiling of a concert hall.

Liquid diffuser –> Generally used to turn liquid into mist or smaller molecules to make them evenly distributed, such as water curtains for greenhouses.

Flavor diffuser –> Generally used to eliminate or disperse the flavor to reduce it, such as the canister of a gas mask or the deodorizing canister of a water filter.

Light diffuser –> Generally used to prevent glare and obtain a comfortable environment for vision, such as the diffuser in front of the camera flash.

The Working Principle of the Diffuser

Theoretical basis: When light is emitted from one medium to the smooth interface of another medium, part of the light is reflected by the interface, and another part of the light passes through the interface and is refracted in the other medium. The incident angle of light is equal to the reflection angle, and the reflected light and the incident light are on both sides of the normal in the same plane. This is the law of reflection.

The refracted light conforms to the law of refraction: the refracted light lies in the plane of the incident light and the normal, the refracted light and the incident light are on both sides of the normal, and the ratio of the incident angle to the sine of the refraction angle is a constant. Both the law of refraction and the law of reflection are the basis of geometric optics. They are not only in theoretical research, but also laid a foundation for the development of optical technology and the design of optical products.

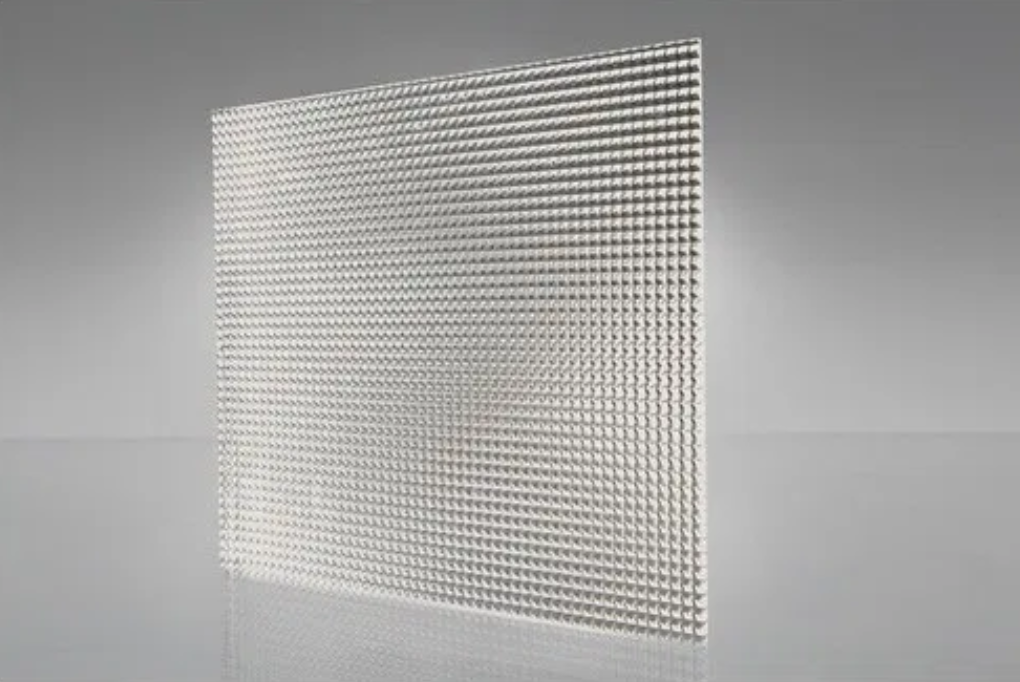

Light diffusion is the use of chemical or physical means to use the physical phenomena of refraction, reflection, and scattering when light encounters two media with different refractive indexes during its course. By adding inorganic or organic light diffusing agents to the base of PMMA, PC, PS, PP and other substrates, or artificially adjusting the light through the array of micro feature structures on the surface of the substrate, the light can be refracted in different directions, reflected and scattered, In this way, the path of light is changed, and the incident light is fully dispersed to produce the effect of optical diffusion. Light diffusers are widely used in liquid crystal displays, LED lighting and imaging display systems.

Optical Characteristics of Diffuser

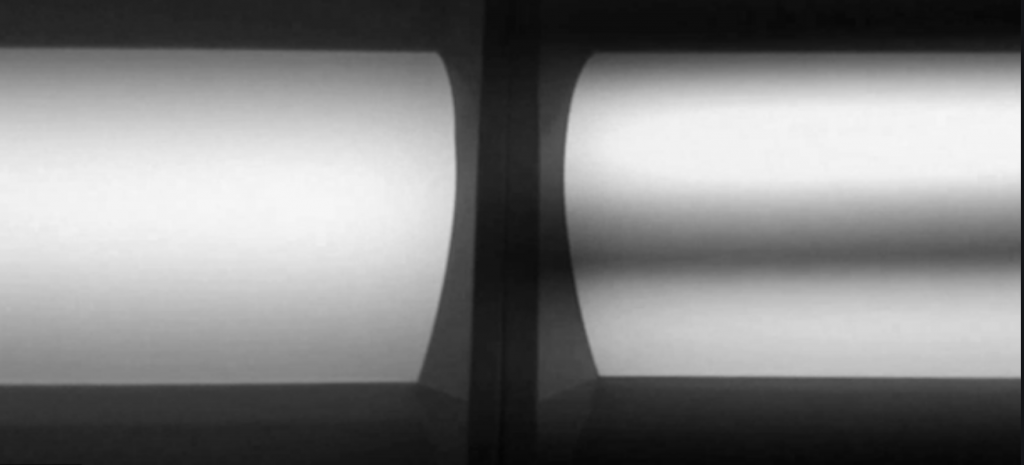

Generally, the optical performance quality control of transparent and translucent plastics such as plate, sheet, film and tube is mainly used to evaluate indicators such as transmittance and haze. Which is defined as follows:

- Light transmittance-the ratio of the luminous flux (Luminous Flux) transmitted through the sample to the luminous flux incident on the sample, expressed as a percentage.

- Haze——The ratio of the scattered luminous flux that deviates from the incident light direction through the sample to the transmitted luminous flux, expressed as a percentage (for this method, only the scattered luminous flux that deviates from the incident light direction by more than 2.5 degrees is used to calculate the haze) . The cloudy or turbid appearance of the interior or surface of a transparent or translucent material due to light scattering. It is expressed as a percentage of the ratio of the scattered luminous flux to the luminous flux through the material. It is an important parameter for the optical transparency of transparent or translucent materials.

- Refractive index-no matter how your light transmittance or haze changes, its quality (density) has already determined its optics. The larger the refractive index, the lower the transmittance, which has nothing to do with the thickness. Both light transmittance and haze are indicators to measure the transparency of materials, and they are not necessarily applicable to diffusers. Generally speaking, there is an inverse relationship between light transmittance and haze, and vice versa.

The above is only the definition of transparent materials. After all, in the 1990s, no country or region made a clear specification for the definition of diffuser. Even in 2014, there was no formal specification. This term originated from the direct-illuminated backlight module, so the diffuser cannot be fully quoted by the transparent plate specification, nor is it a standard established by a certain country, so it may not be applicable to solid-state lighting. With the development of LED light source and LED lighting, its application has presented a technical bottleneck.

Detection Method of Diffuser

- Illuminance meter. This kind of instrument is cheap, convenient and portable. However, due to the interference of natural light from the outside, the measured value will generally be higher. This kind of instrument is only suitable for reference, it is suitable for comparison, and cannot be used as an accurate instrument.

- Light transmittance and haze tester: This kind of instrument is less affected by the outside world during the test, so the test result is lower and more accurate than the illuminance meter. Generally, diffuser plate manufacturers use this type of instrument to test the light transmittance and haze of their products. .

- Integrating sphere: The light transmittance of the integrating sphere test diffuser is very accurate, and it is hardly affected by the external environment. Therefore, the data obtained by testing with the same plate is lower than the above two. Because the instrument is more expensive, there is only a large one. Lighting companies use this equipment to detect light transmittance. (Note: Factors such as the size of the integrating sphere, its placement, the distance from the probe, and the angle between the probe and the light source will affect the test result).

- Light intensity distribution: The light intensity distribution is an indicator tool for whether a lamp has commercial value, because it is the only way to measure all the optical integrity of one-to-one lamps. Some of the other tools above are only the measurement of light molecules or the definition of a material. When this material is added to this lamp, it can only be used to measure whether it complies with the regulations of the International Lighting Association.

Therefore, in view of the different detection instruments used, the measured light transmittance is different, you must ask what kind of instrument is used to detect the light transmittance when selecting the diffuser. Because the result measured in this way is not far from the product you expect.

Application Field of Diffuser

The light diffusion plate is widely used in liquid crystal display, LED lighting and imaging display systems. Its main function is to fully diffuse the incident light to achieve a softer and uniform illumination effect.

- The diffuser is applied to the liquid crystal display

Applied to the direct-lit backlight system used in LCD TVs, the diffuser has good properties such as heat resistance, dimensional stability, mechanical strength, flame resistance, etc., and has a high light transmittance, excellent shielding and durability, so Its light diffusion effect reaches the best condition, which is most suitable for direct type backlight unit

Product Features

Light source diffusibility: suitable for direct-lit backlight modules, with high brightness and high diffusibility, which can improve the diffusion effect of the uniform light distribution of the backlight.

Light transmittance: Excellent light transmittance produces high brightness.

Dimensional stability: the water absorption rate is the smallest, it can still maintain good dimensional stability in a humid environment, and can be used normally in the temperature range of -40℃~125℃.

Antistatic property: It has good surface antistatic property to prevent dust adsorption.

- Light diffuser is used in lighting

Requirements of light diffuser for LED lighting:

- Best diffusion performance: high light softness;

- High light transmission performance: reduce energy consumption and increase the illuminance of the lamp;

- Impact on the light source: maintain the consistency of the color temperature of the light source.