Commonly Used LED Drive Power

1. Common LED driver power

There are many types of LED power supplies, and the quality and price of various types of power supplies vary greatly, which is also one of the important factors affecting product quality and price.

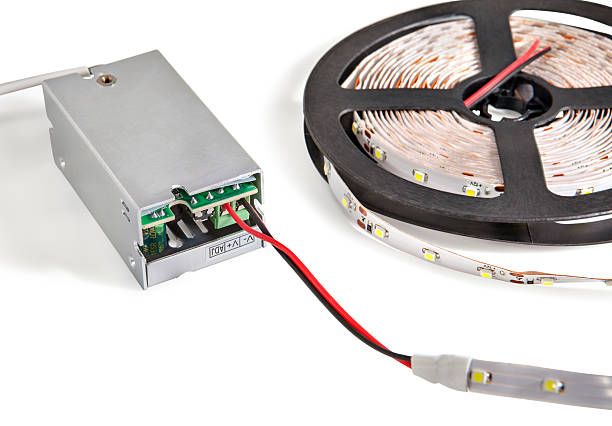

LED drive power can usually be divided into three categories, one is switching constant current source, the other is linear IC power supply, and the third is resistance-capacitance step-down power supply.

2. Switch constant current source

The switching constant current source uses a transformer to convert high voltage into low voltage, and performs rectification and filtering to output stable low-voltage direct current.

The switching constant current source is divided into isolated power supply and non-isolated power supply. Isolation refers to the isolation of output high and low voltage, and the safety is very high, so the insulation requirements of the casing are not high.

Non-isolated safety is slightly worse, but the cost is relatively low. Traditional energy-saving lamps use non-isolated power supplies and are protected by insulating plastic casings.

The safety of switching power supply is relatively high (generally output low voltage), and the performance is stable. The disadvantage is that the circuit is complicated and the price is high.

The switching power supply technology is mature and the performance is stable, and it is the mainstream power supply of LED lighting at present.

3. Linear IC source

Linear IC sources usually use one IC or multiple ICs to distribute voltage, with few types of electronic components, very high power factor and power efficiency, no electrolytic capacitors, long life, and low cost.

The disadvantage is that the output high voltage is not isolated, and there is stroboscopic, so the shell is required to be protected against electric shock.

The market claims that there are no (removed) electrolytic capacitors, and the ultra-long life is all using linear IC power supplies.

The IC drive power supply has the advantages of high reliability, high efficiency and low cost, and is an ideal LED drive power supply in the future.

4. RC step-down power supply

The RC step-down power supply uses a capacitor to provide driving current through its charging and discharging. The circuit is simple and the cost is low, but the performance is poor and the stability is poor. It is easy to burn out the LED when the grid voltage fluctuates. At the same time, the output high voltage is non-isolated and requires insulation protection. shell.

Because of its low power factor and short life, it is generally only suitable for economical low-power products (within 5W).

For high-power products, the output current is large, and the capacitor cannot provide large current, otherwise it is easy to burn out.

In addition, the country has requirements for the power factor of high-power lamps, that is, the power factor of more than 7W is required to be greater than 0.7, but the resistance-capacitance step-down power supply is far from reaching (generally between 0.2-0.3), so high-power products should not be used. Resistor-capacitor step-down power supply.

On the market, almost all low-end products with low requirements use RC step-down power supplies, and there are some cheap low-end products with high power that also use RC step-down power supplies.

5. The difference between LED switching power supply and driving power supply

In a nutshell, LED driver is also a type of switching power supply, but it has several special features and is also the commonality of this type of switching power supply, so it is customary to classify it as LED driver.

These particularities are:

(1) Its voltage output is a multiple of 3.2.

That is to say, the form of voltage output is 3.2V, 6.4V, 9.6V, 12.8V, but generally no more than 25.6V.

Because after this number is exceeded, when the LED is turned on, there will be a possibility of instantaneously burning the last LED that is turned on due to poor product consistency.

And this voltage is not constant, it changes with the change of the load to achieve the purpose of constant current.

(2) Its output current is constant.

The ideal circuit is that no matter how the characteristic curve of the LED changes, the current of the driving power supply remains unchanged.

However, limited to the accuracy of the components, there will still be a small amount of change, and this change is also an important parameter for judging whether the drive circuit is excellent. The function of LED conduction and voltage is a nonlinear “three-stage” relationship, so it is very important to maintain constant current. important.

(3) Its start is soft start.

Since the consistency of the LED is very poor, and the activity of the internal PN junction changes instantaneously when it is turned on, the drive of the LED is generally designed to be soft-started to avoid this defect.

(4) Its circuit requirements are the simplest.

Because many times, the circuit is required to be installed in a small space to match the convenience of LED lighting, so the circuit should be as simple as possible, which can also save costs and reduce energy consumption.

(5) It generally does not require isolation.

Because many products are similar in structure to ordinary lighting, the safety aspect can be similar to lighting.

But this first item is an “optional reading”. Don’t misunderstand when you understand it, because some drivers still need to be isolated. This feature is only applicable to our current popular circuits, not necessarily suitable for future circuit development needs. .

In summary, it can be considered that: soft start, constant current, step voltage, and simple circuit are its characteristics.

6. Special emphasis

Many people unilaterally emphasize constant current, but do not mention voltage, which is wrong.

Because the concept of constant current has nothing to do with voltage, such as a power supply, if it is only a constant current output of 30V, then when you open the circuit, its voltage is 30V.

At this time, if you connect an LED, the component that works directly with the PN junction will burn out before the most accurate circuit can respond.

Because any circuit needs a reaction time, and the working device in the circuit is the semiconductor.

The PN junction can only react after the power supply gives a sampling signal, and the PN junction of the LED starts to work directly, so its “response” is faster than the “many PN junction coordination” in the circuit, and it is burned out in advance!

Of course, there are also special occasions that use this kind of driver, but this kind of LED driver does not allow the output end to be open.

To be precise, it is “not allowed to open the output and then connect the LED”.