The following are several factors that outdoor lighting designers must consider when designing outdoor LED lamps——

1. Outdoor working environment

Outdoor lighting designers must consider the working environment of outdoor LED lamps

LED outdoor lighting fixtures are affected by natural conditions such as temperature, ultraviolet rays, humidity, rain, sand, and chemical gases due to their complex working environment. Over time, it will cause serious problems with LED light decay. So in summary, outdoor lighting designers should consider the impact of these external environmental factors on LED outdoor lighting fixtures when designing.

2. Choice of heat dissipation material

Matters needing attention in the selection of heat dissipation materials for outdoor LED lamps:

The shell and the heat sink are designed as a whole to solve the heating problem of the LED. This method is better. Generally choose aluminum or aluminum alloy, copper or copper alloy, and other alloys with good thermal conductivity. The heat dissipation includes air convection heat dissipation, strong wind cooling heat dissipation and heat pipe heat dissipation. (Air jet cooling heat dissipation is also a kind of heat dissipation similar to heat pipe heat dissipation, but the structure is more complicated.)

The choice of heat dissipation method has a direct impact on the cost of the lamp. It should be considered comprehensively, and the best solution should be selected in conjunction with the designed product.

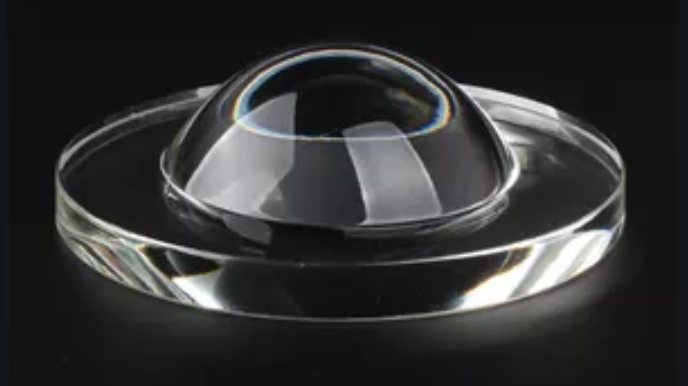

The design and selection of the lampshade is also very important. Transparent plexiglass and PC materials are currently used. The traditional lampshade is made of transparent glass. The choice of material for the lampshade is related to the product grade and positioning of the design. Generally speaking, the lampshade of outdoor lamps is best made of traditional glass products, which is the best choice for manufacturing long-life, high-end lamps.

Lampshades made of transparent plastic, plexiglass and other materials are better for indoor lamps, but they have a limited life when used outdoors. Because of outdoor sunlight, ultraviolet rays, sand, chemical gases, and changes in temperature between day and night, the lampshade ages and shortens its lifespan. Secondly, it is contaminated and difficult to clean, which reduces the transparency of the lampshade and affects the light output.

3. Packaging technology of outdoor LED chips

At present, most of the LED lamps (mainly street lamps) produced by manufacturers are assembled with multiple 1W LEDs in series and parallel. This method has higher thermal resistance than products with advanced packaging technology, and it is not easy to produce high-quality lamps.

Or use 30W, 50W or even larger modules for assembly to achieve the required power. The encapsulation materials of these LEDs are encapsulated with epoxy resin and encapsulated with silica gel. The difference between the two is: epoxy resin encapsulation has poor temperature resistance and is easy to age over time. Silicone encapsulation has better temperature resistance, so you should pay attention to the selection when using it.

The general opinion in the LED lighting industry is that it is better to use multiple chips and a heat sink as a whole package. Or use aluminum substrate multi-chip packaging and then connect to the heat sink through phase change material or heat dissipation silicone grease. The thermal resistance of the product is one or two less than the thermal resistance of the product assembled with LED devices, which is more conducive to heat dissipation.

For lamps using LED modules, the module substrate is generally a copper substrate, and its connection with the external radiator should use a good phase change material or a good heat dissipation silicone grease to ensure that the heat on the copper substrate can be transferred to the external radiator in time superior. If it is not handled well, it is easy to accumulate heat and cause the temperature of the module chip to rise too high, which affects the normal operation of the LED chip. Multi-chip packaging is suitable for manufacturing general lighting fixtures, and module packaging is suitable for manufacturing compact LED fixtures where space is limited (such as the headlights of automobile main lighting, etc.).

4. Radiator design

Research on the design of outdoor LED lamp radiator:

The radiator is a very critical part of the LED lamp. Its shape, volume, and heat dissipation surface area must be designed well. If the radiator is too small, the working temperature of the led lamp is too high, which will affect the luminous efficiency and lifespan. If the radiator is too large, the consumption of materials will increase the cost and weight of the product, which will reduce the competitiveness of the product. Therefore, it is very important to design a suitable LED light radiator. The design of the radiator has the following parts:

1). Clarify the power that the LED light needs to dissipate.

2). Some parameters for designing heat sinks: specific heat of metal, thermal conductivity of metal, chip thermal resistance, heat sink thermal resistance, ambient air thermal resistance, etc.

3). Determine the type of heat dissipation (natural convection heat dissipation, strong wind cooling, heat pipe heat dissipation, and other heat dissipation methods). In terms of cost comparison: natural convection cooling has the lowest cost, strong wind cooling is medium, heat pipe cooling has a higher cost, and air jet cooling has the highest cost.

4). Determine the maximum allowable operating temperature of the LED lamp (ambient temperature plus the allowable temperature rise of the lamp),

5). Calculate the volume and heat dissipation area of the radiator, and determine the shape of the radiator.

6). Combine the radiator and the LED lamp to form a complete lamp, and power on and work for more than eight hours. Check the temperature of the luminaire at a room temperature of 39°C–40°C to see if it meets the heat dissipation requirements to verify that the calculation is correct. If the conditions of use are not met, the parameters must be recalculated and adjusted.

7). The seal between the radiator and the lampshade should be waterproof and dustproof. The anti-aging rubber pad or silicon rubber pad should be placed between the lampshade and the radiator, and the stainless steel bolts should be used to fasten it to ensure the seal, waterproof and dustproof.

Through the above four points of attention, and then refer to the latest international outdoor lighting technical specifications, and urban road lighting design standards, this is the most basic knowledge necessary for outdoor lighting designers.