Brief Introduction

In daily life, it is often seen that solar street lights are used as lighting tools on both sides of the road. From the outside, you won’t see batteries with energy storage, only panels that collect solar energy. But at night, the power of the energy storage battery will be used to provide power for the street lights and illuminate the road. Therefore, when we understand solar street lights, we also need to know the type of energy storage battery and its installation.

Types of Energy Storage Batteries for Solar Street Lights

How the battery works

The solar photovoltaic power generation system directly converts solar energy into electrical energy using solar cells made of the principle of photovoltaic effect. A solar cell is the smallest unit for photoelectric conversion. Its size is about 4 square centimeters to 100 square centimeters.

The working voltage of a single solar cell is 0.45-0.50 volts, which generally cannot be used as a power source alone. The solar cells are connected in series, parallel and encapsulated to become solar cell modules. Its power ranges from a few watts to hundreds of watts and can be used as a power supply alone.

The solar cells are connected in series, in parallel and mounted on the bracket to form a large solar cell array. It can output hundreds of watts, several kilowatts or more, and is an electrical energy generator for photovoltaic power plants.

Classification of solar cells

Commonly used solar cells are mainly silicon solar cells. There are currently three commercialized silicon solar cells in the world: monocrystalline silicon solar cells, polycrystalline silicon solar cells and amorphous silicon solar cells.

Monocrystalline silicon solar cells are currently the fastest developing solar cells. Its structure and production process have been finalized, and its products have been widely used in space and ground. This solar cell uses high-purity single-crystal silicon rods as raw materials, with a purity requirement of 99.999%. In order to reduce production costs, solar-grade monocrystalline silicon rods are now used in ground-based solar cells, and the material performance indicators have been relaxed.

Monocrystalline silicon solar cells have the highest manufacturing cost, but also the highest photoelectric conversion efficiency, the highest reaching 24%.

At present, the polycrystalline silicon materials used in polycrystalline silicon solar cells are mostly aggregates containing a large number of single crystal particles, or are made of waste single crystal silicon materials and metallurgical grade silicon materials by melting and casting, and then poured into graphite molds. After slowly solidifying and cooling , that is, polycrystalline silicon ingots.

This silicon ingot can be cast into cubes for slicing into square solar cells, which can improve material utilization and facilitate assembly. The manufacturing process of polycrystalline silicon solar cells is similar to that of monocrystalline silicon solar cells. Its photoelectric conversion efficiency is about 12%, which is slightly lower than that of monocrystalline silicon solar cells. However, its material is easy to manufacture, saves power consumption, and the total production cost is low, so it has been greatly developed.

Battery Installation

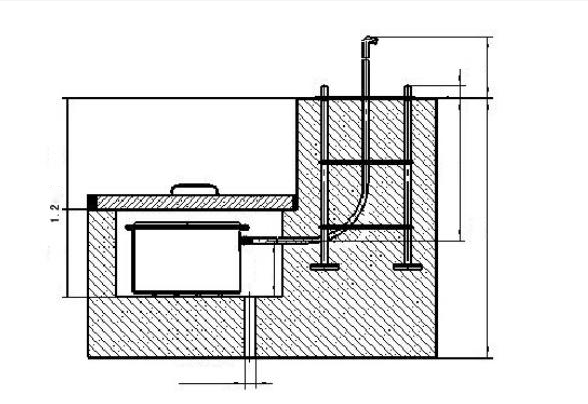

In order to ensure the service life of the battery, according to the local ground temperature data, the battery is first placed in a special moisture-proof buried box, and then placed in a cement pool at a depth of 1.2 meters (the net height of the cement pool is 0.5 meters). The top of the cement pool is covered with a 5CM thick cement prefabricated board. Finally, the cement board steel bars and the light pole base steel bars are welded, filled with soil and compacted.