How to Choose the Right Lighting Equipment for Special Scenes

1. The importance of choosing different types of flood lights in special scenes

In modern life, whether it is home or outdoor, stadium and other large places, flood lights have been widely used. flood lights can be seen in common scenes such as roads, streets, and parking lots. It can be said that flood lights have been integrated into people’s lives and become one of the indispensable tools.

But what is unexpected is that the applicable scenes of flood lights are far more than these common places in life. In fact, flood lights can also be used in many extreme environments, such as high temperature environments, low temperature environments, underwater environments, and even those places that may be dangerous, such as warehouses where flammable and explosive materials are stored.

The utility of flood lights is so powerful and widespread, let’s take a look at how it works in special scenes.

2. High temperature scene & low temperature scene

2.1. High temperature scene

High temperature means the lighting that functions under the extreme hot environment. The flood light should be designed for industrial use such as chemical plants, foundry, food processing factory and etc. Unlike other conventional HIDs, LED lights give extra stability and durability under high ambient temperature. It is not the best option to use halogen or fluorescent inside such the tough environment because the volatile chemical inside the tubes will become very unstable in such the burning environment and thus its lighting efficiency drops significantly. On the contrary, LED uses solid-state electronics which does not involve delicate filament and the mercury vapor. The components keep in stable condition even under 100°C. That is the reason why LED light is frequently adopted in factory, foundry, and other industrial sites.

In response to this situation, we have launched some self-developed flood lights such as high bay, low bay, flood lights and work lights, having power ranged from 100 to 500 watt. All our LED lighting solutions passes the high ambient temperature test under 100°C (212°F). For 80°C /176°F heat-proof, we offer some molds like LS-FLN08-8-100 (100W); LS-FLN08-8-200 (200W); LS-FLN08-8-300 (300W); LS-FIN08-8-500 (500W). For 100°C/ 212°F heat-proof, we can also offer some molds like LS-FLN08-10-100 (700W); L5-FLN08-10-200 (200W); LS-FIN08-10-300 (300W); LS-FLN08-10.500 (500W). All these molds are packing with our patented heat dissipation system effectively conducts the heat inside the light body away, in order to maintain the junction temperature at a lower range. And before leaving the factory, we will test each light for 100°C heat resistance.

2.2. Low temperature scene

In the application process of LED lights, we will find that in winter, some outdoor lights are used normally in East China, but in North China, especially in Northeast China, there are problems such as failure to light up, abnormal lighting, etc. This is because LED lights were not considered at the beginning of the design. In this chapter, we will explain the influence of low temperature on LED lights, as well as the low temperature evaluation methods and examples of LED lights. The low temperature scene to which the flood light is applied is generally a cold storage, so here we take the cold storage scene as an example.

The main characteristics of the cold storage place are low temperature, high humidity and freezing phenomenon, so the cold storage light must also be used according to the standard protection level. Whether it is an old cold room or a lot of new cold rooms, incandescent lights or energy-saving lights with low luminous efficiency and short life are used as lighting fixtures in the warehouse. Ordinary cold storage lighting in the low temperature and humid environment of the cold storage, the general light life is about 50-60 days, and the overall life of the high-quality LED cold storage special light is extended to 3-5 years, which greatly improves the life. In order to avoid the potential safety hazards caused by moisture and short circuit, LED cold storage lights have the characteristics of “moisture-proof”, “dust-proof”, “crack-proof” and “low temperature resistance”.

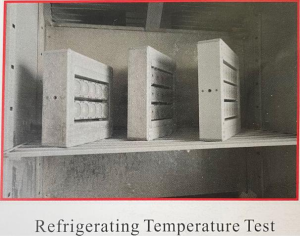

The selection of cold storage lights is usually based on the power of the light, the irradiation area, the voltage, the material, the waterproof level, the temperature and humidity, and other parameters. No matter how you choose, the cold storage light must be resistant to low temperature, water-proof, dust-proof, and crack-proof, otherwise the life span is very short. In response to such needs, most of our outdoor flood lights have the characteristics of low temperature resistance, and can withstand the low temperature of -25°C. Similarly, the refrigerating temperature test will be carried out before leaving the factory, and consumers can choose with confidence!

3. Underwater scene

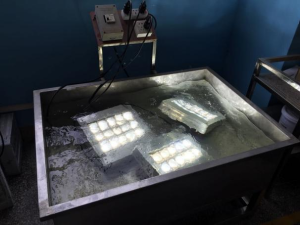

LED underwater lights, as the name suggests, are lights used for underwater operations, with exquisite appearance and elegant appearance. It is widely used in various sightseeing places such as swimming pools, fountain pools, pools, theme parks, square parks and so on. It can also be used as the best choice for commercial and artistic lighting. The decorative effect is excellent, and the highly ornamental LED underwater lights make the night more colorful. Underwater lights have multiple uses, so their design and manufacturing requirements are more stringent. In terms of safety performance, since the lights are installed underwater, the underwater lights need to use low-voltage power supply, which effectively prevents the risk of electric leakage and electric shock, and can ensure the safe use of the underwater lights. In addition, LED underwater lights need to be adapted to various places for installation and use. To be flexible and convenient to use, the installation angle should be freely adjusted. Finally, in terms of decorative lighting effects, LED underwater lights are also required to have various lighting effects.

In response to the above needs, we have also designed and developed many models of underwater lights, among which the most popular models are:

LS-FLN-20, LS-FLN-30, LS-FLN-40, LS-FLN-50, LS-FLN-60, LS-FLN-75, LS-FLN-80, LS-FLN-90, LS-FLN-100, LS-FLN-120, LS-FLN-150, LS-FLN-180, LS-FLN-200, LS-FLN-240, LS-FLN-250, LS-FLN-270, LS-FLN-300, LS-FLN-360, LS-FLN-400, LS-FLN-420, LS-FLN-450, LS-FLN-480, LS-FLN-500, LS-FLN-540, LS-FLN-600, LS-FLN-680, LS-FLN-720, LS-FLN-750, LS-FLN-840, LS-FLN-900, LS-FLN-1000. Not only are they passed water anti-leakage test before they leave the factory, they also pass the IP68 test.

4. Hazardous locations

Explosion-proof lights refer to lights that are used in hazardous places where flammable gases and dust exist, and can prevent arcs, sparks and high temperatures that may be generated inside the light from igniting flammable gases and dust in the surrounding environment, so as to meet explosion-proof requirements. Explosion-proof LED flood lights are mainly used for fixed lighting in petrochemical, transfer stations, infield pump rooms, joint stations, power distribution rooms, operation rooms, duty rooms, metering rooms and inflammable and explosive places. Therefore, it must have the following properties and characteristics:

- The shell is made of lightweight alloy materials and the latest surface treatment technology, which is wear-resistant, anti-corrosion, waterproof and dust-proof; the transparent parts are made of imported bulletproof rubber materials, which have high light transmittance and good impact resistance, can make the lights work normally in various harsh environments.

- The surface of the light adopts the latest spraying technology, which does not change color, does not rust, can prevent water spray and rain, and can also be used outdoors for a long time.

- Using the latest green and environmentally friendly high-power white LED solid-state light source, with high luminous efficiency and long life, the life can be as high as 100,000 hours, which can realize long-term maintenance-free, soft and uniform light, no glare, avoid eye fatigue of operators, and improve work efficiency. The power consumption is only 20% of the same luminous flux incandescent light, which is economical and environmentally friendly.

- It is completely designed and manufactured according to explosion-proof requirements, and can work safely and reliably in flammable and explosive dangerous places.

Then when we need to use explosion-proof flood lights, we can choose gas discharge bulbs and high reflectivity mirror reflectors, which have high luminous efficiency, long life, large lighting range and high brightness; metal halide lights and high-pressure sodium lights. A variety of power can be selected according to the actual needs of the working environment, lighting characteristics and light intensity.

The models of explosion-proof lights independently developed by our company are: LS-BUP-60 (60W); LS-BUP-80 (80W); LS-BUP-100 (100W); LS-BUP-120 (120W); LS-BUP-150 (150W); LS-BUP-200 (200W). They are all trustworthy products, and customers can choose according to their own lighting needs.

5. Conclusion

This paper expounds and discusses the application and selection of flood lights in special scenes from three aspects. In different temperature environments, we can choose corresponding products according to the temperature tolerance range of flood lights. For example, in high temperature environment, such as chemical plants, foundry, food processing factory and other places, we can choose flood lights that have passed the extreme heat temperature test, such as our products LS-FLN08-8-100 (100W); LS-FLN08-8-200 (200W); LS-FLN08-8-300 (300W); LS-FIN08-8-500 (500W); LS-FLN08-10-100 (700W); L5-FLN08-10-200 (200W); LS-FIN08-10-300 (300W); LS-FLN08-10.500 (500W). In low temperature environments, such as cold storage, we can choose most of our flood lights that have passed the refrigerating temperature test. If the flood light needs to be installed underwater, such as in pools and fountains, we can choose flood lights that have passed the water anti-leakage test, such as our products LS-FLN-20, LS-FLN-30, LS-FLN-40, LS-FLN-50, LS-FLN-60, LS-FLN-75, LS-FLN-80, LS-FLN-90, LS-FLN-100, LS-FLN-120, LS-FLN-150, LS-FLN-180, LS-FLN-200, LS-FLN-240, LS-FLN-250, LS-FLN-270, LS-FLN-300, LS-FLN-360, LS-FLN-400, LS-FLN-420, LS-FLN-450, LS-FLN-480, LS-FLN-500, LS-FLN-540, LS-FLN-600, LS-FLN-680, LS-FLN-720, LS-FLN-750, LS-FLN-840, LS-FLN-900, LS-FLN-1000. In environments where dangerous situations may occur, such as petrochemical, transfer stations, infield pump rooms, joint stations, power distribution rooms, operation rooms, duty rooms, metering rooms, we can choose flood lights that have passed the explosion-proof test, Such as our products LS-BUP-60 (60W); LS-BUP-80 (80W); LS-BUP-100 (100W); LS-BUP-120 (120W); LS-BUP-150 (150W); LS-BUP-200 (200W).

To sum up, although there are times in our life when we need to use flood lights in less common situations, we still have many choices. These flood lights, which are designed to be used in various scenarios, provide protection for the work of many industries, and also bring convenience to our lives. They are silently contributing to the happy life of the people!