Commonly used light sources in lighting projects include incandescent incandescent lamps and tungsten halogen lamps, low-pressure gas discharge fluorescent lamps and high-strength gas discharge fluorescent high-pressure mercury lamps, metal halide lamps and high-pressure sodium lamps.

Incandescent and Halogen Tungsten Lights

Incandescent

Any light source that works according to the principle of thermal radiation can be called an incandescent lamp. At present, the commonly used incandescent lamps are divided into two categories, namely ordinary incandescent lamps and halogen tungsten lamps.

The incandescent lamp relies on electric energy to heat the filament to incandescence to emit light. When the filament emits light, it also produces a large amount of infrared radiation and a small amount of ultraviolet radiation, which are eventually lost in the form of heat energy. Obviously, if you want to improve the luminous efficiency of incandescent lamps, you should choose high-melting-point materials as filaments and make them work at the highest possible temperature.

(1) The structure of the incandescent lamp

Ordinary incandescent bulbs are composed of tungsten filaments, glass bulbs, lamp holders, brackets, lead wires, etc., filled with argon, nitrogen, or argon-nitrogen mixed gas, the usual working pressure is about 1.013x105Pa, and the ratio of argon-nitrogen is determined by the rated voltage and Depending on the filament temperature, usually incandescent lamps use argon between 86% and 98%.

The filament is the main part of the incandescent lamp that emits light. The commonly used filament shapes include straight filament, single spiral filament, double spiral filament and so on. The shape and size of the filament have a direct impact on the life and luminous efficiency of the incandescent lamp. Tungsten filaments of the same length and thickness are wound into a single helix with high luminous efficiency. The filament structure is compact, the luminous point is small, and the utilization rate is high.

Types of incandescent bulbs: Incandescent bulbs include general bulbs, mushroom bulbs, round bulbs, candle bulbs, reflector bulbs, holiday bulbs and peanut bulbs.

(2) The color temperature and color rendering index of incandescent lamps

The light efficiency of incandescent lamps is low (about 12~17lm/W), and the color temperature is generally 2400~2900K, but the color rendering is higher, and the color rendering index Ra is as high as 99~100. So far, it is the most widely used light source.

Halogen Light

Tungsten halogen lamps are thermal radiation light sources, and their working principle is basically the same as that of ordinary incandescent lamps, but there is a big difference in structure. The most prominent difference is that the gas filled in the halogen tungsten bulb contains some halogen elements or halides.

Tungsten halogen lamps have high luminous efficiency (about 18-21lm/W), low color temperature generally 2700-3300K, high color rendering, and color rendering index Ra as high as 99-100.

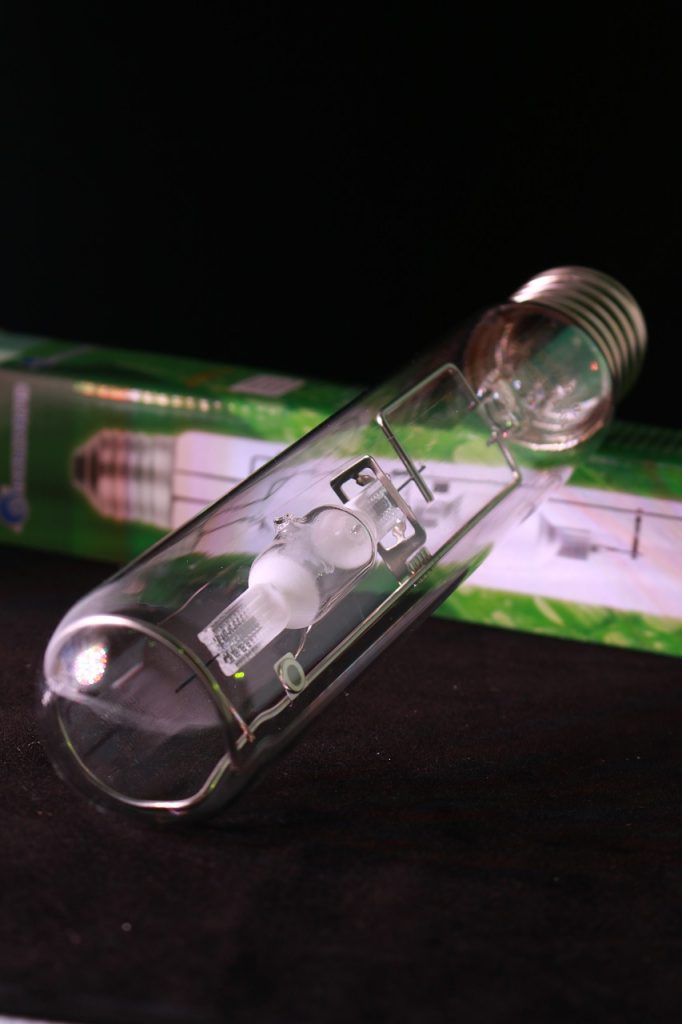

(1) Structure of tungsten halogen lamp

Tungsten halogen lamps are composed of tungsten filaments, glass bulbs filled with halogen, and lamp caps. Tungsten halogen lamps are divided into double-ended, single-ended and double bulbs;

Double-ended tubular tungsten halogen lamp structure: the lamp is tubular, the power is 100~2000W, the diameter of the tube is 8~10mm, and the length is 80~330mm. Magnetic joints are used at both ends, and a fuse is also installed in the magnetic tube when necessary. This kind of lamp is mainly used for indoor and outdoor flood lighting;

In order to make the halide generated at the tube wall in a gaseous state, the tube wall temperature is much higher than that of ordinary incandescent lamps. Correspondingly, the size of the bulb of the tungsten halogen lamp is much smaller, and the temperature is much higher. High temperature quartz glass or high silica glass.

(2) Classification of tungsten halogen lamps

- Tungsten halogen lamps can be iodine tungsten lamps and bromine tungsten lamps according to the different halogens charged into the bulb.

- Tungsten halogen lamps can be divided into hard glass tungsten halogen lamps and quartz glass tungsten halogen lamps according to different bulb shell materials.

- Tungsten halogen lamps can be divided into mains tungsten halogen lamps (220V) and low-voltage tungsten halogen lamps (6V, 12V, 24V) according to the working voltage.

- Tungsten halogen lamps can be divided into double-ended and single-ended tungsten halogen lamps according to the structure of the lamp cap.

(3) Working principle of tungsten halogen lamp

When a bulb filled with a halogen substance is energized, the tungsten evaporated from the filament combines with the halogen in the bulb wall area to form a volatile halogen tungsten compound. The halogen tungsten compound diffuses and moves in the bulb. When it diffuses to the area around the hotter filament, the halogen tungsten compound decomposes into halogen and tungsten. The released tungsten is deposited on the filament, and the halogen continues to diffuse into the bulb with a lower temperature. The wall area combines with tungsten to form a tungsten halide cycle.

The tungsten halogen cycle effectively inhibits the evaporation of tungsten, so the service life of the tungsten halogen lamp can be prolonged, while the filament temperature can be further increased, higher luminous efficiency can be obtained, and the attenuation of luminous flux during use can be reduced.

(4) Working characteristics of halogen tungsten lamps

- Color table and color rendering

Tungsten halogen lamp is a low color temperature light source, and its color temperature is generally between 2800 and 3200K. Compared with ordinary incandescent lamps, the light chromaticity is a little bit cooler, but the color rendering is better, the color rendering index Ra=100;

- Application of tungsten halogen lamp

Pay attention to the following issues when using halogen tungsten lamps:

In order to make the halide generated on the bulb wall in a gaseous state, the tungsten halogen lamp is not suitable for low temperature occasions. When the double-ended tungsten halogen lamp is working, the lamp tube should be installed horizontally, and its inclination angle should not exceed 40, otherwise its service life will be shortened.

Since the tungsten halogen lamp produces high temperature (tube wall temperature 6000C) when it is working, no flammable substances are allowed to be placed near the tungsten halogen lamp, and the lead-in wire of the lamp pin should be a high-temperature wire. In addition, since the filament of the tungsten halogen lamp is slender and brittle, vibration and impact should be avoided when the tungsten halogen lamp is used, and it is not suitable as a mobile lighting fixture.

Fluorescent Light

Fluorescent lamps and incandescent lamps have completely different lighting principles. Fluorescent lamps are a low-pressure gas discharge lamp. The so-called gas discharge refers to the discharge phenomenon when the current passes through the gas medium. Gas discharge phenomena are very common. For example, lightning during thunderstorms in Xiamen, strong light generated when using electric welding machines, etc. are all gas discharge phenomena.

The first use of gas discharge for lighting was a carbon arc lamp produced by energizing a carbon rod. This discharge is not easy to control. Later, people have a deep understanding of the nature of gas discharge. In 1936, it successfully realized the discharge in the closed tube to produce the fluorescent lamp. So far, the fluorescent lamp industry has formed a huge industrial system with many types of products and is still under continuous development. Fluorescent lamps have become the main lighting source.

The Luminous Principle of Fluorescent Lights

The commonly used phosphor for fluorescent lamps is calcium halophosphate; a low-pressure mercury vapor discharge lamp. The atoms of mercury vapor in the tube excite 253.7 nm ultraviolet light during discharge. The ultraviolet radiation is absorbed by the phosphor on the tube wall and converted into visible light. The conversion efficiency and the color of the lamp mainly depend on the type and nature of the phosphor.

Photoelectric Characteristics of Fluorescent Lights

- Voltage characteristics: Changes in power supply voltage will cause changes in various characteristics. Whether the voltage is too high or too low, it will shorten the life of the lamp. Because the power supply voltage increases, the lamp current will increase, the lamp tube will be blackened and the life will be shortened; and the power supply voltage will decrease, the electrode temperature will decrease, the lamp will not be easy to start, and the electrode material will be promoted. Spattering also shortens the lifespan, so the fluctuation range of the power supply voltage must be within ±6 of the rated value. At the same time, the selection and matching of the lamp ballast is also very important.

- Working characteristics of fluorescent lamps

As the lighting time is prolonged, the phosphor will age. At the same time, due to the effect of the remaining impure gas in the tube, the phosphor will be blackened, and the electrode material will be splashed, which will cause the tube end to blacken, and the glass will become black due to sodium evolution. The luminous flux of fluorescent lamps is reduced. Generally, it drops quickly in the first 100h, and then it is relatively slow. The lighting time when the total luminous flux drops below 70% of the initial luminous flux (the fluorescent lamp with high color rendering drops below 60%) is defined as the lamp life.

When the voltage of the fluorescent lamp increases, the working current increases and the electrode temperature increases, which will cause the electrode and the lamp tube to overheat, which will accelerate the evaporation of the negative material and the tube will quickly turn black, resulting in a decrease in life. If the voltage is too low, it will be difficult to start the fluorescent lamp, and the number of starters will increase, which will aggravate the sputtering of the cathode material and shorten the life.

- The influence of ambient temperature on fluorescent lamps

The working characteristics of the lamp also depend on the vapor pressure of the mercury in the tube, so it is also affected by the ambient temperature. When the temperature is too low, the mercury vapor pressure decreases, the mercury atom ionization rate decreases, and it is difficult to start, and the ultraviolet radiation decreases. When the ambient temperature is too high, the mercury vapor pressure in the tube increases, but the ultraviolet rays decrease, and other spectral lines increase. Therefore, both low and high ambient temperature will affect the luminous efficiency of the fluorescent lamp. Fluorescent lights should not be used outdoors.

- The influence of switching times on life

Frequent starting of fluorescent lamps will greatly consume the cathode material, thereby reducing the life span. In general, the life of a fluorescent lamp refers to the total use time of 3 hours each time it is ignited. The longer the continuous working time, the longer the service life. Therefore, it is not suitable to use fluorescent lamps in places where lamps are frequently switched on and off.

- Luminosity and chromaticity characteristics of various fluorescent lamps

In general lighting sources, according to the light color characteristics of fluorescent lamps, they can be classified into daylight color, high color rendering, three primary colors, cool white and warm white, etc.

- The development prospects of fluorescent lamps

The development prospect of fluorescent lamps is quite rapid. The improvement of the lamp tube and the control circuit makes the light efficiency of the lamp tube develop from 35lm/W in 1940 to about 100Lm/W now, and the lamp life from 2000h to 15000h now. The emergence of three primary color phosphors increases the delivery effect of the lamp tube, improves the lumen maintenance characteristics of the lamp tube, and greatly improves the color rendering of the fluorescent lamp. Fluorescent lamps coated with multi-spectral band phosphors have extremely high color rendering (Ra above 90) and high luminous efficiency, which have replaced older lamps.

Before some fluorescent lamps are coated with fluorescent powder, a protective film is applied to the inner wall of the lamp tube. This protective film can prevent the sodium element in the glass tube from diffusing into the fluorescent powder, thereby significantly improving the lumen maintenance characteristics of the lamp. At the same time, the protective film can also reflect ultraviolet rays, which helps to reduce the amount of phosphor. The protective film can also significantly reduce the amount of mercury required in each fluorescent lamp. For example, the mercury injection amount of a T5 straight tube fluorescent lamp is only 3mg.