Introduction

There are several ways to implement white LEDs. At present, the most technically mature one is to coat the blue light chip with yellow and/or red light-emitting phosphors, and through the mixing of blue light and yellow (red) light, white light with different color temperature and color rendering index can be realized. LED.

There are two main ways to achieve high-power white LEDs. One is to directly package high-power LED chips. The second is to combine multiple low-power chips into high-power by packaging.

Multi-chip integrated white LEDs also have unique advantages: through different series-parallel combinations, various rated voltages and currents can be achieved, which can better adapt to driver design, improve overall luminous efficacy and reduce costs. The number of chips per unit area can be more or less, and can be packaged into various point and surface light sources. The main disadvantage is the large size. Due to the multi-point emission, the difficulty of secondary optical design is increased.

Based on the multi-chip integrated high-power white LED, many companies have been researching and developing, and some products have been listed. Based on a large number of experimental studies, this paper mainly elaborates on the aging characteristics, light quality and related driving technologies of integrated power white LEDs.

Aging Characteristics of Multi-chip Integrated High-power LEDs

Comparison of LED light source and other light sources

The entry of white LEDs into general lighting depends on three factors. One is the price, the second is the light efficiency, and the third is the lifespan.

Incandescent lamps have low luminous efficiency and short lifespans, but are very cheap. And because of its low color temperature and good color rendering index, it is still competitive in the market.

Fluorescent lamps are slightly more expensive, have high luminous efficiency, and have a longer lifespan. The disadvantage is that it contains heavy metals, which is not conducive to environmental protection.

We all consider white LEDs as green lighting sources. Through the best matching of chip and phosphor, different color temperature and color rendering index requirements can be achieved. And it is solid luminescence, small size. However, although the current LED chip and packaging level and luminous efficiency are higher than incandescent lamps, they are still far from fluorescent lamps. The price is much higher than that of fluorescent lamps.

The lifespan of white LEDs is not as good as expected. Although the packaging and heat dissipation conditions are different, they are only a few thousand hours.

LED light decay

The study found that the light decay characteristics of white LEDs are closely related to the ambient temperature and heat dissipation conditions. Reducing the thermal resistance from the PN junction to the support (or substrate) and creating good heat dissipation conditions are one of the key technologies to improve LED life.

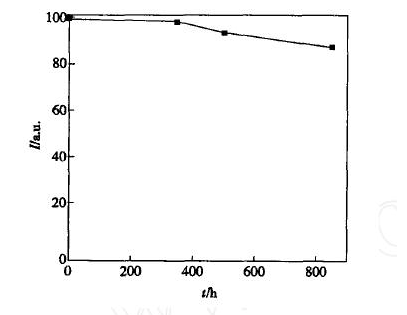

Figure 1 shows the light decay of a multi-chip integrated 1W high-power white LED.

Although the power of the multi-chip integrated white LED is higher, the integrated white LED uses an aluminum substrate with better thermal conductivity and an external heat dissipation mechanism, so that the heat dissipates faster. Therefore, the light decay of 1W high-power integrated white LED is only 12% at 900h.

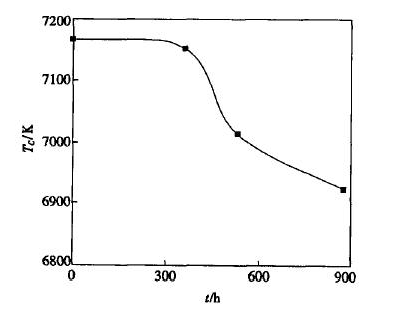

In addition, with the passage of aging time, the stability of color temperature cannot be ignored. Figure 2 shows the variation of color temperature with time. It can be seen that the stability of the color temperature is still good. It shows that the attenuation laws of chips and phosphors are basically the same.

Curve of color temperature as a function of aging time

Light Quality of Multi-chip Integrated High-power White LEDs

The light quality of white LED determines whether it can enter the field of general lighting. Taking the integrated power type 1W white LED as an example, when CCT is 6400K and the color rendering index is greater than 80, the luminous flux can reach more than 30lM. When the color temperature is 3000K and the color rendering index is greater than 80, the luminous flux can reach more than 25lM. The power is the same, the luminous flux is different, and the price is also different.

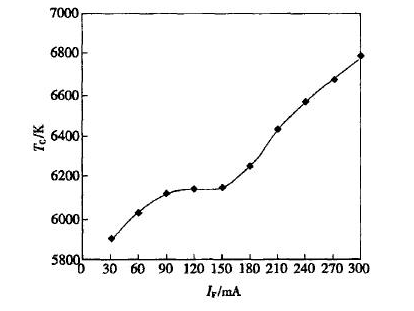

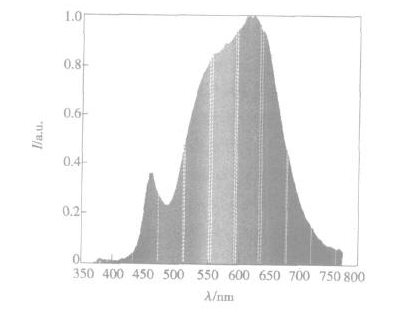

Figure 3 shows the spectral characteristics of an integrated power 1W high-power white LED. The color temperature is 6400K, and the color rendering index is 85. Customers can design secondary optics according to specific conditions to achieve a specific light intensity distribution. The relationship between color temperature and current is shown in Figure 4. It can be seen that different current sizes still have a certain influence on the color temperature.

The effect of temperature on current

When the temperature increases, the forward voltage drop of the LED will decrease with the increase of temperature. If it is driven by constant voltage, the current will increase greatly, which will lead to further increase in temperature and enter a vicious circle. This will seriously reduce the luminous efficiency of the LED and shorten the life of the LED.

Therefore, under normal circumstances, the constant current driving method is better than the constant voltage method. However, for multi-chip integrated high-power LEDs, the use of constant current driving is not necessarily the best driving solution. The reason is that after a certain string of LEDs is short-circuited or open-circuited, the current distribution will be uneven, which will affect the normal operation of the LEDs, accelerate aging, and reduce lifespan.

1w white LED spectrum

The curve of color temperature as a function of current

Drive Circuit

According to the different energy sources, LED driving circuits can be generally divided into two categories. One is AC/DC conversion, where the energy comes from AC mains. The second is DC/DC conversion, and the energy comes from dry cells, rechargeable batteries, accumulators, etc.

According to the different driving principle of LED, we can divide it into linear driving circuit and switching driving circuit. Linear circuits are low cost and cheap, but their efficiency is low, generally not more than 60%. The switching circuit has high efficiency, generally up to about 80%, and the cost is also high.

For a light source composed of less than 8 low-power LED chips (standard 20mA), there are many commercially available DC/DC conversion chips that can be used as drivers, and many of them are constant current drivers. We can adjust the current from 5 to 40mA, and it also has a shutdown mode. The efficiency can reach 85%.

For the case where the number of LEDs is relatively small, a constant voltage drive can also be used. The minimum input voltage only needs 0. 9V to start work. As the input voltage increases, its conversion efficiency also increases. Through reasonable selection of peripheral devices, the highest conversion efficiency is about 85%.

For the case of using ordinary commercial power as the power supply, the LED drive circuit is relatively more mature. The low-power LED light source can be driven by a capacitor step-down to achieve constant current. For high current conditions, a switching constant current drive circuit can be used, and the efficiency is high, up to 80%. The cost is also acceptable. Many manufacturers can develop power chips.