LED color rendering index related information

When we manufacture LED lights, there are many indicators that need to be gradually improved, such as life span, EMC, environmental protection, safety, reliability and color rendering index. Let us discuss the role of the color indicator together.

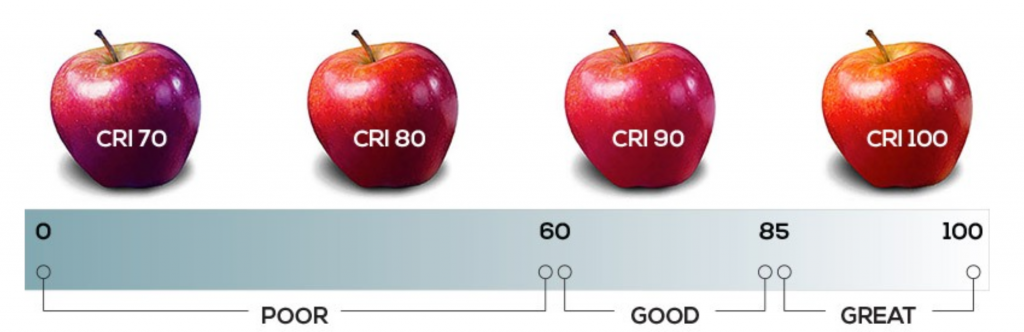

Color rendering index: Generally, the color of LED lights is different from that of sunlight. It is known that the white light of a fluorescent lamp is purple at first, and then it emits white or other colors after exciting the phosphor. Some color temperatures will be lower. Our indoor lighting is not sensitive to these, but it will be different on the road. A low color rendering index will cause visual errors, which will have a great impact on drivers who are driving. Resolving power will decrease, making the eyes feel tired.

When encountering these problems, what solutions should we look for?

At present, most packaging factories can produce products with high color rendering index. If it is to be used on the road, the requirements for the color rendering index will be higher, but the most important thing is the brightness requirement.

In order to solve these problems, on the one hand, the color rendering index of the product can be improved, and on the other hand, the light output efficiency of the product can be improved. The current brightness of the three primary colors or mask filters cannot be achieved, especially in fog and rain, which will cause many problems.

- Mercury lamps and sodium lamps have been used on the road for decades, but they do not reflect the problem of eye fatigue. In the era of formulating road lighting standards, the issue of energy conservation and environmental protection has not been realized. The road lighting standards developed should meet the requirements for clear road viewing, but the color rendering index is not taken into consideration. For road lighting, the color rendering index is not a big issue. Of course, a higher color rendering index makes it easier for people to distinguish objects, and you can appropriately consider reducing the brightness, which is more in line with today’s energy saving and environmental protection concepts. If there is a good one, why not?

- Low color rendering index is not necessarily the cause of eye fatigue, the main reason is brightness. The color rendering index of fluorescent lamps is not high, but it has been used for decades, and there is no myopia caused by the low color rendering index of fluorescent lamps. If this happens, the production and sale of indoor light sources with a color rendering index lower than 75 should be immediately prohibited.

- The low color rendering index has little effect on daily life and learning. Except for color design occasions (such as painting exhibitions, color design, etc.), if the color rendering index is not high, the color you see will be different from the color that appears under the sun. If the brightness is sufficient, it will not cause eye fatigue. Even in the outdoors, the color rendering is not exactly the same in the morning, noon and afternoon of the day. Similarly, it is of course the best to be able to use a light source with a high color rendering index for illumination. For example, when you buy clothes, you need a color. If you look good in a certain light, you can view it in other light or outdoors, and you will find that something is wrong. This happened when fluorescent lamps replaced incandescent lamps, and people often took clothes and cloth outside in shopping malls to check the color.

- Don’t exaggerate the color rendering index. Objective evaluation should be made. (never talk about it with commercial purpose)

- Several methods have been proposed on the market to improve the color rendering index of white LEDs used for lighting. Here I want to talk about my opinion:

(1) Add color compensation to existing LED products. One is to add different phosphors, which is mostly done in the packaging industry. The other is to add additional colored LEDs. Due to the limited spectrum options of color LEDs, this method can be improved appropriately but not very well.

(2) Three primary colors LED white light. The color rendering index is very low. In order to increase the color rendering index, we also need to add other spectrum LEDs. Limited by the current LED spectrum, the color rendering index is difficult to reach 85. The cost of such a lamp is too high and has no practical significance.

(3) Use a mask to filter colors. This method can be adjusted to a higher color rendering index, but the light loss is very large, so this is of no practical significance.

High CRI LED Lighting Solution

With the continuous development of LED technology, it is possible for led to be used as lighting source. Due to the strict requirements of color rendering index CRI for light source in lighting lamps and lanterns, the current white LED technology is not mature in color rendering, which makes it the main obstacle to restrict LED as lighting source.

White light is a compound light. It is easy to decompose the light of various colors contained in the white light through a prism. LED is a kind of light source with more comprehensive spectrum, which lays a theoretical foundation for high color rendering of LED lighting products.

Light is a kind of material with wave particle duality, which contains the characteristics of wave and particle, which makes it have strong composite characteristics. Therefore, from the nature of light and the characteristics of LED, it is possible to make LED become a high-quality lighting source.

At present, the white LED technology mainly uses a phosphor manufacturing process coated with blue chips. This technology was developed by Riya, and it follows the luminescence principle of fluorescent lamps. Due to the lack of red and green light components, this technology has a congenital defect of insufficient color rendering index. At present, in order to make up for this defect, phosphor technology has become the main research direction in industry.

Blue chip coated with phosphor to produce white light technology, this technology can produce better white light in principle, but in the process of use, due to the weak adaptability to the environment, the difference between theoretical and practical products is largely due to the influence of LED thermal accumulation temperature on phosphor.

We all have such experience, as the working time goes on, the heat generation and heat loss gradually reach a balance state. The higher the temperature of this equilibrium state is, the greater the impact on white LED with the same type of phosphor is. With the continuous rise of LED temperature, the activity of phosphor will be greatly reduced (the conversion formula of Fahrenheit / centigrade is: centigrade = 5 / 9 * (Fahrenheit – 32). The activity of phosphor is better at 100 degrees Fahrenheit, but the activity of phosphor is almost lost at about 250 degrees Fahrenheit (120 degrees Celsius).

With the rise of LED temperature, the activity of phosphor is gradually inactivated, at the same time, the wavelength of the light emitted by the phosphor also shifts, which is red shift, that is, the emission wavelength of phosphor shifts to the red wavelength; This phenomenon seems to indicate that with the increase of temperature, the color rendering of white LED should be better, but actually it is reduced. It seems to be a contradictory problem. The essence of this phenomenon is that the offset of phosphor to red wavelength is less than the inactivation of phosphor, that is, the red light excited by phosphor in high temperature state is not enough to make up for the loss of red light caused by mixing, so it shows temperature The color rendering index of white LED decreases with the increase of temperature.

As the temperature of the LED increases, while the activity of the phosphor gradually decreases, the wavelength of the light emitted by the phosphor also shifts, that is, a red shift, that is, the emission wavelength of the phosphor shifts to a red wavelength. This phenomenon seems to indicate that as the temperature increases, the color rendering of white LEDs should be better, but in fact it will decrease. This seems to be a contradictory issue. The essence of this phenomenon is that the shift of the phosphor to the red wavelength is less than the inactivation of the phosphor. That is to say, the red light excited by the phosphor at high temperature is not enough to compensate for the red light loss caused by mixing, so it appears as the temperature increases. The color rendering index of the LED decreases, which is consistent with the decrease of the white light LED color rendering index with the increase of temperature.

From the above analysis, it can be concluded that the first way to improve the color rendering index of white LED is to reduce the LED temperature, and the second is to improve the adaptability of phosphors to high temperature. The third is to use color compensation technology, using red or amber led to compensate the color rendering index.

In terms of reducing LED temperature saving, the most effective means is to design LED packaging with high heat dissipation performance, which is one of the directions for China’s LED industry to make significant progress in LED intellectual property rights in the near future. As LED is a kind of low-voltage electronic product, the electrical safety requirements are relatively relaxed, so there are more heat-conducting substrate materials that can be used, and our industry is currently researching on this There are few studies, resulting in repeated violations of foreign intellectual property disputes.

Color compensation technology is a kind of technical means to make up for the loss of color LED color rendering index. This technical means is feasible in principle, but in practical application, it is faced with the strict restriction of mixed light conditions, so the practical application value is not high.

White light is in accordance with the mixed light theory of red, green and blue 3:6:1. This theory is based on our view of luminous objects. This mixed light technology can be successfully applied to the white balance technology of LED display screen. However, when applied to the lighting scheme, the mixed light scheme has little reference. This is because the human eye has an average characteristic and a habit of visible light Point, and these two characteristics, but also we unknowingly in the damage of vision important reasons.

The mixing technology of red, green and blue LED is a mature white lighting technology. Due to the large distance between different LEDs, the mixing distance is far. Adding a mixing cover in front of the LED can solve the problem of mixed light, but the light loss is also an obstacle, which hinders the development of light and thin lighting. Moreover, when people look directly at the lighting lamps and lanterns, it is not uniform white light; these two factors directly restrict the development of this technology.