Illuminance and Color Temperature

Illuminance and color temperature are two elements that constitute the lighting environment. The illuminance reflects the brightness and darkness of the environment. And the color temperature reflects the coldness and warmth of the light color.

Studies have shown that they will all have an impact on people’s mood and physical health. The poor combination of illuminance and color temperature will not only make people tired and reduce work efficiency. But also make people sick to varying degrees.

The Kruithof curve gives the best combination of illuminance and color temperature, which can be described as a combination of high illuminance and high color temperature, and a combination of low illuminance and low color temperature. Working under the same kind of light environment for a long time is also easy to make people tired. Therefore, office lighting requires dimming and color adjustment to establish a dynamically variable light environment.

Dual Channel Dimming and Color Adjustment

Among the many dimming and color adjustment methods, dual-channel dimming and color adjustment are more convenient and practical. Through experiments and theoretical calculations, engineers studied the changes in the color temperature and color rendering index of the mixed light after mixing white LEDs with different color temperatures and color rendering indexes. Steve Edwards gave the mapping relationship between correlated color temperature and duty cycle of the two channels. Nigel established a quantitative calculation model between the expected luminous flux, color coordinates and duty cycle of the two channels of mixed light.

Paul Nelson obtained the relationship between the ratio of the driving current of the two color temperature LEDs and the mixed color temperature. Peter Watson derives the calculation process of the color rendering index Ra of the mixed light source based on the spectral power distribution of white light LEDs with different color temperatures and the modulation pulse duty ratio.

Since two duty cycles are required to adjust the color temperature, they are slightly inconvenient in practical applications. Antonio Charles gave a solution for dimming and color adjustment using 2 equal periods and complementary PWM signals. However, the mapping relationship between the duty cycle and the light color measurement is not established, and the light color measurement cannot be quantitatively controlled. Since the two signals have equal periods and are complementary, one duty cycle can determine the relationship between color temperature and luminous flux.

Principle of Dual-channel Single Duty Cycle PWM Dimming and Color Adjustment

Dimming is the basis of toning. The essence of color temperature adjustment is to change the color temperature by adjusting the ratio of the luminosity of cold and warm light sources. LED adopts PWM dimming, and its luminous flux has a linear relationship with duty cycle. Compared with traditional light sources, it is easier to adjust the ratio of the luminous flux of cold and warm light sources, and the illuminance and color temperature can be accurately controlled.

(1) Principle of dimming

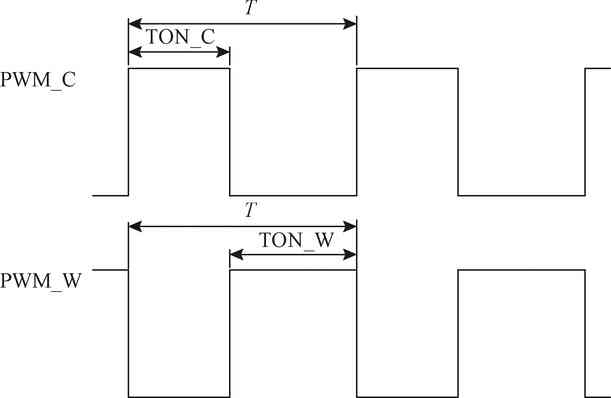

Dual-channel LED single-duty cycle dimming and color adjustment is a method for cold and warm LED light sources to perform dimming and color adjustment under two equal periods and complementary PWM signals. Complementarity here means that the high level time of the cold light source dimming signal PWM_C is equal to the low level time of the warm light source dimming signal PWM_W. Complementary PWM signals of the same phase are shown in Figure 1. From the perspective of the dimming effect, the two signals with different phases satisfying the above relationship are also complementary. As shown in equation (1), the sum of the duty ratios of these two signals is 1.

Fig.1 Complementary PWM signals in the same phase

Dc+Dw=1 (1)

Dc and Dw are the dimming duty cycles of cold and warm white LEDs, respectively. Suppose the maximum luminous flux of cold and warm white LEDs are Φc and Φw. If the cool white and warm white light sources are dimmed under the PWM signal of equal period, the mixed luminous flux Φm can be expressed as

ΦcDc+ΦwDw=Φm (2)

When Dc + Dw = 1, and the luminous flux of the cold and warm light source Φc and Φw are very close or equal, the mixed luminous flux Φm is almost unchanged. At this time, another PWM signal with a duty cycle of Dl is introduced to adjust the luminous flux after the color mixing. In this way, the mixed luminous flux can be calculated by formula (3).

Φm=(ΦwDw+ΦcDc)×Dl (3)

(2) Principle of toning

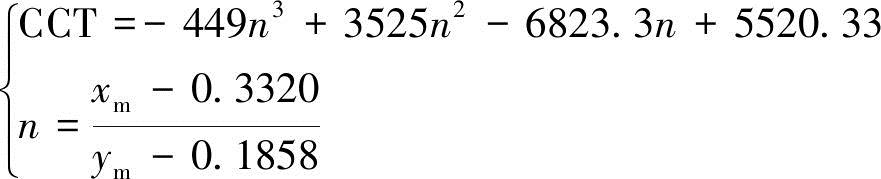

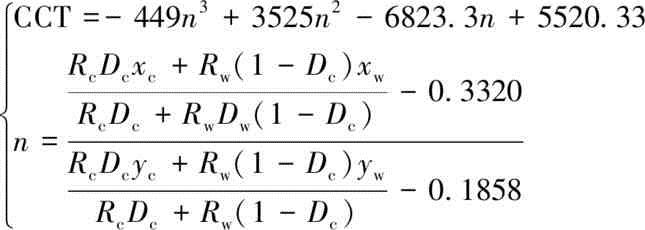

The adjustment of light color is achieved by adjusting the ratio of the luminosity emitted by the cold and warm light sources. The mixed color temperature can be obtained from the color coordinates after color mixing. For the LED light source, the correlated color temperature (CCT) is calculated by formula (4).

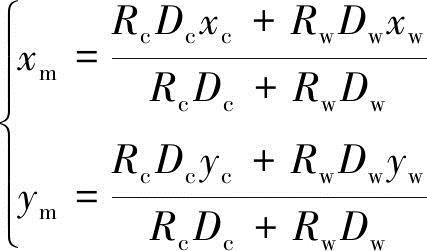

Where n is the reverse slope, (xm, ym) is the color coordinate of the mixed color. According to the light color superposition principle and the CIE1931 color coordinate calculation method, the mixed color coordinate can be calculated by formula (5). (5)

(5)

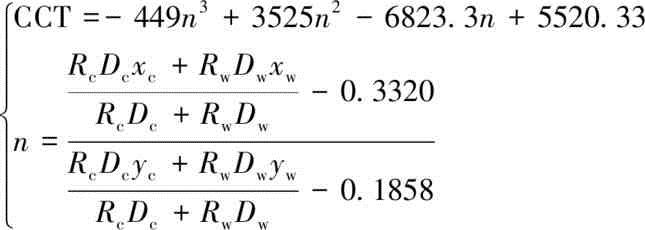

Among them, (xc, yc) is the color coordinate of the cool white LED, (xw, yw) is the color coordinate of the warm white LED, Dc is the dimming duty cycle of the cool white light source, and Dw is the dimming duty cycle of the warm white light source. Rc=Φc / yc, Rw=Φw/yw. Substituting the color coordinates of the mixed color of the formula (5) into the formula (4), the mapping relationship between the correlated color temperature and the duty ratios Dc and Dw can be obtained through the formula (6). (6)

(6)

Taking into account the constraint condition Dc+Dw=1, the mapping relationship between correlated color temperature and duty cycle Dc can be obtained by formula (7). (7)

(7)

Theoretical Analysis and Comparison

Using light source parameters (as shown in Table 1), according to the relationship obtained above, the dual duty cycle and single duty cycle conditions of the dual-channel dimming and color adjustment were analyzed and compared.

Table 1 Light source parameters

| Light source | (x ,y) | CCT / K | Luminous flux |

| Cool White | (0.303 4, 0.297 7) | 7500 | 323.86 |

| Warm White | (0.491 8, 0.425 2 ) | 2500 | 282.76 |

(1) Analysis and comparison of feasible regions

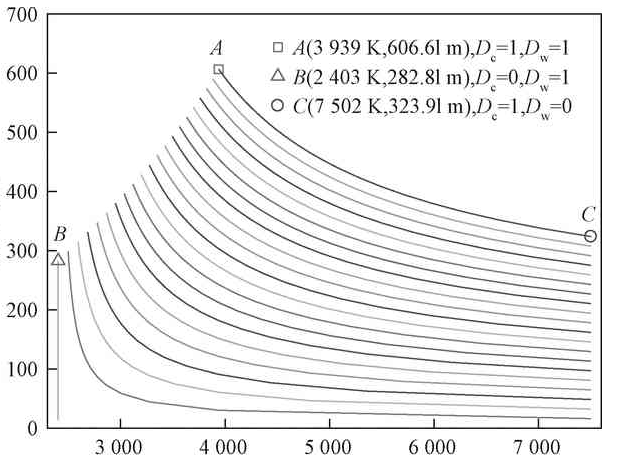

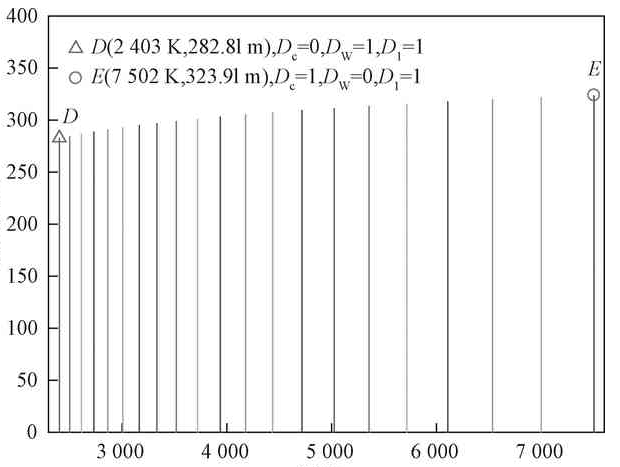

The theoretical feasible range of the dual duty cycle correlated color temperature and luminous flux is obtained by formula (2) and formula (6) (Figure 2). Through formula (1), formula (2) and formula (7), the theoretical feasible range of single duty cycle correlated color temperature and luminous flux is obtained (Figure 3). It can be seen from Figure 2 and Figure 3 that the feasible range of correlated color temperature and luminous flux is actually filled by a series of curves. The duty cycle Dc increases from 0 to 1 with the curve position from left to right. The minimum value of the mixed luminous flux is the same, and the mixed color temperature is between the highest color temperature and the lowest color temperature.

The maximum mixed luminous flux obtained by the dual duty cycle is the sum of the maximum luminous flux of the cold and warm light sources. The Dc and Dw corresponding to point A on the boundary curve AC in Fig. 2 are both 1, and the mixed luminous flux is the largest. The maximum luminous flux obtained with a single duty cycle is the larger value of the luminous flux of the cold and warm light sources, as shown in Figure 3 for the luminous flux corresponding to point E.

Fig.2 CCT range with dual duty cycle

Fig.3 CCT range with single duty cycle

(2) The relationship between mixed luminous flux and duty cycle

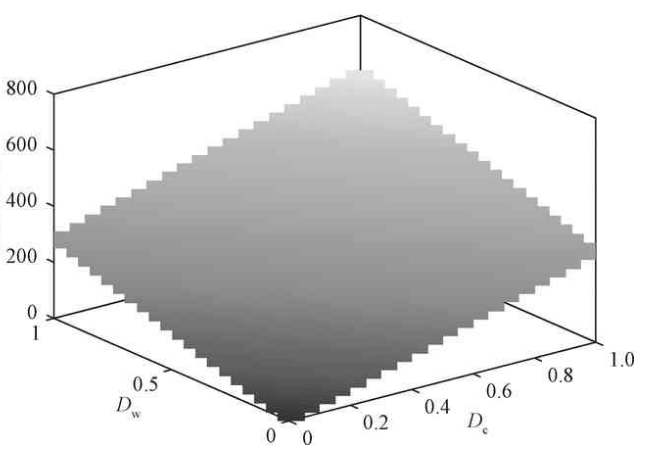

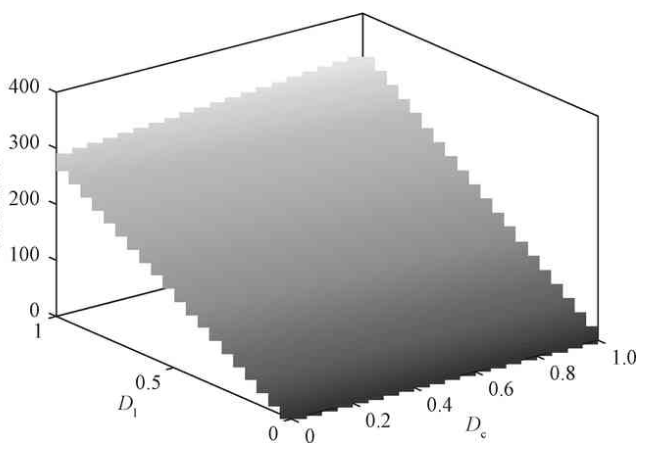

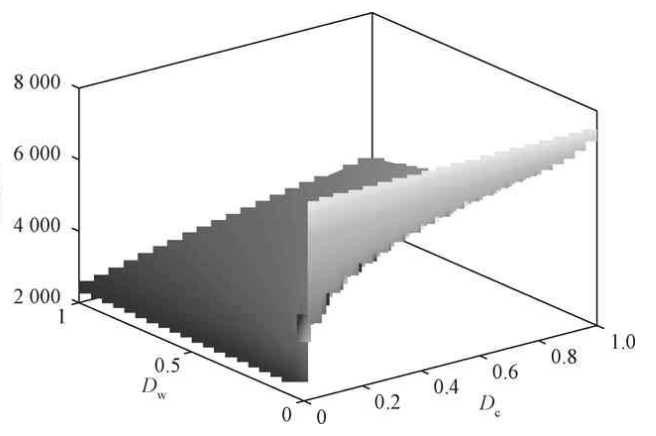

Fig. 4 is obtained according to formula (2), and Fig. 5 is obtained according to formula (1) and formula (3). It can be seen from Figure 4 that when dual duty cycle dimming and color adjustment, Dc and Dw are independently taken from the interval [0, 1], and the two together determine the mixed luminous flux Φm. It can be seen from Figure 5 that when the luminous fluxes of the cold and warm light sources are almost equal. The duty cycle Dc has almost no effect on the mixed luminous flux. The luminous flux can only be controlled by a duty cycle D1 dedicated to dimming.

Fig.4 Relationship between dual duty cycle and luminous flux

Fig.5 Relationship between single duty cycle and luminous flux

Although the luminous flux obtained by the dual duty cycle is greater than that of the single duty cycle, the advantage of using single duty cycle dimming and color adjustment is that the light measurement can be kept basically unchanged during the color adjustment process. This is very convenient for lighting adjustment. The lack of maximum luminous flux can be compensated by increasing the power of the light source.

(3) The relationship between mixed color temperature and duty cycle

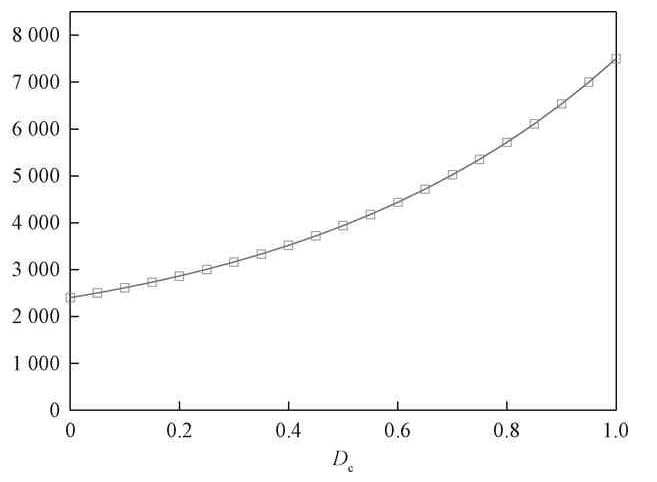

The determination of the relationship between correlated color temperature and duty cycle has guiding significance for dimming and color matching. From equation (6), the corresponding graph of dual duty cycle and correlated color temperature is obtained (Figure 6). From equation (7), the corresponding graph of single duty cycle and correlated color temperature is obtained (Figure 7). The mixed color temperature is between the cold/warm color temperature of the light source. Given the luminosity of cold and warm light sources, dual duty cycles adjust the color temperature. The duty cycles Dc and Dw are independently taken from the [0,1] interval, and the two jointly determine the mixed color temperature. Single duty cycle adjusts the color temperature. And the mixed color temperature is only a function of Dc, which increases with the increase of Dc.

Fig.6 Relationship between dual duty cycle and CCT

Fig.7 Relationship between duty cycle Dc and CCT

Conclusion

We deduced the mapping relationship between duty cycle and light color metric in the single duty cycle color temperature adjustment method in the case of complementary PWM signals. Two white light sources with different color temperatures of 2,500 K and 7,500 K are used. And the theoretical calculation and analysis are carried out according to the dual duty cycle method and the single duty cycle method respectively.

The results show that the mixed color temperature of the two is between the cold/warm color temperature of the light source. When the single duty cycle method is used, the color temperature is only controlled by the duty cycle Dc. When the luminous flux of the cold and warm light sources are almost equal, the luminous flux can only be controlled by a duty cycle Dl specially used for dimming. And the duty cycle Dc has almost no effect on the mixed luminous flux.

The advantage of the single duty cycle dimming and toning method is that it can keep the luminous flux basically unchanged during the toning process. And the lack of its maximum luminous flux can be compensated by increasing the power of the light source.