What is COB?

COB light source is a high-efficiency integrated surface light source technology that directly attaches LED chips to a

mirror metal substrate with high reflectivity. This technology eliminates the concept of brackets, no electroplating, no reflow soldering, and no mounting processes, so the process is reduced by nearly three points For one, the cost is also saved by a third. The COB light source can be simply understood as a high-power integrated surface light source, and the light emitting area and dimensions of the light source can be designed according to the product shape and structure.

Features of COB light source

- Cheap and convenient.

- Electrical stability, scientific and reasonable circuit design, optical design, and heat dissipation design,

- Using heat sink technology to ensure that the LED has an industry-leading heat lumen maintenance rate (95%),

- Facilitate the secondary optical matching of the product, improve the lighting quality,

- High color rendering, uniform luminescence, no spot, healthy and environmentally friendly,

- Simple installation, convenient use, reduce the difficulty of lamp design, save lamp processing and subsequent

maintenance costs.

The main form of COB beads

There are two main forms of bare chip technology: one is COB technology, and the other is flip chip technology (Flip Chip). Chip-on-board packaging (COB), semiconductor chips are hand-attached and mounted on a printed circuit board, and the electrical connection between the chip and the substrate is realized by wire stitching and covered with resin to ensure reliability.

COB beads production process

The COB (Chip On Board, COB) process is first to cover the silicon chip placement point with a thermally conductive epoxy resin (generally silver-doped epoxy resin) on the substrate surface, and then place the silicon chip directly on the substrate surface. Heat treatment until the silicon wafer is firmly fixed on the substrate, and then wire bonding is used to directly establish an electrical connection between the silicon wafer and the substrate.

What is SMD

Brief Introduction

SMD LED means surface mount light emitting diode, SMD chip helps to improve production efficiency, as well as application in different facilities. It is a solid-state semiconductor device that can directly convert electricity into light. Its voltage is 1.9-3.2V, the red light and yellow light voltage are the lowest. The heart of the LED is a semiconductor chip. One end of the chip is attached to a bracket, one end is negative, and the other end is connected to the positive pole of the power supply, so that the entire chip is Encapsulated with epoxy resin.

The semiconductor wafer is composed of two parts, one part is a P-type semiconductor, in which holes dominate, and the other end is an N-type semiconductor, which is mainly electrons. But when these two semiconductors are connected, a P-N junction is formed between them. When the current acts on the chip through the wire, electrons will be pushed to the P area, where the electrons and holes recombine, and then emit energy in the form of photons. This is the principle of LED light emission. The wavelength of light is the color of light, which is determined by the material forming the P-N junction.

Main models of SMD

SMD LED 3528

3528 SMD lamp beads, power 0.06w, lumen value 6-7LM, 7-8LM, 8-9LM, luminous efficiency can reach up to 150LM/w.

SMD LED 2835

2835 SMD lamp beads, power 0.2w, lumen value 20-22LM, 22-24LM, 24-26LM, luminous efficiency can reach up to 130LM/w.

SMD LED 5050

5050 SMD lamp beads, power 0.2w, lumen value 20-22LM, 22-24LM, 24-26LM, luminous efficiency can reach up to 130LM/w.

SMD LED 5630

5630 SMD lamp beads, power 0.5w, lumen value 50-55LM, 55-60LM, luminous efficiency can reach up to 130LM/w.

SMD LED 3014

3014 SMD lamp beads, power 0.1w, lumen value 11-12LM, 12-13LM, luminous efficiency can reach up to 130LM/w.

SMD LED classification

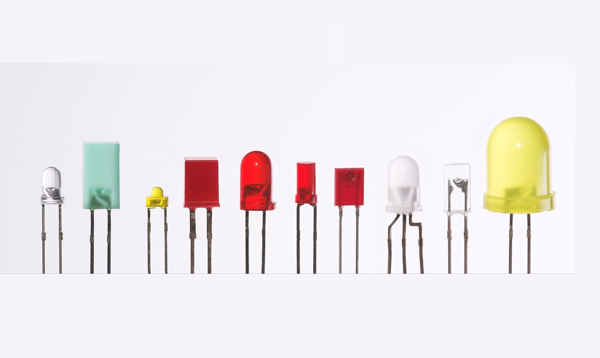

Commonly used LEDs are divided into four types: in-line LED, TOPLED, piranha and high power.

1) In-line LED:

The electrical connection is in the form of 2-pin in-line, which is a traditional, low-end product. Because the package has a large thermal resistance and the chip is not easy to dissipate heat, the light effect decays quickly and the life is short. The advantage is that it is cheap and can be made into a small light-emitting angle.

2) TOP LED:

The electrical connection is in the form of 2, 4 or 6-pin patch, which is currently the commonly used light source. According to the size of the package shape, it is divided into 0805, 1206, 3528, 3535, 5050, 5060 and other specifications. The larger the package shape, the better the heat dissipation performance, the correspondingly larger the bearable power, and the more light output.

3) Piranha:

It is a 4-pin in-line package. The heat dissipation performance and reliability are better than ordinary 2-pin in-line package. It can withstand a working current of 50~70mA. It is a commonly used light source.

4) High-power LED:

LEDs designed and produced with large-size chips and enhanced hot channel technology are usually divided into 0.5W\1W\3W\5W specifications. A single 1WLED can withstand a working current of more than 300mA and output a luminous flux of more than 100 lumens, which is widely used In civil commercial lighting, traffic control, photography, night vision and other fields. The price of high-power LEDs is still relatively high. With the gradual maturity of the technology, it will hopefully completely replace the traditional lighting sources and lead the world into an era of solid-state light sources.

The difference between SMD and COB

The full name of SMD is “Surface Mounted Devices”, which refers to surface mounted devices, which are one of surface mount technology components.

The full name of COB is “chip on board”, which refers to chip on board packaging and is one of the bare chip mounting technologies.

The light-emitting principle of COB and SMD is the same. The key lies in the contact area between the chip and the base. The plug-in is two-point contact, the patch smd is two-line contact, and the integrated cob is the entire surface contact. The other is the difference between the bracket and the cob. It is the whole bracket, and the lamp shell is directly equipped after the light source is packaged. After the smd package is completed, the lamp beads and the board must be attached. According to the production principle, cob heat dissipation is undoubtedly better.

The difference between SMD and COB is as follows:

- Different production efficiency

SMD: The production efficiency of SMD is low.

COB: COB has higher production efficiency than SMD.

- Different light quality

SMD: The combination of SMD’s discrete components has spotlight and glare.

COB: The viewing angle of COB is large and easy to adjust, there is no spot light, glare.

3. the process is different

SMD: The LED chip is fixed on the pad of the lamp bead holder with conductive glue and insulating glue, and then welded with the same conduction performance as the COB package. After the performance test, it is encapsulated with epoxy resin, and then split, Cutting and braiding, transportation to the screen factory and other processes.

COB: The LED chip is directly fixed on the soldering pad of the lamp bead on the PCB board with conductive glue and insulating glue, and then the conduction performance of the LED chip is welded. After the test is complete, it is encapsulated with epoxy resin.

4. different technologies

SMD: During the LED period, it needs to be mounted first, and then fixed on the PCB board by reflow soldering.

COB: Without mounting and reflow soldering process, COB light source is directly applied to lamps.

Advantages of COB package over traditional SMD package

With the continuous progress of solid-state lighting technology, cob (chip on board) packaging technology has been paid more and more attention. Because cob light source has the characteristics of low thermal resistance, high luminous flux density, less glare and uniform emission, it has been widely used in indoor and outdoor lighting, such as tube lamp, bulb lamp, fluorescent tube, street lamp and mining lamp.

This paper describes the advantages of cob packaging compared with traditional LED packaging, mainly from the production efficiency advantages, low thermal resistance advantages, light quality advantages, application advantages and cost advantages, and explains the leading position of cob packaging in the development of LED lighting field in the future.

- Manufacturing efficiency advantage

The production process of COB package is basically the same as the traditional SMD production process, and the efficiency of the solid crystal and welding line process is basically the same as that of SMD packaging. However, the efficiency of cob packaging is much higher than that of SMD products in dispensing, separation, light separation and packaging. The labor and manufacturing costs of traditional SMD packaging account for about 15% of the material cost, and the labor and manufacturing costs of cob packaging account for about 10% of the material cost %With COB package, labor and manufacturing costs can be saved by 5%.

- Low thermal resistance advantage

The system thermal resistance of traditional SMD packaging application is: chip – solid crystal glue – solder joint – solder paste – copper foil – insulating layer – aluminum material. The thermal resistance of cob packaging system is: chip – solid crystal glue – aluminum material. The system thermal resistance of COB package is much lower than that of traditional SMD package, which greatly improves the life of LED.

- Light quality advantage

The traditional SMD package pastes several discrete devices on the PCB to form the light source components for LED application. This method has the problems of spot light, glare and ghost. The COB package is an integrated package, which is a surface light source with large viewing angle and easy adjustment, which reduces the loss of light refraction.

- Application advantages (taking fluorescent tube cob as an example)

COB light source in the application side of the chip and reflow soldering process, greatly reducing the application cost of the production and manufacturing process, while the corresponding equipment can be omitted, the production and manufacturing equipment investment cost is lower, and the production efficiency is higher.

Taking the current manufacture of 1.2m 2000lm fluorescent tube as an example, it needs about 288pcs 3528 light source, the installation cost is about $0.01 / PCS, and the mounting cost of a 1.2m fluorescent tube is 288 * 0.01 = $2.88, which will be saved if COB light source is used.

Conclusion

With the more and more extensive application of LED in the field of lighting, from the perspective of cost and application, the integrated COB package is more suitable for the new generation of LED lighting structure. The development of COB package is the main way to solve the problems of high thermal resistance and high cost in the existing SMD packaging structure. The number of cob packages will gradually increase with its excellent performance in LED packaging, especially in the proportion of output value, which will further promote the popularity of LED lighting.