Why Do LEDs Generate Heat As A Cold Light Source?

1. What is cold light

First of all, to popularize what is a cold light source.

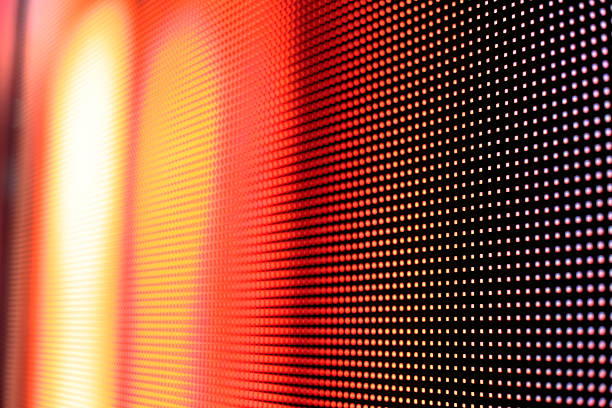

The so-called cold light source is a luminous light source with almost no infrared spectrum, which is different from a thermal light source with an infrared spectrum.

LED is a cold light source, and the light it emits is almost all visible light. Visible light has a wavelength of 380 to 780 nanometers.

Cold light sources are light-emitting light sources that contain almost no infrared spectrum. For example, the more popular LED light sources are typical cold light sources.

Traditional incandescent and halogen light sources are typical thermal light sources.

Cold light sources are light sources (fireflies, neon lights, etc.) that are excited by chemical energy, electrical energy, and biological energy.

It has a very good light source, variable flash characteristics.

When an object emits light, its temperature is not higher than the ambient temperature. This kind of light is called cold light. We call this type of light source a cold light source.

The cold light source has no heat, high brightness, consistent color temperature with the sunlight spectrum, high luminous efficiency/low energy consumption.

The light-emitting principle of the cold light source is that under the action of an electric field, electrons collide to excite the fluorescent material to produce light-emitting phenomenon.

The cold light source has very good optical and flickering characteristics.

The cold light source does not generate heat when working, avoiding a series of problems related to heat accumulation.

The characteristic of the cold light source is that almost all other energy is converted into visible light, and there is very little light of other wavelengths.

The thermal light source is different. In addition to visible light, there is a large amount of infrared light, and a considerable part of the energy is converted into infrared light that does not contribute to illumination.

The light emitted by the hot light source and the infrared filter should be similar to the light emitted by the cold light source, because the infrared light has been filtered out.

The light-emitting diodes that are being produced and the triodes that are being studied belong to one of the types of cold light sources. They all have the advantages of long life and soft lighting. They are a kind of light source that is expected to replace electric light bulbs.

Why doesn’t the LED light heat up?

Because the light emitted by the LED does not contain infrared rays.

We know that infrared rays conduct heat. Traditional light bulbs, such as Yuba lamps, conduct heat through infrared rays.

So you see, LEDs cannot transmit heat through infrared, but heat must be conducted, so an aluminum heat sink is added.

The design of the radiator is a major category of the LED lighting industry.

The electro-optical efficiency of LED can basically reach more than 90%, and this light-emitting process basically generates very little heat.

The light-emitting process of the thermal light source will reach a high temperature of several thousand K, and the tungsten wire can only emit light because of this high temperature.

2. Why do LEDs get hot

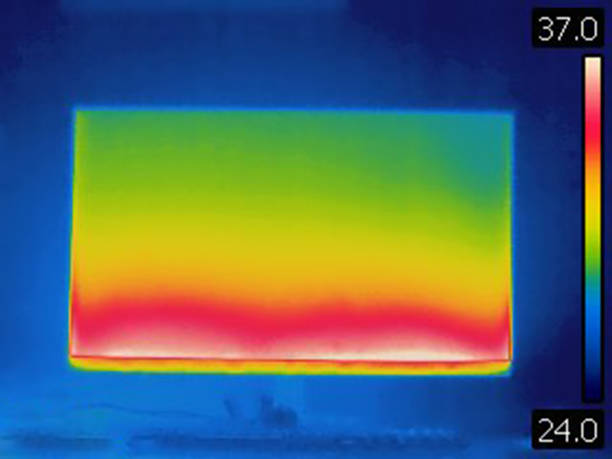

The heating of the LED lamp can be divided into two parts: the heating caused by the efficiency of the LED particles itself and the heating caused by the conversion efficiency of the LED drive circuit.

(1) LED particles generate heat

The power consumption of a single LED = the voltage drop of the LED tube * the current passing through and then combined with the luminous efficiency, the remaining power consumption is basically dissipated by heat and the like.

(2) LED drive circuit heats up

All LEDs need a drive circuit, which converts 220V or other voltages into low-voltage constant-current drive through a circuit similar to a switching power supply.

As long as it is a switching power supply, there is a problem of conversion efficiency.

To make things intuitive, assume a cheap LED driver has only 50% conversion efficiency.

A 1W LED works under the rated load. Although the power provided by the drive circuit to the LED particles is 1W, it needs to obtain 2W of power from the input power supply, and the remaining 1W of power must be dissipated in the form of heat.

The cheaper the bulb, the lower the conversion efficiency of the driver under cost constraints, which may cause more serious heat generation. At the same time, due to the cost, it is impossible to design a good heat dissipation structure. Finally, a vicious circle will result in poor product quality and so on.

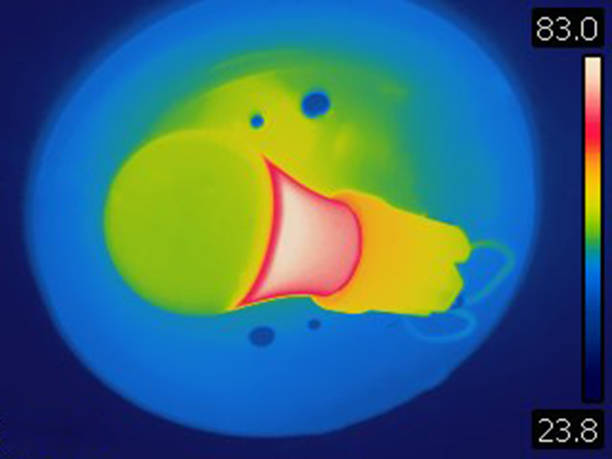

(3) Non-radiative recombination and driving current heating

Since the LED is essentially a diode, the electron-hole pairs at the PN junction recombine, and energy level transitions release energy. The excess energy of radiative recombination is released in the form of photons. Non-radiative recombination releases energy in other ways, such as heat.

The ratio of radiative recombination to the total recombination rate is the internal quantum efficiency.

The higher the internal quantum efficiency, the less heat is emitted.

And the LED chip needs to go through rectification, filtering, buck-boost, dimming and other circuits before it can be connected to the 220V voltage. These circuits are also the source of heat.

(4) The internal quantum efficiency is not high

That is to say, when electrons and holes are recombined, photons cannot be generated 100%, which is usually referred to as “electric vapor leakage”, which reduces the recombination rate of carriers in the PN region.

The leakage current multiplied by the voltage is the power of this part, which is converted into heat energy, but this part does not account for the main component, because the internal photon efficiency is now close to 90%.

(5) The photons generated inside cannot all be emitted to the outside of the wafer and finally converted into heat

This part is the main one, because at present this so-called external quantum efficiency is only about 30%, and most of it is condensed into heat.

Although the luminous efficiency of incandescent lamps is very low, only about 15lm/W, almost all the electrical energy has been converted into light energy and radiated out. Because most of the radiant energy is infrared, the light efficiency is very low, but the problem of heat dissipation is eliminated.

3. Sapphire LED

(1) Aluminum cooling fins

This is the most common way to dissipate heat. Aluminum fins are used as part of the housing to increase the heat dissipation area.

(2) Thermally conductive plastic shell

The use of LED insulating heat-dissipating plastics instead of aluminum alloys to make heat sinks can greatly improve the heat radiation capacity.

(3) Surface radiation treatment

The surface of the lamp housing is treated with radiation heat dissipation. The simple thing is to apply radiation heat dissipation paint, which can take the heat away from the surface of the lamp housing by radiation.

(4) Aerodynamics

Using the shape of the lamp housing to create convection air, which is the lowest cost way to enhance heat dissipation.

(5) Fan

The long-life and high-efficiency fan is used inside the lamp housing to enhance heat dissipation, with low cost and good effect.

However, it is more troublesome to replace the fan, and it is not suitable for outdoor use. This design is relatively rare.

(6) Heat pipe

Using heat pipe technology, the heat is conducted from the LED chip to the heat dissipation fins of the casing.

It is a common design in large lamps such as street lamps.

(7) Liquid bulb

Using the liquid bulb packaging technology, the transparent liquid with high thermal conductivity is filled into the bulb of the lamp body.

This is the only technology that utilizes the heat conduction and heat dissipation of the light-emitting surface of the LED chip in addition to the principle of reflection.

(8) Utilization of lamp caps

In household-type LED lamps with lower power, the inner space of the lamp holder is often used to partially or completely insert the heating drive circuit.

In this way, the lamp cap with a larger metal surface, such as a screw cap, can be used to dissipate heat, because the lamp cap is closely connected with the metal electrode of the lamp holder and the power cord. So part of the heat can be dissipated from this.

(9) Application of heat conduction and heat dissipation

The purpose of heat dissipation of the lamp housing is to reduce the working temperature of the LED chip. Since the coefficient of expansion of the LED chip is very different from that of our commonly used metal thermal conductivity and heat dissipation materials, the LED chip cannot be directly welded to avoid high and low temperature thermal stress damage the LED chip.

The latest high thermal conductivity ceramic material, the thermal conductivity is close to that of aluminum, and the expansion system can be adjusted to be synchronized with the LED chip. In this way, heat conduction and heat dissipation can be integrated, and the intermediate links of heat conduction can be reduced.

(10) PVC modified material

It has thermal conductivity and can be packaged twice.