Causes of LED light Decay

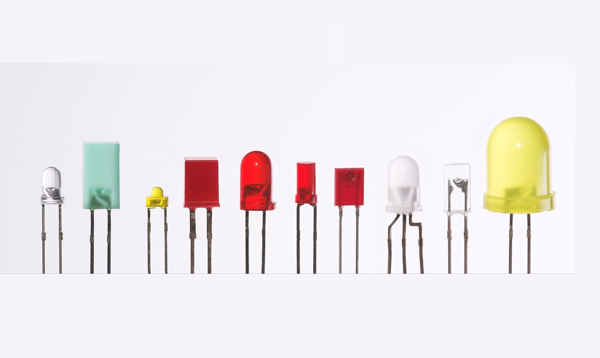

At present, the light decay of white LED in the market may be one of the most important problems in the development of civil lighting. There are two main factors for LED light decay:

first, the quality of LED products:

1) The quality of LED chips is not good, and the brightness decay is fast.

2) There are some defects in the production process. The heat dissipation of LED chip can not be led out from the pin pin pin, which leads to the high temperature of LED chip and the chip decay.

second, Use conditions:

1) LED is driven by constant current, and some LED is driven by voltage. The reason is that led is attenuated.

2) The driving current is greater than the rated driving condition. In fact, there are many reasons leading to LED product light decay, and the most critical problem is heat. Although many manufacturers do not pay special attention to heat dissipation in secondary products, the degree of light decay of these secondary LED products after long-term use will be higher than that of LED products which pay attention to heat dissipation. The thermal resistance of LED chip itself, the influence of silver glue, the heat dissipation effect of substrate, colloid and gold wire are also related to light decay.

Three factors that affect the quality of LED lamps.

The data detected by a single LED white lamp on the aging board are different from the data detected when the LED white lamp is assembled into a lamp when it is aging. The difference depends on the electrical parameters of LED and the design of lamps, as well as the environment in which the lamps are used.

First of all, choose what kind of LED white light.

This is very important. The quality of LED white light can be said to be a very important factor. For example, the same 14 mil white segment chip is used as a representative. The white LED lamp is packaged with ordinary epoxy resin primer, white light glue and packaging glue. When a single LED lamp is illuminated at 30 degrees, after 1000 hours, the decay data is 70%; if the LED is packaged with class D low-aging glue water, under the same aging environment, the 1000 hour decay rate is 45%; if the class C low-aging glue package is used, the light decay is 45% under the same aging environment, the 1000 hour aging rate is 12%; if the type B low aging glue is packaged, the 1000 hour aging rate is – 3%; if the class low aging glue is under the same aging environment, the 1000 hour aging rate is – 6%.

Why do different packaging processes cause huge differences?

One of the main reasons is that the LED chip is afraid of heat. Occasionally heating over 100 degrees for a short time is not important, but if used at high temperature for a long time, it will cause great damage to the LED chip. Generally speaking, the thermal conductivity of ordinary epoxy resin is very small, so when the LED chip is turned on, it will generate heat, while the thermal conductivity of ordinary epoxy resin is limited. Therefore, when the temperature of the LED bracket is measured at 45°C from the outside of the LED white lamp, the chip center temperature in the LED white lamp may exceed 80°C.

The temperature node of the LED is actually 80 degrees, so when the LED chip is working at an energy-saving temperature, it will be very painful, which will accelerate the aging of the white light of the LED. When the LED chip is working, the core temperature will produce a high temperature of 100 degrees. It can immediately conduct 98% of the heat through the bracket pin to reduce thermal damage to it. Therefore, when the temperature of the LED white light bracket is 60°C, its chip center temperature may only be 61°C. It can be seen from the above data that what kind of LED white light packaging technology directly determines the light decay of the LED lamp.

Secondly, the working environment temperature of LED lamp beads.

According to the aging data of a single white LED lamp, if only one white LED lamp is turned on and the ambient temperature is 30°C, the temperature of the bracket of a single white LED lamp will not exceed 45°C. At this time, the life span of this led will be ideal. If 100 white LED lights are turned on at the same time, and the interval between them is only 11.4mm, the temperature of the white LED lamp bracket around the bulb may not exceed 45 degrees, but the white LED light in the middle of the lamp stack may reach 65 degrees. Degrees of high temperature. This is a severe test for LED lamp beads.

Therefore, theoretically, the white LED lights in the middle will fade faster, while the decay of the white LED lights around the lamp holder will be slower. However, if the distance between the LED beads exceeds 25 mm, the heat they emit will not accumulate. At this time, the temperature of each LED white light bracket should be less than 50 degrees, which is more conducive to the normal operation of the LED.

If the working environment of the LED is in a relatively cold place, the annual average temperature may only be around 15 degrees or lower, which will have a longer service life for the LED. Or, when the LED is working, a small fan will blow the air to help it dissipate heat, which is also very helpful for the life of the LED. In any case, we should know that LEDs are afraid of heat. The higher the temperature, the shorter the life of the LED. The lower the temperature, the longer the LED life. The ideal operating temperature of the LED is between minus 5 and zero. But this is basically impossible. Therefore, after understanding the ideal working parameters of LED lamp beads, the functions of heat conduction and heat dissipation should be strengthened in lamp design.

Thirdly, the design of working electrical parameters of LED lamp beads.

According to experimental results, the smaller the drive current, the smaller the heat generation, and of course the smaller the brightness. According to surveys, in the design of LED solar lighting circuits, the LED drive current is generally only 5-10mA. For products with a large number of lamp beads, such as more than 500 or more, the drive current is usually only 10-15mA, which is generally popular. The driving current of LED application lighting is only 15-18mA, and few people design the current above 20mA.

The experimental results also show that when the internal air temperature reaches 71 degrees under the driving current of 14mA, the low light decay product will have zero light decay within 1000 hours and 3% within 2000 hours. This shows that in this environment, the low-light-decay LED white light has reached its maximum limit, and it will cause damage if it is too large.

Since the burn-in board used for burn-in has no heat dissipation function, the heat generated during the operation of the LED is basically unable to be conducted to the outside. Experiments have proved this. The air temperature on the aging board has reached 101°C, and the surface temperature of the cover on the aging board is only 53°C, a difference of tens of degrees. It can be seen that the designed plastic cover basically does not have the function of heat conduction and heat dissipation. However, the functions of heat conduction and heat dissipation are considered in the design of general lamps.

Therefore, the design of working electrical parameters of LED lamp beads should be determined according to actual conditions. If the heat conduction and heat dissipation function of the lamp is very good, the driving current of the white LED lamp will increase, which is not important, because the heat generated by the LED lamp bead can be instantly dissipated to the outside without damaging the LED. This is for the LED Best maintenance. On the contrary, if the heat conduction and heat dissipation function of the lamp is not good, it is best to design the circuit smaller and let it emit less heat.

Researchers believe that because the Ager effect is an internal formation mechanism, LED light decay cannot be eliminated, but it can be minimized. The editor of OFweek Semiconductor Lighting Network believes that since it can be minimized, what aspects should we start with? I believe this is also the concern of many netizens. Next, we will analyze the relationship between the light decay of the white LED and the chip, solid crystal primer, phosphor and other materials.

Relationship between light decay and materials of white LED

With the advent of blue LED, white LED can be easily obtained by the combination of phosphor and blue LED, which is the most mature way of white light packaging in the industry. With the advent of blue LED, white LED can be easily obtained by the combination of phosphor and blue LED, which is the most mature way of white light packaging in the industry. At present, white LED has become a lighting source, and general household lighting has become a reality. However, in the process of use, many white light products have great decay, which can not be suitable for the lighting market.

In view of the demand of high-end lighting market, Taiwan Hongcai optoelectronics has increased the research and development of white light, and developed low decay white light products by changing the packaging process and material mix, making a modest contribution to the LED lighting industry. The following are the five experiences we have summed up in the process of packaging. We would like to exchange views with colleagues in the industry, so as to contribute to the improvement of white LED packaging technology.

- The influence of chip on the light decay of white LED

According to the current experimental results, the influence of wafers on light decay can be divided into two categories: first, the different materials of wafers lead to different decay. At present, the commonly used substrates of blue light wafers are SiC and sapphire. The general structure of SiC is designed as a single electrode, which has better thermal conductivity. Sapphire is generally designed with double electrodes, which is difficult to derive heat and has poor thermal conductivity The second is the size of the wafer, which is different in size and decay difference when the chip material is the same. - The die-bonding glue commonly used in the white light LED packaging industry includes epoxy resin die-bonding glue, silicone resin insulating glue and silver glue. Each of the three has its own advantages and disadvantages and should be considered comprehensively. Epoxy resin insulating glue has poor thermal conductivity, but high brightness. The thermal conductivity of silicone insulating glue is slightly better than that of epoxy resin, and the brightness is high. However, due to the proportion of silicon components, the remaining silicone resin will be combined with the epoxy resin in the fluorescent glue during the solidification process, which will cause the barrier phenomenon after the thermal shock and cause the lamp to die. The thermal conductivity of silver glue is better than the first two, which can prolong the life of the LED chip, but the absorbance of silver glue is relatively large, resulting in lower brightness. For double-electrode blue wafers, when using silver glue to fix the crystal, the glue amount is also very strict, otherwise it is easy to produce a short circuit, which directly affects the yield of the product.

- The influence of phosphor on the light decay of white LED

There are many ways to realize white LED. At present, the most common and mature one is to coat a layer of yellow phosphor on the blue chip to mix the blue light and yellow light into white light, so the material of phosphor has a great influence on the decay of white LED. The most popular phosphors in the market are YAG yttrium aluminum garnet phosphor, silicate phosphor and nitride phosphor. Compared with blue LED chip, phosphor can accelerate the aging of white LED, and the influence degree of phosphor from different manufacturers is different, which is closely related to the raw material composition of phosphor. The best material white phosphor is selected by Leiman optoelectronics, which makes the white LED have a great improvement in decay control compared with peers.

- The influence of fluorescent glue on the light decay of white LED

In traditional packaging white LED, the fluorescent glue is usually epoxy resin or silica gel. The results of light aging experiment show that the life of white LED with silica gel powder is significantly longer than that of epoxy resin. One of the reasons is that the UV resistance of silica gel is stronger than that of epoxy resin, and the heat dissipation effect of silica gel is better than that of epoxy resin. However, under the same conditions, the initial brightness of silica gel powder is lower than that of epoxy resin. The main reason is that the refractive index of silica gel (1.3-1.4) is lower than that of epoxy resin (1.5), so the initial luminous efficiency is not as high as that of epoxy resin.

- The influence of bracket on the light decay of white LED

LED bracket mainly includes copper bracket and iron bracket. The copper bracket has good thermal conductivity and high price. However, the thermal conductivity and conductivity of the iron bracket are relatively poor, and it is easier to rust, but the price is cheap.

Most of the LEDs on the market use iron brackets. Different materials have different effects on the performance of LED, especially on the light decay. This is mainly due to the fact that the thermal conductivity of copper is much better than that of iron. The thermal conductivity of copper is 398w (m.k), while that of iron is only about 50W (m.k), which is only 1 / 8 of the former, and the thickness of electroplating layer of the bracket is also closely related. When choosing the bracket, we should pay attention to whether the cup size of the bracket matches with the light-emitting chip and the mold particles. The quality of the matching directly affects the optical effect of white LED, otherwise it is easy to cause asymmetric spot shape.