With the gradual development of science and technology, the progress of lighting technology is also changing with each passing day. Starting from the original lighting method such as firelight lighting, to the later lighting technology of incandescent lamps and fluorescent lamps, they have witnessed the development of lighting technology. There was a new type of lighting technology 30 years ago, which is LED lighting. As a new type of light source, it has great development advantages in the field of lighting. The global demand for light sources has been increasing with economic development, and the average annual light source energy consumption accounts for 14% of the total energy consumption. Therefore, as a high-efficiency energy-saving light source technology, LED technology has received extensive attention.

1. LED Light Introduction

LED lighting belongs to semiconductor lighting. Its working principle is to realize the conversion of electric energy and light energy with the help of PN junction. There are many advantages of this kind of lighting technology, and there are three main points in summary.

First, environmental protection and energy saving. As the most important feature, because there is no heat radiation during operation, even if the device fails, it can be recycled. Therefore, LED technology is a new type of green light source. It is foreseeable that in the near future, traditional lighting sources will be completely replaced by semiconductor lighting.

Second, it is durable and has a long life. Generally speaking, the lifespan of LED lighting used for illuminating light sources is in the range of 50,000 to 100,000 hours, which is much higher than that of incandescent lamps and other light sources.

Third, it can be used in a wider range. In addition to ordinary daily lighting, it can also be used in the field of special lighting and landscape lighting. It can also be connected to a computer to realize real-time control.

2. Problems in the Development of LED Technology

Since the emergence of LED technology, relatively rapid development has been achieved. The power is also relatively small at first, and gradually develops more and more. And high-power LED lighting has also begun to spread to daily lighting applications.

In the process of continuous development and gradual promotion of LED technology, LED lighting technology has also begun to expose some problems. Among them, the heat dissipation capacity and heat dissipation performance are more prominent. Although energy conservation and environmental protection are considered to be one of the main advantages of semiconductor lighting, because its photoelectric conversion rate is only 20%, other electrical energy is radiated to the outside world in the form of heat energy. Therefore, the solution to the heat dissipation and design problems of LED lighting fixtures has increasingly become a restrictive factor that affects the greater development of this technology.

In LED lamps, as the power increases, the designed packaging structure needs to be more complicated. Coupled with a smaller package volume, this will cause the temperature rise of the PN junction to be very obvious. If the heat dissipation level is not high at this time, it will cause the phenomenon of light attenuation of the light source.

The utilization technology of luminous efficiency has not achieved satisfactory development so far, and the level reached is only one-fifth. Other electric energy is not used effectively, but is lost as heat energy. This loss of heat will also destroy the LED luminous effect.

Relevant research data shows that in LED light source accidents, accidents caused by excessive temperature accounted for 70%. Therefore, the research on the heat dissipation and design of LED lamps is the focus of technical research in the field of LED lighting.

3. Research on the Heat Dissipation of LED Lights

Thermal coupling is a common problem in distributed LED chips. The uneven temperature distribution is caused by the uneven chip structure. The appearance of the thermocouple phenomenon will cause the local temperature to continue to rise, and then will cause the life of the entire LED light source system to shorten. Therefore, the weakening of the thermocouple phenomenon is the main means and an inevitable strategy to improve the life of the light source.

PN junction is the main factor for the increase in LED temperature. Encapsulation is a necessary step for LED lighting fixtures, which causes difficulty in measuring the temperature inside the chip. In order to be able to measure the temperature, the heat dissipation performance of the PN junction is generally evaluated by measuring the thermal resistance. Because the thermal resistance is inversely proportional to the heat dissipation performance of the chip, the effective measure to effectively reduce the PN junction temperature is to reduce the thermal resistance. Therefore, in order to describe the heat dissipation of the chip, analyzing the thermal resistance is a necessary means.

4. Research on the Heat Dissipation and Design of LED Lights

4.1 Thermal analysis of LED lamps

Because LED lamps have thermal coupling problems, it is unreasonable to use only power-type thermal field analysis for heat dissipation design. The heat dissipation path of the LED includes the transfer in the direction of the substrate as well as the transfer of the heat path along the transverse direction of the substrate. This shows that the circulation of heat also exists between the chips. Therefore, two aspects need to be considered when designing heat dissipation. One aspect is the heat sink structure that optimizes the heat transfer direction of the substrate. Another aspect is to optimize the chip layout for lateral heat transfer. In this way, the thermal resistance of the system can be effectively reduced, the temperature of the chip can be made uniform, the temperature of the chip junction can be reduced, and the service life of the lamp can be prolonged.

Average thermal resistance method and chip independent thermal resistance method

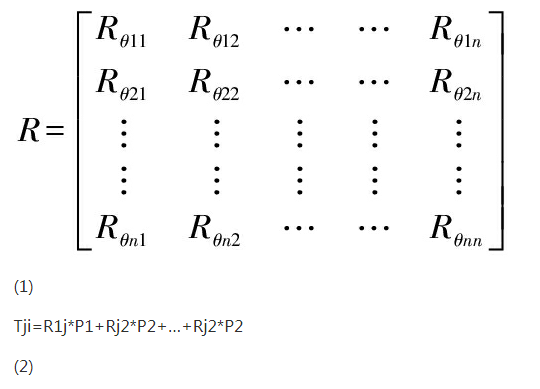

For the thermal resistance calculation of multiple heat sources, scholars have given two descriptions and solutions: the average thermal resistance method and the chip independent thermal resistance method. The average junction temperature of the appliance to the total energy consumption is the average thermal resistance, which is used to express the thermal resistance of multiple heat sources. Different from the average thermal resistance method, the energy consumption in the chip independent thermal resistance method is expressed by the energy consumption of each chip.

When the chip size and model are the same, and the coupled thermal field is not considered, the average thermal resistance method can be used. However, this method cannot be used when the junction temperature difference is large. The chip independent thermal resistance method does not apply to chips without power consumption, and thermal coupling is not taken into consideration. However, in actual situations, the effect of thermal coupling cannot be ignored. In order to overcome this shortcoming, a more reasonable thermal field analysis method, that is, the thermal resistance matrix method, is very effective in the thermal resistance analysis of multi-chip components.

First, the thermal resistance of a multi-chip LED lamp can be represented by the thermal resistance matrix of formula (1) according to the principle of linear superposition. For each chip, formula (2) can be used to express the junction temperature. Since the coupled thermal resistance will also affect the total thermal resistance of the lamp, the thermal resistance matrix will also be different due to changes in the matrix boundary conditions.

4.2 Establish a mathematical model of the component heat sink

The heat sink of LED lamps has two main parts: heat dissipation substrate and heat sink. They are closely connected. As shown in Figure 1, the heat conduction of the heat sink is carried out in three layers of medium: from the circuit layer to the insulating layer, and then to the metal layer. The function of each layer is different, but in general, the substrate is relatively thin, and the thickness to achieve the supporting effect has met the conditions of use. Therefore, the thickness of the substrate varies within a small range.

Although it is part of the overall thermal resistance of the system, the heat-dissipating substrate has a relatively small impact on the overall system. In addition, the variability is not high, so it can not be used as the main device that affects the heat sink. Relatively speaking, radiating fins are the main part of the radiator. The mathematical model of its temperature field can be expressed by the principle of heat conduction and the law of conservation of heat. The boundary of the radiating fins has less influence, because the thickness of the fins can be ignored relative to the height of the radiating fins.

Simply put, the increase in the heat dissipation area is conducive to the enhancement of the heat dissipation effect. But at the same time, the solid-state conduction thermal resistance will increase accordingly. Therefore, when designing LED lamps, the surface area of the radiating fins and the convective thermal resistance of the conduction thermal resistance must be considered at the same time, and then an optimized value can be obtained. Only in this way can we design high-quality LED lamps.

(To Be Continued)