High Intensity Discharge Lamp

Photoelectric characteristics of fluorescent high-pressure mercury lamps

Gas discharge lamps other than fluorescent lamps belong to the third generation of light sources. The mercury vapor pressure in the fluorescent lamp is extremely small, less than 1 Torr, so it is a low-pressure mercury lamp. The mercury vapor pressure of the currently discussed light source will be thousands of times or even higher than the mercury vapor pressure of fluorescent lamps, so it is called a high-pressure mercury lamp.

The light efficiency can reach 32~53Lm/w, and the life span is longer, generally over 5000h.

- Structure and light-emitting principle:

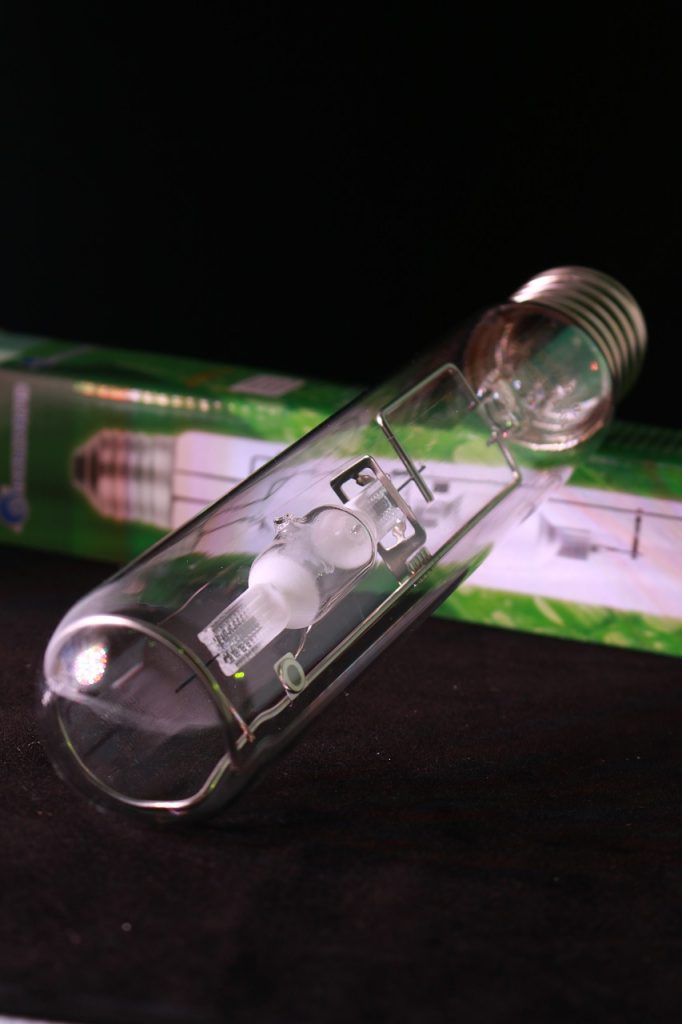

Structure: The core component of the high-pressure mercury lamp is the discharge tube. The discharge tube is made of high temperature resistant quartz glass. The tube is evacuated and filled with argon and mercury. Both ends are equipped with tungsten wire main electrodes. The electrodes are coated with metal oxides of barium, strontium, and calcium as electron emitting materials. One end of the tube is also equipped with an auxiliary electrode, which is very close to the electrode at the same end.

Luminescence principle: use the high pressure generated during mercury discharge to obtain high visible light luminous efficiency,

When the power is turned on, the electrodes at both ends are discharged, electrons and ions are generated, which triggers the discharge of the two main electrodes. But the initial discharge is only carried out in argon, which produces white light. As the discharge time increases, the temperature in the discharge tube continues to increase, and the pressure of mercury vapor gradually rises, so the discharge is gradually transferred to the mercury vapor, and the emitted light gradually changes from white to brighter blue-green.

- Start and restart of the high-pressure mercury lamp

After the lamp voltage is turned on, a glow discharge is generated between the main electrode and the auxiliary electrode immediately. Instantly, instantaneously, that is, transferred to the main electrode, forming an arc discharge. Due to the discharge heat, the mercury slowly discharges. After a few minutes, all of the mercury evaporates and reaches a steady state. The time to reach a steady state is called the start-up time.

When the fluorescent high-pressure mercury lamp is extinguished, it must wait until the tube is cooled and the mercury vapor pressure drops before it can be re-ignited. The re-ignition time is called the restart time, which is generally less than 10 minutes. If a high-pressure pulse is applied, it can be restarted even at high temperatures and high mercury vapor pressure. This is called a hot start.

Photoelectric characteristics of metal halide lamps

In the luminous tube, in addition to filling mercury and rare gases like fluorescent high-pressure mercury lamps, it is also filled with light-emitting metal halides (mainly iodides). Lamps that make luminescent metals into halides are called metal halide lamps;

The color rendering index of the metal halide lamp is relatively high, and its luminous efficiency can reach 100Lm/W under the condition of high power.

- Structure of metal halide lamp

The structure of the metal halide lamp is similar to that of the high-pressure mercury lamp. The luminous tube is made of quartz glass, and the glass bulb is designed to be miniaturized, which can increase the working temperature of the tube wall. In order to control the coldest temperature, the pipe end is coated with insulation film.

- The light-emitting principle of metal halide lamps

In the metal halide lamp, due to the large temperature difference between the tube wall and the arc center, the metal halide will undergo a cycle of decomposition and recombination. At the tube wall temperature, a large amount of metal halide evaporates and diffuses toward the center of the arc. In the high temperature zone at the center of the arc, the metal halide is decomposed into metal atoms and halogen atoms. Metal atoms participate in the discharge and generate radiation. When the metal atoms and halogen atoms in the central area of the arc diffuse toward the tube wall to the low temperature area, they recombine into metal halide molecules.

- Starting characteristics of metal halide lamps

Like other high-intensity gas discharge lamps, the start-up of metal halide lamps is divided into three basic stages: the first stage is the start-up gas (usually an inert gas, such as argon), from a non-conductive state to a conductive state, followed by The stage is cold cathode glow discharge and heating the electrode, and the final stage is thermionic arc discharge. A well-designed lamp is to make the glow discharge stage as short as possible, because the glow discharge causes the electrode material to sputter, covering the arc tube wall will cause the light output to decrease.

Compared with high-pressure mercury lamps, metal halide lamps require a much higher starting voltage. This can be attributed to the presence of iodides, especially mercury and hydroiodides, and the negatively charged iodide ions formed by the dissociated electron capture process.

- Luminosity and chromaticity characteristics of metal halide lamps

The composition classification of metal halide lamps: general lighting sources include dysprosium (Dy) lamps, scandium sodium (Sc-Na) lamps, sodium thallium (Nal-Tll-InI3) lamps, etc. The ultraviolet radiation of various metal halide lamps is weaker than that of indicator lamps, and the visible light radiation is more uniform, which not only has good color rendering, but also has high light efficiency.

Photoelectric characteristics of high pressure sodium lamp

The high-pressure sodium lamp is a high-strength gas discharge light source successfully developed in the early 1960s. It has the highest light efficiency in high-intensity gas discharge light sources. Because 589.0nm and 589.6nm sodium are in the region with the highest sensitivity of the human eye, the light efficiency can reach 100~120Lm/W. The longest life span can reach 18000~24000h. But its color temperature is low, generally 1600~2100K. The color rendering index is also low, generally 16~29, therefore, its use is limited.

- Luminescence principle of high pressure sodium lamp

When the high-pressure sodium lamp is started, the accessory and ballast generate a pulse voltage of 3KV to light the sodium lamp. At the beginning, the discharge is carried out by xenon and mercury. As the temperature in the discharge tube rises, the discharge of xenon and mercury transfers to the discharge of high-pressure sodium vapor, and the sodium vapor As the air pressure rises, the resonance radiation line of sodium is widened, and the light color is improved, and it tends to be stable in about 5 minutes, and it can emit a golden white light when working stably. When the working current and working voltage are stable at the rated value, the start-up process ends.

- Basic functions of high pressure sodium lamp

The working vapor pressure of the high pressure sodium lamp is 26.67kPa, the light color is golden yellow, the color temperature is 2100K, and the color rendering index is Ra=30, so the color rendering is poor, but the luminous efficiency is relatively high. The luminous efficiency of domestic high-pressure sodium lamps can reach 70~130lm/W. The high-pressure sodium lamp is characterized by its light efficiency close to low-pressure sodium lamp, light color is better than low-pressure sodium lamp, small size, high power, less ultraviolet radiation, and long life. It is an energy-saving electric light source, but the light color is yellowish and the fog penetration performance is good.

- Application of high pressure sodium lamp

Due to the high luminous efficiency, long life and good fog permeability, high pressure sodium lamps are widely used in high-rise factories, stations, squares, stadiums, especially urban roads and other places to illuminate commonly used high-pressure sodium lamps.

Problems that should be paid attention to when using high-pressure sodium lamps: fluctuations in the power supply voltage have a greater impact on the normal operation of the pair, and the increase in voltage will easily cause the lamp to extinguish itself; the decrease in voltage will reduce the luminous flux and the color of the light; the restart time of the lamp will be longer , Generally within 10-20min, so it cannot be used for emergency lighting or other places that need to be lit quickly; high-pressure sodium lamps should not be used in places that are frequently turned on and off, otherwise it will affect the service life.

Basic Theory of Commercial Lighting Design

With the improvement of people’s living standards, people have higher and higher requirements for shopping and consumption. In order to meet the needs of the people, it is necessary to have stores of various types and grades. The lighting of the store is no longer simply to illuminate the goods, but to form its unique commercial space lighting.

Commercial buildings and lighting

In recent years, commercial buildings in many cities have undergone a process of change from department stores to shopping centers, from a single-planar commercial shopping environment to a three-dimensional, comprehensive commercial building with comprehensive utilization of ground and underground spaces. The common characteristics of these commercial buildings with changeable patterns are their comprehensiveness, large scale and convenient shopping. Generally, the area is 30,000 to 60,000 square meters, and some have reached hundreds of thousands square meters, turning the commercial center into a colorful shopping world.

- Shopping psychology

In order to create a “place to purchase goods pleasantly and comfortably”, it is important to coordinate the composition and display of the store. The level and distribution of illuminance required by different commodities and different display methods, as well as the requirements for hue, color saturation, indoor color distribution, etc. vary greatly. It is necessary to adopt a variety of lighting forms, types of lamps, control methods, etc., and apply diversified methods.

In the design of modern commercial buildings, the owners and designers are ingenious and pursue high-level spatial style to meet the physical and psychological needs of shoppers. For example, on Broadway in New York, several tall green cedar trees and a magnificent musical fountain show an elegant style.

In the entire commercial building, in order to create a more interesting light environment in the shopping mall, fluorescent lamps and long-life energy-saving downlights are used in the selection of the ceiling light source of the shopping mall to produce a harmonious color vision. In terms of lighting methods, use hidden diffuser light troughs, light strips or other indirect methods to avoid strong stimulation as much as possible. In the layout of the lights, the product information can be transmitted to shoppers as soon as possible. Low light positions are often used. Some spotlights are used to cast light locally, directly on models or counters, so that customers can be quiet and relaxed. Appreciating the colorful products in the environment makes shopping a kind of enjoyment and leisure full of fun. This high-grade light environment will bring social and economic benefits to contemporary business.

- The role of lighting

In the fierce business war, the owners first asked the designer to work hard on the internal and external space of the commercial building to show their own style and emphasize their own individuality. Architects are deliberately constructing a fine art, and lighting design plays a unique role in rendering, highlighting and emphasizing the artistic personality of commercial buildings. Make the exhibits have a strong dramatic effect and vivid three-dimensional effect.

- Effective use of energy

In the operation of the store, the operating cost of the equipment accounts for a large proportion of the profit. The effective use of the total energy of the equipment including the lighting and the effective use of the lighting control system (switching, dimming) can be used for all stores. The effective use of energy. Preferably, the entire store can use an intelligent light control system.

In addition, through careful design, combining product characteristics and architectural treatment, using a variety of energy-saving light sources and lighting equipment, and adopting the lighting method of district general lighting supplemented by key projections, it can create a bright, comfortable, pleasant and pleasant shopping light environment for the store. Customers have a strong attractive business atmosphere, and lighting power consumption does not exceed energy-saving requirements.

Selection of light source and lamps

In commercial building lighting, in addition to the need for a certain illuminance, the light color and color rendering of the light source have a great impact on the atmosphere in the store, the color and texture of the goods, and so on. Bulbs can get directional light, while fluorescent lamps can get diffusive light. If these properties can be used well, more satisfactory commercial building lighting can be obtained.

- Types and characteristics of light sources

Many shops now use a combination of fluorescent lamps and compact energy-saving fluorescent lamps. In the future, the use of high-intensity gas discharge lamps with higher efficiency, better color rendering, and longer life, especially in large commercial buildings, will become more and more. 2. Light color (color temperature) and lighting

Depending on the light color (color temperature) of the light source, the image of the material can be set off. The light with high color temperature (greater than 5300K) should be illuminated with high illuminance (greater than 750Lx) to not only get a cool feeling, but also to get a strong and clear movement momentum. If the light of a high color temperature system is used in a place with low illumination (below 200Lx), it will become stuffy.

The color temperature between 3300~5300K is the intermediate color temperature, which is an intermediate effect between warm and cold.

- Color effects and lighting

There are two ways to display goods by the light source. One is to display the color of the illuminated object correctly; the other is to make the color look better. Generally, it is illuminated with a light with good color rendering, and the original color of the product is displayed, which is most suitable for the true display of colors and patterns of suits, fabrics, cosmetics, etc. It should also be noted here that in order to be able to distinguish colors correctly, a certain illuminance value is required. Even if the light source with high chromaticity is selected, the illuminance is only 100~200Lx, and the color vividness becomes weak. Generally, local lighting is used well, and at least the illuminance above 500Lx should be considered.