LED lighting has the advantages of safety, reliability, environmental protection, etc., and has been widely used in various fields of society, which is conducive to promoting social progress and improving people’s living standards. However, in order to meet the requirements of lighting quality and energy conservation, it is necessary to fully consider the problem of increasing the brightness of the lighting. At this stage, the brightness of LED lighting is mainly reflected in the insufficient application of scientific and technological means and the lack of brightness design solutions. It has not started to improve the efficiency of LED lighting equipment to ensure lighting quality. In particular, in the design of the lamp structure, there are still some LED lighting fixtures that are only considered from the internal component design, ignoring the influence of the lamp’s own structural characteristics on the lighting brightness, which is the main reason for the disadvantage of LED applications. Light-emitting diodes are a type of semiconductor device and have important applications in energy conservation and environmental protection. In order to give full play to the role of LED lighting, it is necessary to improve the brightness of the lighting, so as to provide people with a suitable lighting environment.

What is LED light

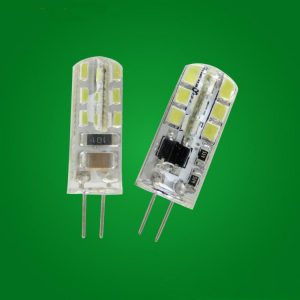

The LED lamp is a chip of electroluminescent semiconductor material. It is cured on the bracket with silver or white glue, and then the chip and the circuit board are connected with silver or gold wires. The periphery is sealed with epoxy to protect the inner core Role, and finally install the shell, so the shock resistance of LED lights is good.

The LED lamp is a chip of electroluminescent semiconductor material. It is cured on the bracket with silver or white glue, and then the chip and the circuit board are connected with silver or gold wires. The periphery is sealed with epoxy to protect the inner core Role, and finally install the shell, so the shock resistance of LED lights is good.

What causes the LED lights to dim

The dimming of LED lights is actually the light decay that we often say. The more the LED lights are used, the darker is because the LED lights will have a light decay phenomenon. Light attenuation is directly related to temperature, which is mainly determined by the chip, phosphor and packaging technology. Light decay is the main reason for the dimming of LED lights. The larger the light decay, the faster the LED darkens, and it will not light for a long time. The LED lamps are divided into three aspects: the driver, the chip and the beam. Low voltage is the main reason for dark.

The dimming of LED lights is actually the light decay that we often say. The more the LED lights are used, the darker is because the LED lights will have a light decay phenomenon. Light attenuation is directly related to temperature, which is mainly determined by the chip, phosphor and packaging technology. Light decay is the main reason for the dimming of LED lights. The larger the light decay, the faster the LED darkens, and it will not light for a long time. The LED lamps are divided into three aspects: the driver, the chip and the beam. Low voltage is the main reason for dark.

1. LED chip

Chip: The quality of the chip determines the electro-optical conversion efficiency and the main reason that affects the light efficiency. The chip is the light emitting body of the LED lamp, so when the chip is damaged, the brightness of the LED lamp will be weakened, which is what we call the darkening of the light, which will seriously cause the entire LED lamp to be off. The use of high-quality high-brightness chips reduces the light decay from the root, the emitted light is even and comfortable, more transparent and brighter, with a long service life and a three-year warranty.

2. Quality of LED phosphors

Phosphor: The quantum efficiency of the phosphor (intuitively expressed as brightness). The higher the quantum efficiency, the higher the light efficiency of the LED device. Increasing the quantum efficiency of phosphors will usually be accompanied by an increase in particle size. The increase in particle size will cause serious sedimentation, which makes the LED device dispensing process difficult to control, and the yield is low. Diameter and particle size distribution. The distribution of the phosphor in the silica gel has little effect on the light efficiency but has a more significant effect on the light quality. For example, when the COB product uses a centrifugal method, the phosphor is deposited on the chip. On the rice: the uniformity of the light is increased, but the phosphor the amount.

Phosphor: The quantum efficiency of the phosphor (intuitively expressed as brightness). The higher the quantum efficiency, the higher the light efficiency of the LED device. Increasing the quantum efficiency of phosphors will usually be accompanied by an increase in particle size. The increase in particle size will cause serious sedimentation, which makes the LED device dispensing process difficult to control, and the yield is low. Diameter and particle size distribution. The distribution of the phosphor in the silica gel has little effect on the light efficiency but has a more significant effect on the light quality. For example, when the COB product uses a centrifugal method, the phosphor is deposited on the chip. On the rice: the uniformity of the light is increased, but the phosphor the amount.

3. LED Packaging

Why do different packaging processes affect the brightness of LED lights? One of the main reasons is that LED chips are afraid of heat. Occasionally, if it is heated for more than a hundred degrees in a short period of time, it does not matter. If you are afraid of being exposed to high temperatures for a long time, it is a great damage to the LED chip. When the LED chip is damaged, the brightness of the LED light will be weakened. The lights will be dim or even off. For example, the data detected by a single white LED light on an aging board and the data detected when an LED white light is assembled into a lamp to age are definitely inconsistent. The magnitude of this difference depends on the electrical parameters of the LED during operation, the design of the luminaire, and the environment in which the luminaire is used. This is very important. The quality of LED white light can be said to be a very important factor. For example, the same is represented by the 14mil white light segment chip of the wafer, and the white LED light packaged with ordinary epoxy primer and white light glue and package glue is lit at 30 degrees. After one thousand hours, the attenuation data is 70% of the light attenuation :; if it is packaged with a low-grade D glue, the light decay is 45% in a thousand hours under the same aging environment; if it is packaged with a low-grade C glue, the same aging Under the environment, the 1000-hour light decay is 12%: if the B-type low decay glue is packaged, the 1000-hour light decay is -3% under the same aging environment; if the A-type low decay glue is, The hour light attenuation is -6%. So the quality of the packaging process determines the cause of the brightness of the LED lamp.

Why do different packaging processes affect the brightness of LED lights? One of the main reasons is that LED chips are afraid of heat. Occasionally, if it is heated for more than a hundred degrees in a short period of time, it does not matter. If you are afraid of being exposed to high temperatures for a long time, it is a great damage to the LED chip. When the LED chip is damaged, the brightness of the LED light will be weakened. The lights will be dim or even off. For example, the data detected by a single white LED light on an aging board and the data detected when an LED white light is assembled into a lamp to age are definitely inconsistent. The magnitude of this difference depends on the electrical parameters of the LED during operation, the design of the luminaire, and the environment in which the luminaire is used. This is very important. The quality of LED white light can be said to be a very important factor. For example, the same is represented by the 14mil white light segment chip of the wafer, and the white LED light packaged with ordinary epoxy primer and white light glue and package glue is lit at 30 degrees. After one thousand hours, the attenuation data is 70% of the light attenuation :; if it is packaged with a low-grade D glue, the light decay is 45% in a thousand hours under the same aging environment; if it is packaged with a low-grade C glue, the same aging Under the environment, the 1000-hour light decay is 12%: if the B-type low decay glue is packaged, the 1000-hour light decay is -3% under the same aging environment; if the A-type low decay glue is, The hour light attenuation is -6%. So the quality of the packaging process determines the cause of the brightness of the LED lamp.

Packaging Process Material-Silicone

Packaging Process Material-Silicone

The different light extraction rates of silica gel indirectly affect the light efficiency due to the different refractive index. The higher the refractive index, the higher the light extraction rate. In addition, the quality of similar gold wires, primers, and silver glues will affect the conductivity due to their effects on conductivity and thermal conductivity.

4. Bracket

The material of the bracket (such as copper, silver, iron, etc.) affects heat dissipation and indirectly affects chip performance and affects light efficiency: the material of the reflector cup (such as PPA, PCT, EMC, etc.), the flatness and thickness of the silver plated mirror bottom of the reflector cup affects light Extraction rate. It won’t light up when used, which is also due to the light decay caused by the material of the bracket. This not only makes the LED light emitting effect is not good, the light is very dark, the light decay time is shorter, and the degree is stronger.

5. LED lights are dim due to improper maintenance

The service life of LED lamps is not only related to the quality of the lamps, but also to the maintenance of the lamps. The dust behind the LED lamps should be cleaned with a dry cloth or a ladle.

How to make LED lights brighter

1. Power current changes brightness

The brightness of the LED light-emitting tube is related to the voltage directly applied to it. The higher the voltage, the greater the current flowing. The higher the brightness, the first requirement of the power supply is high efficiency, high efficiency products, and low heat generation. Stability is bound to be high. However, exceeding the rating will shorten the service life or even burn out. The brightness of the LED light depends on the operating current. The larger the current, the higher the brightness, but each LED has a rated operating current. For example, the working current of ordinary white small LED is about 25MA. If the current exceeds the rated value, it may lead to premature aging or damage of the LED. Each color of the LED lamp requires a voltage. If you want to increase the brightness, do not increase the voltage. This is not a problem. After the voltage is applied, the specified voltage (for example, 3v) will definitely burn out. Brightness must be increased through scientific principles. Brightness is calculated by power. The more power you need, the more power you have. The higher the power, the higher the brightness and the lower the power. High power and high brightness.

The brightness of the LED light-emitting tube is related to the voltage directly applied to it. The higher the voltage, the greater the current flowing. The higher the brightness, the first requirement of the power supply is high efficiency, high efficiency products, and low heat generation. Stability is bound to be high. However, exceeding the rating will shorten the service life or even burn out. The brightness of the LED light depends on the operating current. The larger the current, the higher the brightness, but each LED has a rated operating current. For example, the working current of ordinary white small LED is about 25MA. If the current exceeds the rated value, it may lead to premature aging or damage of the LED. Each color of the LED lamp requires a voltage. If you want to increase the brightness, do not increase the voltage. This is not a problem. After the voltage is applied, the specified voltage (for example, 3v) will definitely burn out. Brightness must be increased through scientific principles. Brightness is calculated by power. The more power you need, the more power you have. The higher the power, the higher the brightness and the lower the power. High power and high brightness.

2. Constant current drive

If you want to increase the brightness of the LED lamp, you can change the brightness of the LED lamp by adjusting the resistance of the current sampling resistor in the driving circuit. The brightness of the LED lamp can be changed by adjusting the resistance value of the resistor connected to the CS pin of the constant current drive device HV9910 as a current sampling resistor. Generally, reducing the resistance value of the resistor appropriately can improve the brightness of the LED lamp. On the contrary, increasing the resistance value can reduce the brightness of the LED lamp.

If you want to increase the brightness of the LED lamp, you can change the brightness of the LED lamp by adjusting the resistance of the current sampling resistor in the driving circuit. The brightness of the LED lamp can be changed by adjusting the resistance value of the resistor connected to the CS pin of the constant current drive device HV9910 as a current sampling resistor. Generally, reducing the resistance value of the resistor appropriately can improve the brightness of the LED lamp. On the contrary, increasing the resistance value can reduce the brightness of the LED lamp.

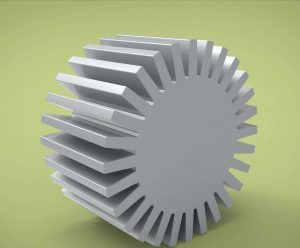

3. The heat changes the brightness

Whether the LED brightness and work is stable and the quality is good, it is very important to dissipate heat from the lamp body itself. Thermal management is a major problem in high-brightness LED applications. Because the p-type doping of III-nitrides is limited by the solubility of the Mg acceptor and the higher activation energy of the holes, heat is particularly easy in the lifetime of high-brightness LEDs in the p-type region. Fatal problem with heat dissipation. Generally speaking, whether the LED lamp works stably and with good quality is very important for the heat dissipation of the lamp body itself. At present, the heat dissipation of high-brightness LED lamps on the market often uses natural heat dissipation, and the effect is not ideal. The heat dissipation path of LED devices is mainly heat conduction and convection. The extremely low thermal conductivity of the Sapphire substrate material increases the thermal resistance of the device, produces a serious self-heating effect, and has a devastating effect on the performance and reliability of the device. The effect of heat on high-brightness LEDs. The heat is concentrated in a chip with a small size, and the temperature of the chip rises, causing non-uniform distribution of thermal stress, the chip’s luminous efficiency, and the efficiency of the phosphor lasing. When the temperature exceeds a certain value, Device failure rate increases exponentially.

Whether the LED brightness and work is stable and the quality is good, it is very important to dissipate heat from the lamp body itself. Thermal management is a major problem in high-brightness LED applications. Because the p-type doping of III-nitrides is limited by the solubility of the Mg acceptor and the higher activation energy of the holes, heat is particularly easy in the lifetime of high-brightness LEDs in the p-type region. Fatal problem with heat dissipation. Generally speaking, whether the LED lamp works stably and with good quality is very important for the heat dissipation of the lamp body itself. At present, the heat dissipation of high-brightness LED lamps on the market often uses natural heat dissipation, and the effect is not ideal. The heat dissipation path of LED devices is mainly heat conduction and convection. The extremely low thermal conductivity of the Sapphire substrate material increases the thermal resistance of the device, produces a serious self-heating effect, and has a devastating effect on the performance and reliability of the device. The effect of heat on high-brightness LEDs. The heat is concentrated in a chip with a small size, and the temperature of the chip rises, causing non-uniform distribution of thermal stress, the chip’s luminous efficiency, and the efficiency of the phosphor lasing. When the temperature exceeds a certain value, Device failure rate increases exponentially.

The relationship between chip size and heat dissipation

The most direct way to increase the brightness of power LEDs is to increase the input power, and to prevent saturation of the active layer, the size of the pn junction must be increased accordingly; increasing the input power will necessarily increase the junction temperature, which in turn reduces the quantum efficiency. The increase in the power of a single tube depends on the device’s ability to extract heat from the pn junction. Under the existing chip material, structure, packaging process, constant current density on the chip, and equivalent heat dissipation conditions, the size of the chip is increased separately. The temperature will keep rising. Strengthening the heat dissipation technology of LED lamps, and introducing and radiating infrared radiation heat to fluorescent lamps are important means to improve the service life of lamps. In the consideration of heat dissipation, we separate the heat dissipation of the LED light source lamp beads and the heat dissipation of the power supply without interfering with each other, thereby ensuring the rationality of heat dissipation. Thereby ensuring the brightness of the LED.

The most direct way to increase the brightness of power LEDs is to increase the input power, and to prevent saturation of the active layer, the size of the pn junction must be increased accordingly; increasing the input power will necessarily increase the junction temperature, which in turn reduces the quantum efficiency. The increase in the power of a single tube depends on the device’s ability to extract heat from the pn junction. Under the existing chip material, structure, packaging process, constant current density on the chip, and equivalent heat dissipation conditions, the size of the chip is increased separately. The temperature will keep rising. Strengthening the heat dissipation technology of LED lamps, and introducing and radiating infrared radiation heat to fluorescent lamps are important means to improve the service life of lamps. In the consideration of heat dissipation, we separate the heat dissipation of the LED light source lamp beads and the heat dissipation of the power supply without interfering with each other, thereby ensuring the rationality of heat dissipation. Thereby ensuring the brightness of the LED.

Solution for heat dissipation of LED light bulbs: To solve the heat dissipation of LED light bulbs, it mainly starts from two aspects. Before and after packaging, it can be understood as the heat dissipation of LED chips and LED light bulbs.

1. Cooling method

Aluminum heat sink fins: This is the most common way to dissipate heat. Aluminum heat sink fins are used as part of the case to increase heat dissipation area.

Thermally conductive plastic shell: filled with thermally conductive material during injection molding of the plastic shell to increase the heat and heat dissipation capacity of the plastic shell. Aerohydrodynamic heat dissipation: The aerodynamics uses the shape of the lamp housing to create convective air, which is the lowest cost way to enhance heat dissipation. The fan lamp housing uses a long-life high-efficiency fan to enhance heat dissipation: low cost and good effect. However, it is more troublesome to change the fan, and it is not suitable for outdoor use. This design is relatively rare. Heat pipe heat dissipation technology: The heat pipe uses heat pipe technology to conduct heat from the LED chip to the heat dissipation fins of the housing. This is a common design in large light fixtures such as street lights. Surface radiation heat treatment The surface of the lamp shell is treated with radiation heat dissipation: the simple thing is to apply the radiation heat-dissipating paint, which can take the heat away from the surface of the lamp shell by radiation.

Thermally conductive plastic shell: filled with thermally conductive material during injection molding of the plastic shell to increase the heat and heat dissipation capacity of the plastic shell. Aerohydrodynamic heat dissipation: The aerodynamics uses the shape of the lamp housing to create convective air, which is the lowest cost way to enhance heat dissipation. The fan lamp housing uses a long-life high-efficiency fan to enhance heat dissipation: low cost and good effect. However, it is more troublesome to change the fan, and it is not suitable for outdoor use. This design is relatively rare. Heat pipe heat dissipation technology: The heat pipe uses heat pipe technology to conduct heat from the LED chip to the heat dissipation fins of the housing. This is a common design in large light fixtures such as street lights. Surface radiation heat treatment The surface of the lamp shell is treated with radiation heat dissipation: the simple thing is to apply the radiation heat-dissipating paint, which can take the heat away from the surface of the lamp shell by radiation.

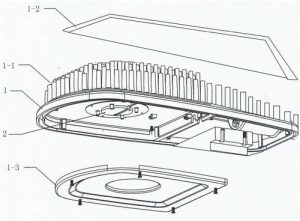

2. LED light source changes brightness

LED light fixtures created by LED light sources are composed of LEDs, heat dissipation structures, drivers, and lenses. Therefore, heat dissipation is also an important part. High-quality LED light sources are used. The chip is placed on the pins. The thermal energy is directly generated by the chip nodes through the silver feet. It comes out in the tropics, which is different from the traditional in-line products and traditional patch products in terms of heat dissipation. The node temperature of the chip will not accumulate, which ensures the good usability of the light source lamp beads and the length of the light source lamp beads. Long life and low light decay. Traditional patch products, although the positive and negative electrodes of the chip can be connected through the gold wire of the chip, and the thermal energy generated by the chip is connected to the silver pin through the gold wire. Both heat and electricity are conducted by money, and the heat accumulation time is long. Will directly affect the life of the LED fluorescent tube.

LED light fixtures created by LED light sources are composed of LEDs, heat dissipation structures, drivers, and lenses. Therefore, heat dissipation is also an important part. High-quality LED light sources are used. The chip is placed on the pins. The thermal energy is directly generated by the chip nodes through the silver feet. It comes out in the tropics, which is different from the traditional in-line products and traditional patch products in terms of heat dissipation. The node temperature of the chip will not accumulate, which ensures the good usability of the light source lamp beads and the length of the light source lamp beads. Long life and low light decay. Traditional patch products, although the positive and negative electrodes of the chip can be connected through the gold wire of the chip, and the thermal energy generated by the chip is connected to the silver pin through the gold wire. Both heat and electricity are conducted by money, and the heat accumulation time is long. Will directly affect the life of the LED fluorescent tube.

3. Production safety guarantees brightness

During the production of LEDs, PC flame retardant plastic tubes are guaranteed to ensure that infrared heat can penetrate the PC tubes. When we design and consider the use of LED lamps, we can give more consideration to their safety and use a fully plastic physical insulation method, even in use. Non-isolated power supply can also ensure the safety of the use of LED lights. This also guarantees an important reason for the brightness stability factor of the LED lamp.

The significance and prospect of LED lighting brightness in use

The era of LED lighting has begun. The market is increasing at a rate of 130% every year. The most important reason is that LED lamps are not environmentally friendly, like energy-saving lamps. They have no tribute, no toxic substances, and long life. (The theoretical life of LEDs is about 100,000 hours. With the advancement of LED lighting technology, the popularization of LED lights will slowly go, and the tide of replacing traditional lighting will inevitably be blocked. For LED lighting, many people will inevitably choose traditional lighting and general installation methods, and LED lighting has Relevant lighting standards, LED lighting should be implemented in accordance with relevant lighting standards in order to make better use of the energy-saving features of LED lighting. Implement the principle of illuminance, which should be high, high, low, and low. The vertical surface illuminance), the directionality and diffusivity of lighting light (including the three-dimensional sense of the product, the gloss and the texture of the product surface, etc.), the brightness of the lighting source, and the color (including color temperature and color rendering) have different requirements.