1 What is an LED?

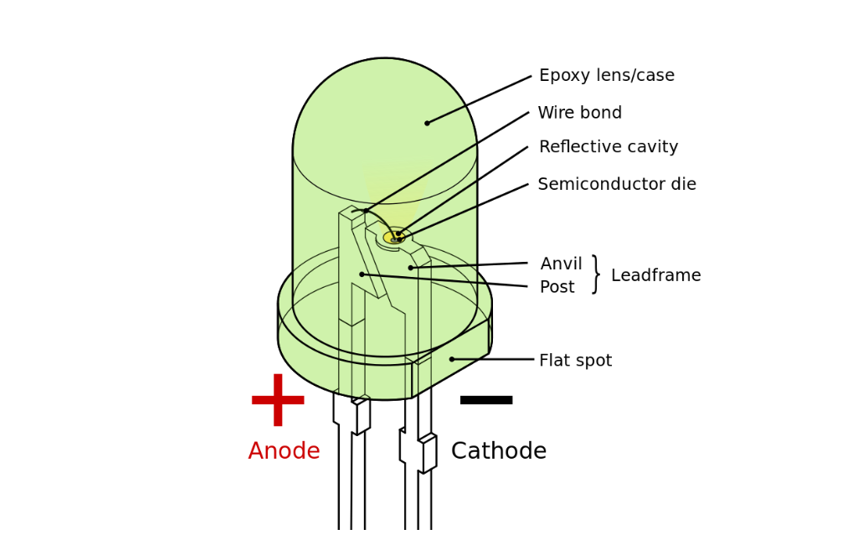

In the simplest terms, a light-emitting diode (LED) is a semiconductor device that emits light when an electric current is passed through it. Light is produced when the particles that carry the current (known as electrons and holes) combine together within the semiconductor material.

Since light is generated within the solid semiconductor material, LEDs are described as solid-state devices. The term solid-state lighting, which also encompasses organic LEDs (OLEDs), distinguishes this lighting technology from other sources that use heated filaments (incandescent and tungsten halogen lamps) or gas discharge (fluorescent lamps).

2 Applications of LED:

LED uses fall into four major categories:

a. Visual signals where light goes more or less directly from the source to the human eye, to convey a message or meaning

b. Illumination where light is reflected from objects to give visual response of these objects

c. Measuring and interacting with processes involving no human vision

d. Narrow band light sensors where LEDs operate in a reverse-bias mode and respond to incident light, instead of emitting light

3 Components of LED:

A LED product contains the following components

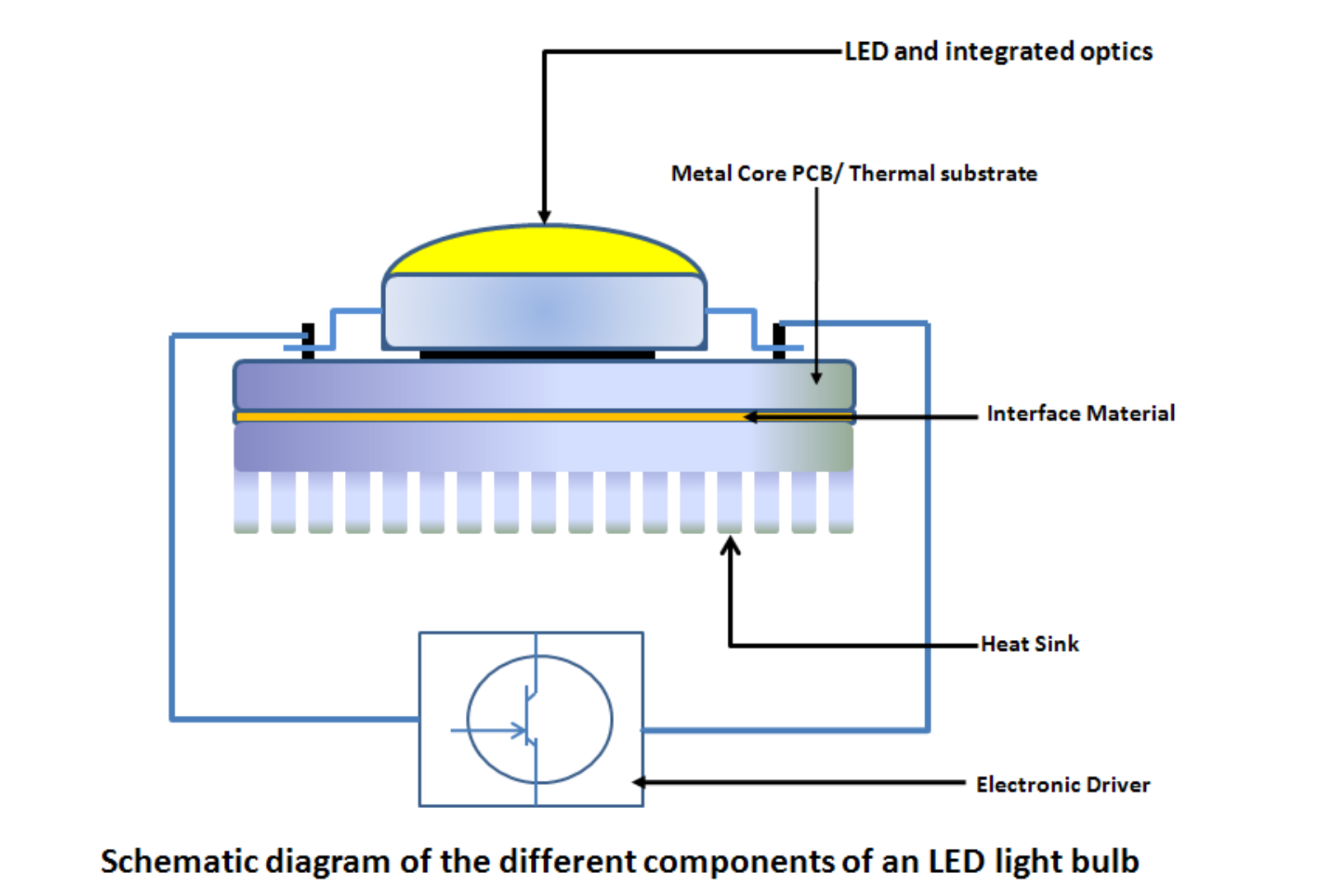

LED cluster: Produces the required amount of light.

Driver Electronics: Changes the household Alternating Current to Direct Current and maintains the right current to power the LED. The electronic ballast converts input voltage to 12V or 24V which is the often occurring input voltage for LED circuit boards. Other Voltages are also possible, even AC driven LEDs. The driver is the brain of the LED bulb.

The two main components of an LED driver are the driver integrated circuit and the driver circuit the driver circuit is also called the electrical control gear.

Instead of using ICs and driver circuits, the required voltage drop can be achieved by using a resistor. But resistors can lead to unacceptable voltage drops and far higher currents than the LED is designed to handle.

Heat sink: The heat generated by the electronic parts and the LED need to be dissipated. Heat sinks that are not designed well or with excess drive currents can result in overheating. This can result in elevated junction temperatures that in turn will compromise both the life and the light produced by the LED.

4 How do LED lights work?

It’s really simple actually, and very cheap to produce, which is why there was so much excitement when LED lights were first invented!

LED lights are composed of two types of semiconducting material (a p-type and an n-type). Both the p-type and n-type materials, also called extringent materials, have been doped (dipped into a substance called a “doping agent”) so as to slightly alter their electrical properties from their pure, unaltered, or “intrinsic” form (i-type).

The p-type and n-type materials are created by introducing the original material to atoms of another element. These new atoms replace some of the previously existing atoms and in so doing, alter the physical and chemical structure. The p-type materials are created using elements (such as boron) that have less valence electrons than the intrinsic material (oftentimes silicon). The n-type materials are created using elements (such as phosphorus) that have more valence electrons that the intrinsic material (oftentimes silicon). The net effect is the creation of a p-n junction with interesting and useful properties for electronic applications. What those properties are exactly depends mostly on the external voltage applied to the circuit (if any) and the direction of current (i.e. which side, the p-type or the n-type, is connected to the positive terminal and which is connected to the negative terminal).

5 The history about LED:

Light-emitting diode is an electric component that emits light when connected to direct current. It works on electroluminescent principle and can emit light in visible specter as well as in infrared and ultraviolet. They have characteristically low energy consumption, small size, longer lifetime and faster switching than incandescence lamps and because of that, they have a wide palette of applicability.

In 1907, British experimenter in Marconi labs Henry Joseph Round noticed for the first time that when a potential of 10volts is applied to carborundum (silicon carbide) crystal, it emits yellowish light. However, first to investigate it and to propose a working theory was Oleg Vladimirovich Losev from Russia. In 1927, Oleg published a paper “Luminous carborundum detector and detection effect and oscillations with crystals“.

For decades no progress was made for different reasons. Rubin Braunstein that worked at Radio Corporation of America, reported in 1955 that some simple diodes emit infrared light when connected to a current. In 1961, Gary Pittman and Bob Biard from Texas Instruments found that that gallium-arsenide diode emits infrared light every time it is connected to current. The same year they received patent for infrared LED. Nick Holonyak Jr., employed in General Electric, developed in 1962 first light-emitting diode that emitted light in the visible part of the frequency range. It was a red LED. In 1972, M. George Craford, who was a graduate student of Holonyak, invented the first yellow LED and a brighter red LED. Thomas P. Pearsall developed high brightness light-emitting diode in 1976, for use with fiber optics in telecommunications. Shuji Nakamura of Nichia Corporation made first blue LED in 1979 but it was too expensive for commercial use until 1994. Light emitting diodes can now be made in one or in more colors.

At first Light-emitting diodes were very expensive, some US$200 per piece. Because of that, they were used as indicators only in highly professional laboratory equipment. Fairchild Semiconductors succeeded in 1970s to reduce cost of individual LED to 5 cents by using planar process in production of semiconductor chips for light emitting diodes. By using innovative methods of packaging and a planar process of chip production, Fairchild made LED into a commercial product with variety of uses.

LED with visible light is used as a replacement for incandescent and neon lights, as elements in seven-segment displays, in large RGB screen displays, in semaphores and other visual signals, in calculators, watches and in flashlights. Infrared LEDs are used in units for remote control in TVs, DVDs and other places that need wireless control.

Advantages of Light emitting diodes are many, but they also have their flaws. Advantages are that they emit more light per watt that incandescent lamps, they are much smaller, their on/off time is much shorter than of the other types of electric light sources (they are quick), their lifetime is much longer and they are much more difficult to damage. Their flaws are high price per lumen, high dependence of the outside temperature and easy overheating if the outside temperature is too high and there is no heat sink. Despite their flaws, LEDs are finding their place in the human use and are here to stay.

6 Advantages of LED Technology:

Light output: In 2002, light output from LEDs was in the region of 20 lumens per watt. Today LED Commercial lighting devices can produce 130+ Lumens per watt. New LED designs can produce as much as 200+ Lumens per watt. This is greater than the light produced by incandescent bulbs (15 lumens per watt) or fluorescent tubes (80-95 Lumens per watt).

Life span: LED lights last anywhere between 30,000 to 100,000 hours. Most commercially available LED lights are rated for a 50,000 to 100,000 hour life span. This means that once installed an LED will last anywhere between 10 to 30 years, depending on the running hours per day. The long life span reduces maintenance expenses and makes these bulbs suitable for difficult to reach locations.

Operating characteristics: LED operate and are not sensitive to low temperature. Additionally, they are not affected by on off cycling. This makes them safer and more efficient in cold environments. They are also better for applications requiring frequent switching of and off lights. The fixtures are not affected by vibrations making them the best choice for places like bridges.

Shock resistant: The energized components of the LED are separated from the outer surface with quality insulation. The electrodes are embedded in the bulb matrix and the driver electronics are encased in its shell. A layer of interface material between the LED and the heat sink ensures that no current can leak to the heat sink.

Vibration resistant: Looking at the LED at the beginning of the post you will see that the electrodes are encased in transparent acrylic. There are no suspended filaments as LEDs are resistant to vibrations. Many avid off road driving fans use LED lights in their SUVs because of this feature alone.