What is LED

LED (Light Emitting Diode), a light-emitting diode, is a solid-state semiconductor device that can convert electrical energy into visible light. It can directly convert electricity into light. The heart of the LED is a semiconductor wafer. One end of the wafer is attached to a bracket, one end is the negative electrode, and the other end is connected to the positive electrode of the power supply.

Structure and lighting principle of led lamp

The core of the light-emitting diode is a wafer composed of a p-type semiconductor and an n-type semiconductor. There is a transition layer between the p-type semiconductor and the n-type semiconductor, which is called a p-n junction. In the PN junction of some semiconductor materials, when the injected minority carriers and the majority carriers are recombined, the excess energy is released in the form of light, thereby directly converting electrical energy into light energy. A reverse voltage is applied to the PN junction, and it is difficult to inject minority carriers, so it does not emit light. This type of diode made by the principle of injection-type electroluminescence is called a light-emitting diode, which is commonly called LED. When it is in the forward working state (that is, plus voltage is applied to both ends), when the current flows from the LED anode to the cathode, the semiconductor crystal emits light of different colors from ultraviolet to infrared, and the intensity of the light is related to the current.

Features of LED light source

1.Voltage: LED uses low voltage power supply, the power supply voltage is between 6-24V, which varies according to different products, so it is a safer power supply than using high voltage power supply, especially suitable for public places.

1.Voltage: LED uses low voltage power supply, the power supply voltage is between 6-24V, which varies according to different products, so it is a safer power supply than using high voltage power supply, especially suitable for public places.

2.Efficiency: 80% less energy consumption than incandescent lamps with the same light efficiency

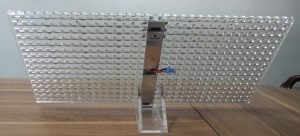

3.Applicability: Very small, each unit LED chip is a 3-5mm square, so it can be prepared into various shapes of devices, and suitable for variable environments

4.Stability: 100,000 hours, the light attenuation is 50% of the initial

5.Response time: The response time of the incandescent lamp is in the millisecond level, and the response time of the LED lamp is in the nanosecond level.

6.Environmental pollution: no harmful metal mercury

7.Color: The color can be changed by changing the current. The light-emitting diodes can be easily chemically modified to adjust the band structure and band gap of the material to achieve red, yellow, green, blue, and orange multicolor light emission. For example, a red LED at a low current can turn orange, yellow, and finally green as the current increases.

8.Price: The price of LED is relatively expensive. Compared with incandescent lamps, the price of several LEDs can be comparable to the price of an incandescent lamp. Usually, each group of signal lamps needs to be composed of 300 ~ 500 diodes.

What causes LED lights to glow when turned off

First of all, let’s start with the principle of LED: The core of LED is a semiconductor light emitting diode chip. One end of the chip is attached to a bracket, one end is a negative electrode, and the other end is connected to the positive electrode of the power supply, so that the entire chip is encapsulated by epoxy resin. A single LED lamp bead can only work at low voltage (about 3V) and low current (about several milliamps), and the light emitted is very weak. Many LED lamp beads need to be connected in series or in parallel; at the same time, a single LED lamp bead is unidirectionally conductive (single-phase continuity of the diode). In order to make full use of the positive and negative half-cycle current of alternating current, this requires an integrated circuit chip. The AC 220V power supply is converted into voltage and current DC power to meet the power supply requirements of the LED lamp bead assembly and enable it to emit light normally. If you turn it off for a short while, then consider the following situations.

First of all, let’s start with the principle of LED: The core of LED is a semiconductor light emitting diode chip. One end of the chip is attached to a bracket, one end is a negative electrode, and the other end is connected to the positive electrode of the power supply, so that the entire chip is encapsulated by epoxy resin. A single LED lamp bead can only work at low voltage (about 3V) and low current (about several milliamps), and the light emitted is very weak. Many LED lamp beads need to be connected in series or in parallel; at the same time, a single LED lamp bead is unidirectionally conductive (single-phase continuity of the diode). In order to make full use of the positive and negative half-cycle current of alternating current, this requires an integrated circuit chip. The AC 220V power supply is converted into voltage and current DC power to meet the power supply requirements of the LED lamp bead assembly and enable it to emit light normally. If you turn it off for a short while, then consider the following situations.

(1) The lighting lamp is generally controlled by a single line. If the switch controls the zero line (phase line through the lamp), it will cause a slight bright after the light is turned off.

(2) Although the lighting lamp controls the phase wire, the lamp control wire is routed together with other active wires, and the wires are not able to withstand the voltage due to quality problems, which will cause the control lamp wire to sense a low voltage and cause the lamp to turn off. There is a slight light.

(3) The switching stroke (gap) of the control lamp is too small or dust accumulates for a long time. In wet weather, the control lamp wire will also sense a low voltage, so that the lamp will still be slightly bright after the lamp is turned off.

Solve the problem that the LED lights up after turning off

This suggests that a small intermediate relay with a 220V voltage attracting coil and two sets of contacts with a contact capacity of 5A should be added to the lighting fixture. The size of this small relay is only the size of a thumb and the price is only a few dollars-one. So it is very economical and easy to retrofit. The specific wiring is as follows; the two wires originally connected to the lamp are respectively connected to the two contacts of the relay suction bowcoil and then connected to the static contact terminals of the two normally open contacts of the relay. After that, connect the two wires of the original lamp to the contacts of the moving contacts of the two normally open contacts of the relay.

This suggests that a small intermediate relay with a 220V voltage attracting coil and two sets of contacts with a contact capacity of 5A should be added to the lighting fixture. The size of this small relay is only the size of a thumb and the price is only a few dollars-one. So it is very economical and easy to retrofit. The specific wiring is as follows; the two wires originally connected to the lamp are respectively connected to the two contacts of the relay suction bowcoil and then connected to the static contact terminals of the two normally open contacts of the relay. After that, connect the two wires of the original lamp to the contacts of the moving contacts of the two normally open contacts of the relay.

Key technologies to improve the quality of LED lamps

1.Heat dissipation problem

The heat dissipation problem exists in all links of LED lamp manufacturing, and the manufacturing process can be optimized by

In order to improve the overall heat dissipation effect, the author divides the process into three stages here, and separately describes the best of the heat dissipation technology.new progress.

1) Chip design phase

If the heat treatment is started from the component side, the heat dissipation planning can be carried out at the chip design stage. The heat dissipation design method for LED epitaxy uses flip-chip for high-power and high-brightness LED components, that is, Flip-Chip form ), Use the flip-chip to conduct heat out of the epitaxy. Another way is to use vertical electrodes (Cree) to make LEDs, which can get more help on heat dissipation. Or use a substrate material with better thermal conductivity, such as SiC (Cree).

If the heat treatment is started from the component side, the heat dissipation planning can be carried out at the chip design stage. The heat dissipation design method for LED epitaxy uses flip-chip for high-power and high-brightness LED components, that is, Flip-Chip form ), Use the flip-chip to conduct heat out of the epitaxy. Another way is to use vertical electrodes (Cree) to make LEDs, which can get more help on heat dissipation. Or use a substrate material with better thermal conductivity, such as SiC (Cree).

2) Packaging stage

LED packaging is the throat of the LED industry. The optimization of heat dissipation in this link plays a significant role in the overall effect. Generally, this can be achieved by selecting packaging materials with better thermal conductivity and changing the packaging process.

- New packaging materials

Diamond-like carbon film (Jiangsu Xinzui), liquid metal (Changzhou Taihe), ceramic substrate (Tongxin Electronics), etc.

- Packaging process

Eutectic soldering method (Cree), COHS (Guanghai Technology), Lumileds Luxeon packaging method, etc.

3) Overall design stage

The overall heat dissipation design of the LED lamp includes a heat dissipation module and an overall structural design. The main types of cooling modules are forced cooling by fans, heat pipes plus fins, and loop heat pipe cooling technologies. In terms of overall mechanism design, each LED application company has its own characteristics. For example, Hangke Optoelectronics uses distributed heat dissipation technology to distribute LED heat sources to independent modules. An accelerated troposphere is formed between the modules. The thermal honeycomb effect is used to accelerate heat dissipation and break the cooling bottleneck of LED street lights. In addition, the company has researched through-hole convection technology, and applied the unique through-convection technology to LED modules, so that convection air is also formed inside the module, which greatly improves the heat dissipation effect, reduces the LED junction temperature, and increases the life of LED lamps.

The overall heat dissipation design of the LED lamp includes a heat dissipation module and an overall structural design. The main types of cooling modules are forced cooling by fans, heat pipes plus fins, and loop heat pipe cooling technologies. In terms of overall mechanism design, each LED application company has its own characteristics. For example, Hangke Optoelectronics uses distributed heat dissipation technology to distribute LED heat sources to independent modules. An accelerated troposphere is formed between the modules. The thermal honeycomb effect is used to accelerate heat dissipation and break the cooling bottleneck of LED street lights. In addition, the company has researched through-hole convection technology, and applied the unique through-convection technology to LED modules, so that convection air is also formed inside the module, which greatly improves the heat dissipation effect, reduces the LED junction temperature, and increases the life of LED lamps.

2.Progress of secondary light distribution technology

At present, the basic optical components used in the LED secondary light distribution design are mainly lenses, reflectors, and refractive plates.

1) lens

The function of the lens is to converge and diverge the light emitted by the light source, and to change the size of the light angle, thereby changing the lighting area and illuminance. In practical use, the beam divergence angle is controlled by changing the distance from the light source to the lens. The distance decreases, the divergence angle increases, and vice versa. However, the use of lenses brings aberrations and light losses.

The function of the lens is to converge and diverge the light emitted by the light source, and to change the size of the light angle, thereby changing the lighting area and illuminance. In practical use, the beam divergence angle is controlled by changing the distance from the light source to the lens. The distance decreases, the divergence angle increases, and vice versa. However, the use of lenses brings aberrations and light losses.

2) mirror

Mirror and lens are different in principle. The lens uses the principle of refraction, while the mirror uses the principle of reflection or total reflection. The shape is usually a rotating quadric surface, including parabolic, ellipsoidal and hyperbolic.

3) Refraction plate

The function of the refracting plate is to change the direction of the light or the angle of the light beam in a specific direction. Generally, the refractive plate includes a toothed plate, a trapezoidal plate, and a cylindrical or spherical plate. The software used in optical design mainly includes Zemax, Lighttools, Asap, and Tracepro. They each have their own characteristics and advantages, which are loved by the majority of optical design engineers.

3.Reliability

The typical failure modes of LED lamps include different levels of failure modes, which involve the LED packaging structure and process. In actual use of LEDs, due to the complex environment and the limitations of the packaging process, the degradation of packaging materials, phosphor degradation, metal electromigration, and thermal stress caused by local high temperature caused chip or silicone layer delamination or gold wire break And so on, thereby affecting the LED light emission and even causing the entire LED to fail. Moreover, the high temperature generated by the LED will cause the chip’s luminous efficiency to decrease, and the light decay will accelerate, and the color shift will have serious consequences. With the improvement of technology and process, such problems will be solved. Especially in the major reshuffle process of the domestic LED industry, the technical level, especially the reliability of the product will become the most important vitality of the enterprise, and then the LED lighting industry will have a new situation.

The fully independent high-efficiency power driver we designed guarantees the reliability of LED street lights from the perspective of system maintenance. This special driving method independently supplies power to each LED module, adopts soft switching technology and PFC technology to achieve high efficiency. And high power factor, three-level isolation technology to achieve high reliability, fully independent design makes a single module fail Affects the entire lamp work, a single module can be hot-swapped. In addition, the company’s non-destructive topology technology makes single-particle LEDs short-circuited or disconnected, which does not affect the normal operation of the module or the entire lamp, nor does it affect the current and voltage distribution of other LED particles, thereby not affecting the life of other particles.

The fully independent high-efficiency power driver we designed guarantees the reliability of LED street lights from the perspective of system maintenance. This special driving method independently supplies power to each LED module, adopts soft switching technology and PFC technology to achieve high efficiency. And high power factor, three-level isolation technology to achieve high reliability, fully independent design makes a single module fail Affects the entire lamp work, a single module can be hot-swapped. In addition, the company’s non-destructive topology technology makes single-particle LEDs short-circuited or disconnected, which does not affect the normal operation of the module or the entire lamp, nor does it affect the current and voltage distribution of other LED particles, thereby not affecting the life of other particles.

LED Lighting Industry Development Outlook

In recent years, the development of the LED lighting industry has achieved rapid development. With the rising awareness of energy conservation among the global public, and the relatively high electricity prices, it has led to the continuous introduction of LED lighting in construction and commercial applications, while Japan, North America, Europe, and mainland China have become the main application markets. LED lamps have energy saving, environmental protection, Features such as long life, high light efficiency, and the key to success are diversity, emphasis on design and fashion, and functionality, which have been welcomed by the market. With the development of the LED lighting industry, LED lighting products have become a new generation of lighting trends. , Intelligent control stage of LED lamps.

In recent years, the development of the LED lighting industry has achieved rapid development. With the rising awareness of energy conservation among the global public, and the relatively high electricity prices, it has led to the continuous introduction of LED lighting in construction and commercial applications, while Japan, North America, Europe, and mainland China have become the main application markets. LED lamps have energy saving, environmental protection, Features such as long life, high light efficiency, and the key to success are diversity, emphasis on design and fashion, and functionality, which have been welcomed by the market. With the development of the LED lighting industry, LED lighting products have become a new generation of lighting trends. , Intelligent control stage of LED lamps.

With the development of new technologies such as networking, LED, as a semiconductor industry, will also catch up with this high-speed train to show its high controllability. From homes to office buildings, from roads to tunnels, from cars to walking, from auxiliary lighting to main lighting, LED lighting systems with intelligent control will bring higher levels of service to humanity. The LED lamp industry will also go from making products to designing products to providing overall solutions. However, the strong heat and constant flashing frequency emitted by traditional lamps and lanterns have certain harm to the physical and mental health of citizens. However, the new LED lighting tool directly converts the current into a direct current.

The light color is soft, the light intensity is uniform, does not produce flicker and emit a lot of heat, and does not generate ultraviolet rays. Therefore, it does not attract many mosquitoes like ordinary lighting, ensuring that The cleanness and tidyness of the city has further ensured the healthy development of citizens’ physical and mental health, and has promoted the construction of a harmonious and green livable city.