Clean Lighting Design and Wiring

In order to do a good job in the lighting design of a clean room with high cleanliness level, firstly introduce the cleanliness level of the clean room and the airflow pattern of clean air.

Cleanliness of clean workshop:

The national standard GB50073-2013 “Code for Design of Clean Workshops” is equivalent to the relevant provisions of the international standard ISO14644-1, and the air cleanliness grades are divided into 9 grades.

Clean Air Flow Pattern:

The so-called airflow pattern is a reasonable design of the flow pattern and distribution of the air in the clean room. Consideration should be given to avoiding or reducing eddy currents, which is conducive to the rapid and effective removal of pollutants, minimizes and reduces the spread of dust and bacteria emitted by indoor pollution sources, and maintains the air cleanliness level required by the indoor production environment.

For air cleanliness grades 1 to 4, vertical unidirectional flow should be used.

When the air cleanliness level is required to be level 5, vertical unidirectional flow or horizontal unidirectional flow should be used.

For grades 6 to 9, non-unidirectional flow should be used.

Accordingly, according to the cleanliness requirements and airflow pattern of the clean room, we will carry out the lighting design.

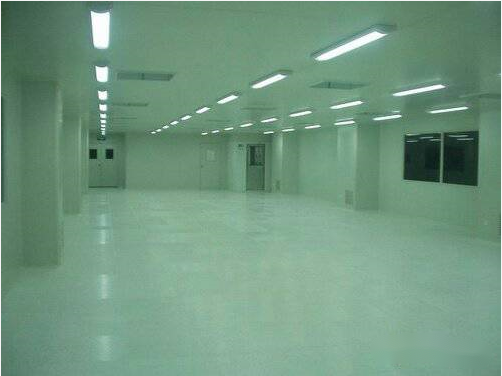

Non-Single Flow Cleanrooms:

For non-unidirectional flow clean rooms, it is best to use ceiling-type thin LED flat lamps, or box-type ceiling fluorescent lamps. Avoid the use of streamlined design lamps produced by turbulent eddy currents, which can effectively prevent dust accumulation.

Horizontal one-way flow clean room:

For the horizontal one-way flow clean room, the supply and return air outlets are installed on the side wall and ceiling, which is convenient for the arrangement of lamps. Ceiling-mounted thin LED flat luminaires are available. If traditional fluorescent lamps are used, since the lamps are thick, they should be recessed to minimize the impact on airflow.

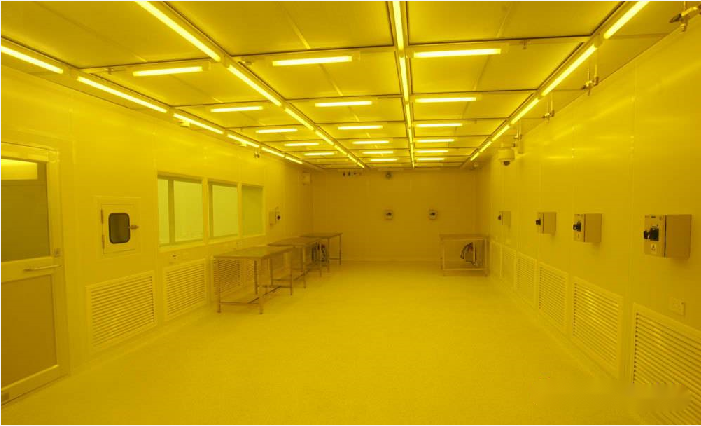

Vertical one-way flow clean room:

For the vertical one-way flow clean room, since the ceiling is arranged with a large number of air outlets and the installation area is small, teardrop fluorescent lamps are often used. More advanced teardrop-type LED lamps can also be used, and the effect is better.

The arrangement of lamps and lanterns is best to use continuous light strip type or intermittent light strip type, and arrange them in a unified manner with fire alarm detectors, air conditioning vents, etc. When installing, pay attention to the method of using sealant and lining to achieve a sealed installation, maintain the pressure difference in the clean room, and avoid pollution.

Taking into account the light and dark adaptation of the production workshop, the illuminance of the aisles and lounges of the clean workshop should not be too different from the illuminance level of the working space. Generally, a difference of 1~2 grades is suitable, but the minimum cannot be lower than 100 lx.

In addition to setting general lighting, local lighting should also be set as required. However, the proportion of local lighting in the mixed lighting illuminance should not be too large to avoid a strong contrast between light and dark.

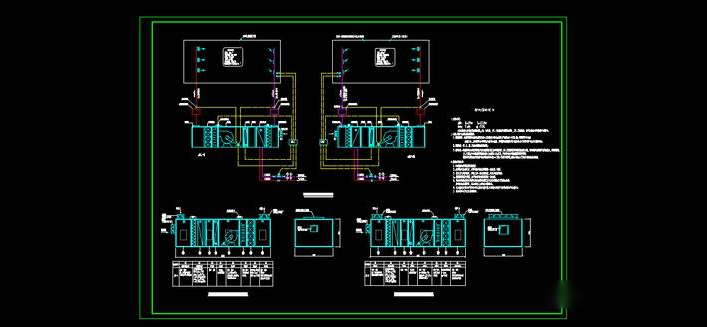

The lighting wiring of the clean workshop should follow the principle of concealment like all kinds of electrical circuits and professional pipes.

The airflow pattern of the clean room is different, and the building structure is also different, but the lighting fixtures are generally installed on the ceiling. Lighting wiring is often in the upper technical interlayer, and the lighting distribution box is located in the center of the technical interlayer, so that it is easy to approach the load center, and the horizontal wiring is short, which is convenient for concealment.

Energy-saving Design of Lighting in Clean Workshop

The lighting requirements of clean workshops are higher than that of general workshops. The indoor ceiling is relatively short, and the energy consumption of lighting is large. In the design, the power density must meet the requirements of the energy saving specification. Specific lighting energy-saving measures include:

1. Select high-efficiency light source

Traditional clean workshop lighting is generally fluorescent tubes, with low luminous efficiency and high power. At present, high-efficiency tri-color lamps can be selected, and high-efficiency electronic ballasts can be configured. As solid-state lighting technology continues to mature, high-efficiency LED light sources should now be preferred.

2. Select a reasonable illumination standard

Different production processes and operations require different illumination standards. Choosing a reasonable illuminance requires not only familiarity with process requirements, but also with lighting products. Many designers are not familiar with the actual luminous efficacy of lamps and lanterns, and they should avoid raising the illuminance standard without authorization and reducing the maintenance factor in order to ensure the illuminance.

3. Choose the right lighting method

The process of clean space is complex, and there are often different levels of lighting needs. In order to effectively reduce energy consumption, the designer should fully communicate with the owner to clarify the process flow and operation requirements in different sections. Places with high contrast requirements use mixed lighting methods, providing basic illuminance through overall lighting, and ensuring sufficient illuminance through additional local lighting.

4. Choose the intelligent control method

The lighting design of the clean space should consider the switch and the control method at the same time. It is a more traditional method to control the lighting by partition and appropriately increase the lighting switch.

With the advancement of technology, the use of time control according to the operating period, the use of light control according to the lighting conditions, the use of infrared sensing according to the flow of people, and even the use of intelligent control methods based on Internet of Things technology are all optional control methods.

Emergency Lighting for Clean Workshops

Function of emergency lighting

The clean workshop is a relatively closed body, and the indoor personnel flow route is complicated. In order to facilitate people to scatter away from the accident scene in the shortest time in the event of an accident and ensure life safety, personnel evacuation indicator lighting should be set up.

The national code stipulates that the evacuation indication signs should be placed on the top of the peace gate or on the wall at the evacuation aisle and its corner which is less than 1 meter above the ground. The distance between the signs on the walkway should not be greater than 20 m. The standard value of the illuminance of evacuation lighting on the channel should not be lower than 0.51x.

However, according to the particularity of the clean workshop, it is recommended to set up evacuation passage lighting to increase the illuminance to 5 lx. Since the clean workshop is generally a 24-hour three-shift work system, the evacuation lighting should be a constant light.

A dedicated fire exit is a dedicated entrance for firefighters to enter a building for the purpose of putting out a fire. The “Code for Design of Clean Workshop” stipulates that red emergency lighting should be installed at the special fire exit, but it is often ignored in practical projects. Attention should be paid to both plan review and construction.

Principles of emergency lighting

Emergency backup lighting should be set up in the clean workshop. Emergency backup lighting is lighting used to ensure that normal activities can continue when normal lighting fails. It can be powered by its own generator, or it can be connected to a different transformer from the power supply trunk line of normal lighting, or separated from the power supply trunk line of normal lighting from the low-voltage panel (or busbar) of the substation.

The spare lighting in the clean room should be evenly arranged in proportion, and its illuminance should not be lower than 10% of the general lighting. The lamps and lanterns can be selected with the same model as the general lighting lamps in the clean room, and lamps with batteries inside. It works as normal lighting at ordinary times, and automatically switches to emergency lighting when the power is cut off. This method is independent in function, simple in wiring, flexible in application, and less limited by external power supply.

Another method that is currently very popular is the centralized power type emergency lighting. Distributed emergency lighting fixtures (without batteries) are powered by a centralized battery power supply device. Under normal conditions, the power supply is supplied by the city. When the city power fails, it will automatically switch to the emergency power supply. When the mains power supply is restored, the power supply device will automatically switch to the mains power supply.