Maintenance Elements of LED Lights

There are many kinds of LED lamps. With more and more applications in the field of urban road lighting, its maintenance is a problem we have to face.

The LED light source has always been high hopes for its green energy saving, dimmable, low maintenance rate and other characteristics. However, due to the limitations of high-power LED products in terms of light efficiency, color temperature, heat dissipation, and penetration, they have not been widely used in the field of road lighting. In recent years, with the advancement of high-power LED lighting technology, more and more LED street lights have been accepted and used by us.

Although the damage rate of LED light sources is very low, with the accumulation of time and the continuous increase in the number of LED street lights, the maintenance of LED street lights is a problem we have to consider.

The LED light source is mainly composed of two core components, an LED drive power supply and an LED light-emitting diode. Compared with standard components such as bulbs, triggers, and rectifiers in traditional sodium light sources, LED light sources do not have uniform standard components for their light-emitting modules and driving power sources due to their different types and combinations of light-emitting diode chips.

At present, the common LED light-emitting modules and driving power supplies mainly fall into the following categories.

Lighting Module

- COB integration

This type of light-emitting module has a high degree of integration, and the COB integrated module can only be replaced as a whole when it is damaged. It is difficult to replace, and accessories can only be purchased from the original manufacturer.

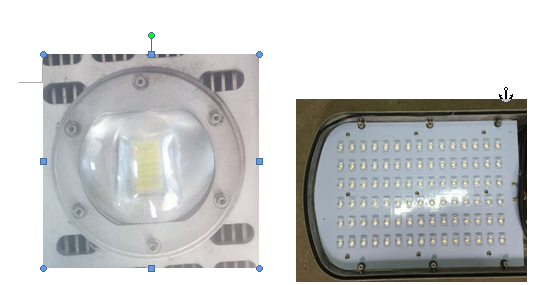

- Circuit board integrated LED dot matrix

This type of light-emitting module is obtained by directly soldering the LED dot matrix on a non-standard circuit board. When it is damaged, the LED light-emitting board can only be replaced as a whole, which is easier to operate. But because it is a non-standard product, accessories can only be purchased from the original manufacturer.

- LED light emitting module

This type of light source module is a standard size, fixed power configuration. When it is damaged, it can be directly replaced with a module of corresponding size and power. It is easy to maintain and operate, and because it is a standardized product, it is also relatively easy to purchase.

Drive Power

- A constant current source

At present, there are many types of constant current sources on the market, and their output current and output power values are different. If it needs to be replaced when it is damaged, the output current of the selected drive power must be equal to that of the replaced drive power, and the output power must be greater than or equal to the value before replacement.

- Constant voltage source

At present, there are many types of constant voltage sources on the market, and their output voltage and output power values are different. If it needs to be replaced when it is damaged, the output voltage of the selected drive power must be equal to that of the replaced drive power and the output power must be greater than or equal to the value before replacement.

- Adjustable constant current source

At present, the commonly used dimming methods on the market include PWM wave, DALI and so on. The driving power must match the type and combination of LED chips.

Continuing the idea of directly replacing bulbs, ballasts and triggers in the maintenance process of traditional sodium lamps, can we finally maintain the same convenient maintenance as traditional sodium light sources in the maintenance of LED lamps?

Modular Design of Drive Power Supply

LED lighting has the characteristics of energy saving, environmental protection, long service life, and wide application. It is an important part of the energy saving and environmental protection industry. With the continuous breakthrough of technology, the increasing appearance of energy-saving effects and the vigorous promotion of energy-saving and environmental protection industries in various countries, indoor LED lighting has replaced incandescent lamps and fluorescent lamps in thousands of households.

Outdoors, street lighting consumes huge amounts of electricity. Driven by the current concept of energy saving and environmental protection, LEDs with high efficiency, energy saving, long service life and high color rendering index have become a new generation of energy-saving light sources in various countries around the world. However, because LED street lights work in harsh outdoor environments, their driving power supplies have high performance and reliability requirements.

1. Analysis of current status of LED street lamp driving power supply life

As a power supply for LED lighting fixtures, the LED drive power supply can convert the external primary electrical energy into the secondary electrical energy required by the LED. The driver is the core component of LED lighting fixtures, and its quality has an important impact on the reliability of LED lighting fixtures. Its stability is also a key factor in the lifespan of LED lighting fixtures.

Through tracking and testing of high-power LED street lights, some LED lights have failed one after another. Through the analysis of the failure, we found that the LED drive power supply damage accounted for as high as 90%. Although the theoretical service life of LED street lamps is as long as 50,000 hours (13.7 years), the service life of its driving circuit is relatively short, about 12,000 hours (3 years). Drive power has become a shortcoming restricting the service life of LED street lights.

In addition, due to the requirements of working conditions such as waterproof and dustproof, LED street lamp driving power is generally encapsulated inside the product. This brings inconvenience to the maintenance of LED street lights, and the cost of replacing the driving power supply is relatively high. Therefore, increasing the service life of the LED street lamp driving power supply, reducing its maintenance cost, and improving the convenience of maintenance will greatly enhance the actual service life and value of the LED street lamp.

2. Solutions (1)

The input power of the LED driving power supply includes alternating current and direct current. The output power is generally a constant current that can change the voltage with the change in the forward voltage of the LED. Therefore, the electronic components required in the driving power supply generally include capacitors, resistors, inductors, and so on.

At present, it is very clear in the industry that if there is an electrolytic capacitor in the LED drive power circuit, its life depends mainly on the electrolytic capacitor. There is a generally accepted approximate calculation rule for the service life of electrolytic capacitors: that is, for every 10 degrees drop in temperature, its service life doubles. For example, an electrolytic capacitor with a nominal life of 2000 hours at 105°C has a lifespan of approximately 32000 hours at 65°C.

The LED street lamp workplace is outdoor. In today’s global warming environment, the ground temperature in summer in most areas has exceeded 70 degrees Celsius. Under such conditions, the average life span of electrolytic capacitors is less than 15,000 hours.

3. Solutions (2)

At present, the electrolytic capacitors in the driving power supply of high-power LED street lamp lighting are soldered on the circuit board, and the entire electrical part is encapsulated inside. When the electrolytic capacitor is damaged and other electrical components are intact, the entire drive power supply will be replaced. This forms a great waste.

As long as the junction temperature and heat dissipation of the LED lamp chip meet the requirements, the life of the LED lamp bead will be nearly 50,000 hours. However, almost all the driving power supplies of LED street lights are damaged early. At present, the warranty period of the driving power supply of LED street lights is generally three years. If calculated on the basis of 12 hours a day and 365 days a year, it only used less than 14,000 hours. The five-year warranty only has nearly 22,000 hours. This is very different from the 50,000-hour service life of LED chip lights.

Although now through intelligent control, the lifespan has been relatively prolonged due to the time-controlled energy-saving reduction of power, but compared with LED lamp beads, its lifespan is still shorter.

4. Solutions (3)

In order to save resources and improve the utilization rate and overall life of the drive power supply, a modular design method can be adopted. The electrolytic easily damaged electrical components are regarded as an accessory separated from the circuit board and not directly installed on the circuit board.

Utilize a shell to encapsulate all relevant vulnerable components into a modular electrical connector, and connect them to each electrolytic capacitor seat in the circuit board with a circuit board or circuit through various connector groups as required. When the electrolytic capacitor reaches the end of its service life, only the module connector needs to be replaced, and the drive power supply can be used again.

During the normal service life of the LED chip, the module connector only needs to be replaced twice under normal circumstances. This can make the overall service life of 50,000 hours of LED street lights a reality. Moreover, the modular connector can be connected to the circuit board through related lines. Through the waterproof, dust-proof and sun-proof design, the installation place can be selected more widely. Subsequent replacement can be carried out easily, without high-altitude operations, and it is as convenient as replacing lights in ordinary households.