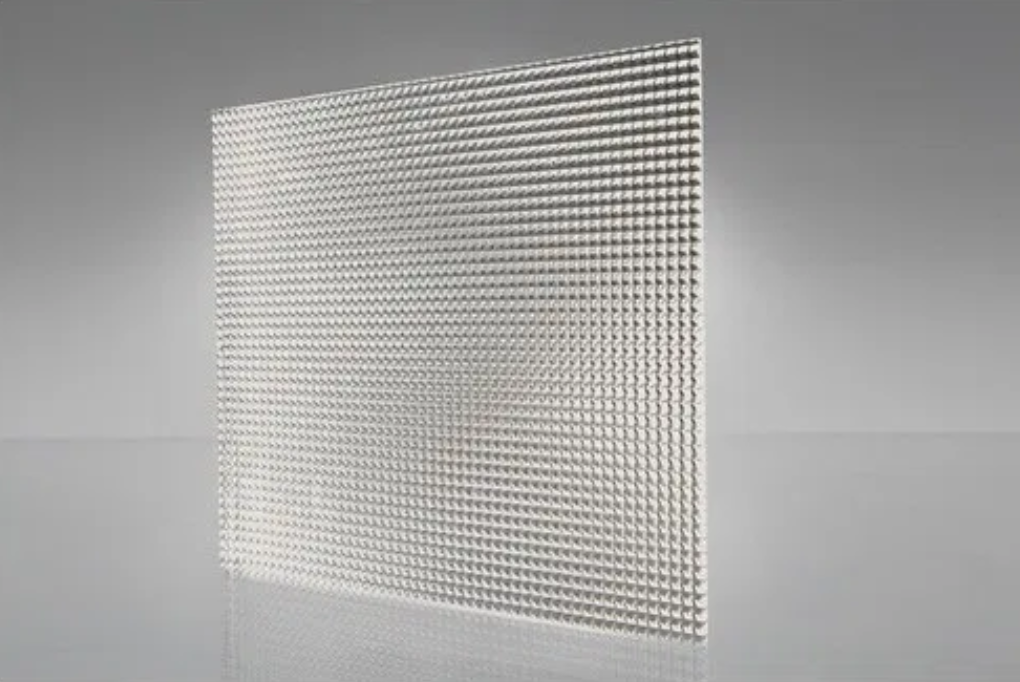

The lighting industry has long been dependant on glass and transparent plastics like acrylic resins for optics design to serve both functional and aesthetic purposes. However, with the advent of LED lighting technology, the necessity for a higher degree of light diffusion has required the development of suitable plastic solutions that do a much better job.

There are various kinds of plastic materials, and some are widely used for LED lighting fixtures, such as PC, PMMA, PS, etc. 90% of Tachyonlight’s lights lense are PC and 10% of PMMA, do you know what’s the difference between them? Let’s have a look here.

What is lens?

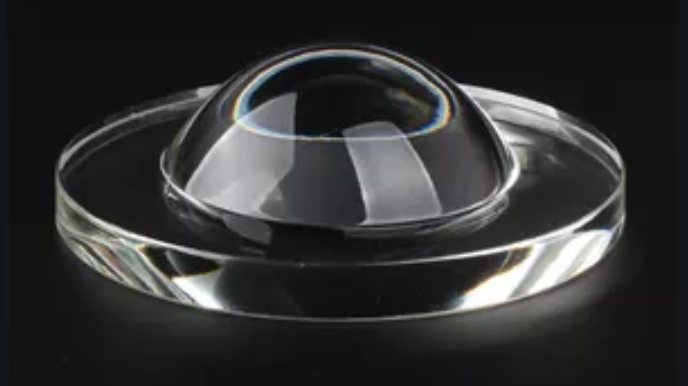

LED lenses come in various shapes and sizes, for example round, square and hexagonal. Common lens materials include plastic and silicone. Therefore some are rigid and some are flexible.

Lenses are designed for use with single or multiple LEDs. This includes LED modules or strips.

They sit over the LEDs to create the desired lighting effect. Various properties of LED lenses enable precise control over the beams of light. LED lenses can also offer a nice aesthetic appearance by masking the LED components within.

What is PMMA(Acrylic)?

Acrylic is a transparent plastic material with outstanding strength, stiffness, and optical clarity. Acrylic sheet is easy to fabricate, bonds well with adhesives and solvents, and is easy to thermoform.

It has superior weathering properties compared to many other transparent plastics. Acrylic sheet exhibits glass-like qualities — clarity, brilliance, and transparency — but at half the weight and many times the impact resistance of glass. From durable signs and skylights to eye-catching retail store fixtures, displays, and shelves, acrylic plastics provide outstanding versatility, durability, and aesthetic qualities.

In conclusion, PMMA / Acrylic offers great performance. It is easy to fabricate and thermoform

What is PC(Polycarbonate)?

Polycarbonate is a tough, transparent plastic material with outstanding strength, stiffness, and impact resistance. Polycarbonate’s optical clarity makes it ideal for applications such as machine guards, signs, face shields, skylights, POP displays. Polycarbonate is also widely used in architectural glazing for medical facilities, retail and government buildings, and transportation centers at risk from breakage and vandalism.

In conclusion, when it comes to durability and stability, PC is one of the best polymers to rely on, given its high fire-rating and good safety certifications.

PMMA (Acrylic) vs PC (Polycarbonate)

1 PMMA has 17 times the impact resistance of glass, PC has 250 times the impact resistance of glass.

2 PMMA is very rigid whereas PC can be bought in flexible grades. Acrylic cracks more easily than polycarbonate under stress.

3 PMMA has light transmittance of 92 percent and PC has a light transmittance of 88 percent in comparison to glass.

4. PMMA can be polished to restore its clarity, while PC cannot.

5 PC can handle temperatures up to 240 deg F while PMMA can handle temperatures up to 190 deg F.

6 PC typically does not crack when being drilled even if drilled close to the edge with a standard drill bit. PMMA will crack if it is drilled near an edge or with a drill bit not designed for plastic.

7 The edges of PMMA can be polished smooth if necessary; PC cannot be polished.

8 PMMA has a low chemical resistance. PC has a higher chemical resistance than PMMA.

9 PMMA is more likely to chip than PC because it is less impact-resistant. It does not scratch easily, however, and will not yellow over time.

10 PC has low flammability, while PMMA will burn slowly and is not recommended in areas where flames may be present.

11 PC is more expensive than PMMA. It tends to cost about 35% more.

Some simple identification methods:

PC:

The recognition method of the PC board is: high transparency, good impact resistance, generally not burning when burned with fire, flame retardant, and some black thick smoke will be emitted.

PMMA(acrylic):

There are extrusion PMMA board and casting PMMA board, the recognition of the extrusion board is that the transparency is good, the flame is clear when burning, no smoke, there are bubbles, and the filament can be pulled out when extinguishing. The identification of the casting board is: the transparency is higher, when burning with fire, there is no smoke, there are bubbles, squeaking noise, and there is no filament when extinguishing the fire.

The properties of these two materials are different in processing and application. And their cost is also different. PC is a better lens material and also more expensive. If you have any questions about the materials and LED lighting products, welcome to contact us directly.