Overview

The key to modern lighting design is light. As people in the lighting industry, we often say “we are selling light, not fixtures”. We advocate the lighting concept of “focus on the value of light and feel the charm of light”. How to “focus on the value of light” I would like to do some superficial discussions, in order to start a discussion, and discuss the connotation of this sentence with everyone.

Light is necessary for human life, and lighting is a symbol of human civilization. People have used light for hundreds of millions of years.

In today’s highly developed society, lighting has penetrated almost all areas of human activities, whether it is day or night, whether it is natural light or artificial light, everything in the world is changing under the action of light.

In the past, we only had to have “light”, and we never paid too much attention to it. Nowadays, when energy and products are greatly improved and energy is very tight, people have the conditions to pursue higher quality light. It is not only required to “illuminate”, but also to accurately control the light for different occasions, including its quality and quantity. This is a functional requirement. At the same time, people have more decorative and artistic demands for light.

Light enters the human eye to cause vision is an important way for people to understand the objective world, so that people can see the shapes and colors of everything. Therefore, maintaining a proper lighting environment in daily life is extremely important.

The electromagnetic wave of this wavelength in the visual range is called visible light, but the light wave only occupies a small part of the extremely broad electromagnetic spectrum, and its wavelength range is between 380nm (nanometer) and 780nm.

The wavelength of visible light is different, and the color perceived by the human eye is also different. From 780nm to 380nm, there are seven colors of red, orange, yellow, green, cyan, blue, and purple. Radiation with a wavelength greater than 780nm and radiation less than 380nm can not cause vision. The former is called infrared radiation, such as microwaves and radio waves. The latter is called ultraviolet radiation, such as X-rays and cosmic rays.

The properties of light are described by many parameters, including frequency, wavelength, luminous flux, luminous efficiency, illuminance, brightness, light intensity, light color, color temperature, color rendering, efficiency, glare, beam angle, and light ratio. Here, I want to focus on the following most basic and important lighting indicators: luminous flux, luminous efficiency, illuminance, illuminance uniformity, color temperature, color rendering and glare. The most basic principle for selecting light sources in urban lighting projects is to choose energy-saving products with high light efficiency, color temperature and color rendering that meet the design requirements and long life.

The Indicator of Whether the Light source Is Energy-saving or Not

To measure whether the light source is energy-saving, it is measured by the amount of visible light (luminous flux) emitted by the light source and its luminous efficiency (luminous efficiency). According to the use function of the road, illuminance and uniformity of illuminance are the most basic evaluation indicators of road lighting.

Luminous Flux and Luminous Efficiency

Luminous flux is a basic optical parameter. It is the total energy of visible light emitted by the light source per unit time. It is used to measure the amount of light emitted by the light source. The unit is Lm (lumens). The more the light source emits, the greater the lumens. The luminous flux of a 40W incandescent lamp is about 400Lm, the luminous flux of a 36W fluorescent lamp is about 2500Lm, and the flux of a 400W high-pressure sodium lamp commonly used in road lighting is about 48000Lm.

When lighting designers do lighting design, they can know the luminous efficiency of a light source by referring to the luminous flux and power parameters of the light source. Especially in today’s promotion of energy conservation, the use of high-efficiency light source appliances and lamps has become a general trend. In the above example, the luminous efficiency of the incandescent lamp is 400÷40=10Lm/w, which is very low. The luminous efficiency of the fluorescent lamp is 2500÷36=70Lm/w, and the value is high, indicating its energy saving. The luminous efficiency of the high-pressure sodium lamp is 48000÷400=120Lm/w, which is higher and more energy-saving.

The luminous efficiency of commonly used light sources is as follows (unit: Lm/w)

|

Light Source |

luminous efficiency |

Light Source |

luminous efficiency |

|

Incandescent lamp |

6.9~11 |

Energy saving lamp |

50~65 |

|

Self-ballasted mercury lamp |

10~15 |

metal halide lamp |

80~120 |

|

High-pressure mercury lamp |

47.5~52 |

High-pressure sodium lamp |

84~150 |

|

Tungsten halogen lamp I |

15~25 |

nduction lamp |

70~83 |

In the road lighting industry, by comparing the performance parameters of various light sources and considering the requirements of road lighting, high-pressure sodium lamps have the characteristics of high luminous efficiency, long life, and color rendering that also meets the requirements of general road lighting. They are used as motor vehicle traffic roads. The light source of choice for lighting.

However, incandescent lamps, self-ballasted high-pressure mercury lamps and fluorescent high-pressure mercury lamps of 125W and above will cause energy waste due to low luminous efficiency, and the level of road lighting is also difficult to meet the standard requirements. Therefore, these two light sources should not be used for urban road lighting.

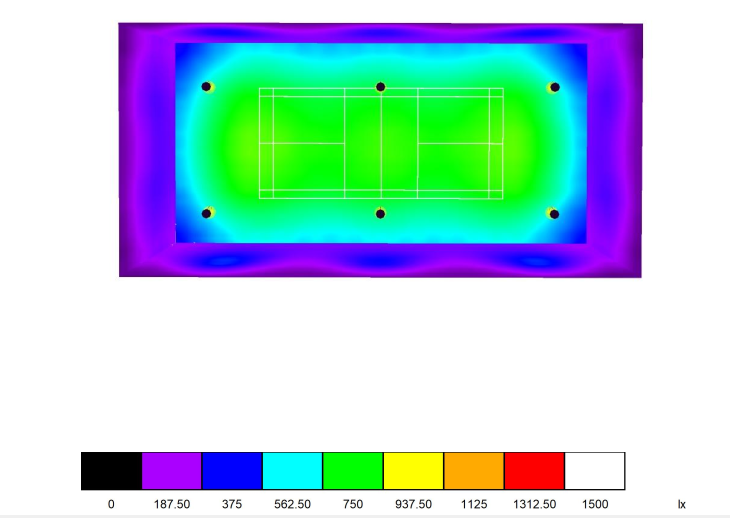

Illuminance

Illuminance refers to the luminous flux received per unit area, which is used to measure the degree of illumination of the illuminated surface, and the unit is lux (Lx). For example, if the luminous flux emitted by a light bulb is 15000Lm, if all the lights fall on 100m2, then the average illuminance is 15000÷100=150Lx, but this is absolutely ideal. In actual application, the efficiency of the lamp, the maintenance factor and the attenuation of the light source must also be considered, and the calculation is very cumbersome. At present, we can do it with the help of professional lighting calculation software.

Common illuminance in daily life is as follows (unit: Lx)

|

Lighting environment |

Illumination (Lx) |

Lighting environment |

Illumination (Lx) |

|

Direct sunlight on a sunny day |

105~2×105 |

Ordinary home environment |

30~100 |

|

In the shadow of a sunny day or overcast |

104~3×104

|

Under the street lights at night |

10~30 |

|

Bright indoor window |

105~3×103 |

Sunny full moon |

0.5 |

|

Bright office |

500~800 |

/ |

/ |

When doing lighting design, first determine the illuminance according to the lighting function requirements of the designed place. IEC50035-2005 “Architectural Lighting Design Standard” stipulates lighting standard values for various places. The international industry standard CJJ45-2006 “Urban Road Lighting Design Standard” specifies the illuminance value of urban road lighting and other indicators in detail.

In the design of urban road lighting engineering, if only to meet the average illuminance of the road surface, it may produce very low illuminance in some areas of the road surface, and the vision will produce a brightness difference, which is often referred to as the “zebra effect”, which will lead to the eyes. The contrast sensitivity decreases, and the driver cannot easily detect the targets and obstacles ahead.

In order to prevent the illuminance difference of each area on the road from being too large and to ensure sufficient recognition rate, the index control of road illuminance uniformity (UE) (the ratio of the minimum illuminance on the road surface to the average illuminance on the road surface) is commonly used. It is beneficial to improve the reliability and visual comfort of the vehicle driver’s target detection.

Quality of lighting

In addition to the necessary lighting calculations for the light environment, it is more necessary to consider the quality of the lighting in the environment. The main factors affecting the lighting quality of the light environment are color temperature, color rendering, and glare.

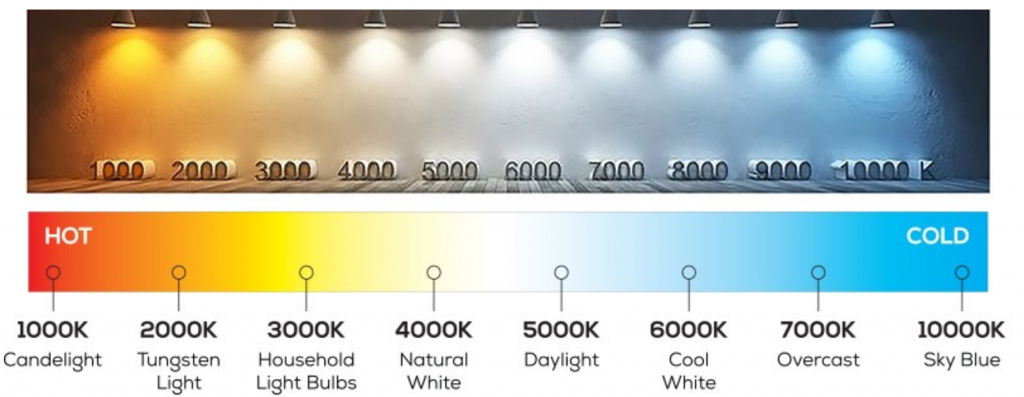

Color temperature

The color of light is calibrated by color temperature. When a black body (such as iron, tungsten, etc.) is heated to a certain temperature, it starts to emit dark red light. As the temperature rises, the color of the light gradually becomes yellowish white. Blue-white until it becomes white light. The temperature of a black body emitting a certain color is called the color temperature of the light of that color, and the unit is K. The color temperature of common light sources in daily life is as follows:

|

Light source

|

Color temperature (K) |

Light source

|

Color temperature (K) |

|

Sun at sunrise and sunset |

3000

|

Incandescent lamp |

2700 |

|

The sun at noon on a sunny day |

6500

|

High pressure sodium lamp |

2200 |

|

Candlelight |

1900 |

Metal halide lamp |

3000~5000 |

The color temperature below 3000K is reddish, yellow, and warm, often with lower illuminance, used to express a warm and elegant atmosphere. The color temperature above 6000K is blue, green and cool. It is often used with higher illuminance to express a refreshing and exciting atmosphere. In the design of urban lighting projects, especially landscape lighting projects, suitable color temperature should be used to accurately express the atmosphere of the space according to different places and illuminated objects.

Generally speaking, there are the following two principles:

(1) Use high color temperature for high illuminance, and low color temperature for low illuminance.

(2) When lighting colorful objects, you can use medium and low color temperature, giving people a soft and intimate feeling. When the lighting color difference is small, and for whiter objects, choose a high color temperature light source close to the natural light color to truly reflect the true color of the illuminated object.

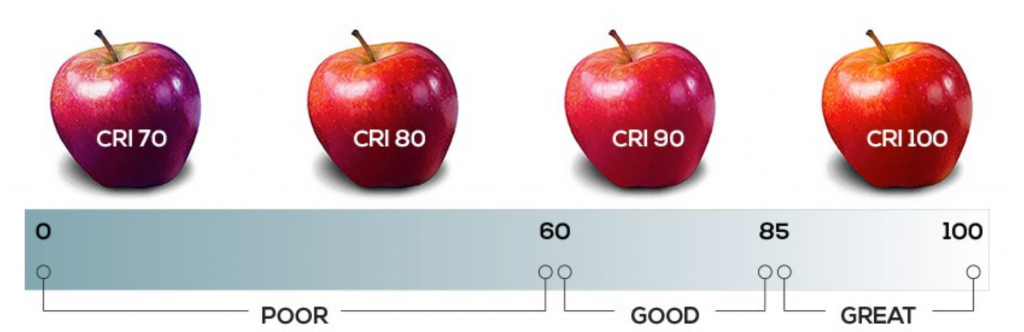

Color rendering

Different light colors have different color rendering capabilities for the same colored object, because the color performance of the object is not only related to the color of the light, but also related to the spectral distribution of the light source. That is, the performance of the light source to show the color of the illuminated object is called the color rendering of the light source.

The International Institute of Illumination (CIE) uses the Color Rendering Index (Ra) to evaluate the color rendering of light sources. The color rendering index of a light source refers to the degree to which the color of the object matches the color of the object under the illumination of the light source to be measured and another black body with a similar color temperature or sunlight reference light source. The color distortion is less, the color rendering index is high, and the color rendering of the light source is good.

In the design of urban road lighting engineering, the requirements for the color rendering index of the main and secondary roads are not very high, and the high pressure sodium lamp is the best choice. However, the color rendering index of commercial street lighting is required to be high, and high color rendering high pressure sodium lamps and metal halide lamps are often used. Because the items that people buy in commercial streets do not have a high color rendering light source, it is often difficult to distinguish the true color of the item.

But the better the color rendering, the worse the light effect. For example, the low-pressure sodium lamps used in some roads in the suburbs radiate yellow light in a narrow range of the spectrum with high luminous efficiency. All objects appear yellow and gray under this light, and the color rendering is particularly poor.

The high-color-rendering high-pressure sodium lamp has a broad yellow spectrum with multiple peaks. The color-rendering performance is much better than that of the low-pressure sodium lamp, but the light efficiency is relatively low. It is widely used in road lighting, outdoor area lighting, square terminal lighting and some places that do not require high color rendering.

Glare

Glare control is a very important evaluation index in road lighting design. There are two types of glare restrictions. One is uncomfortable glare (psychological), which means that when the vehicle is driving, the road lighting reduces the driver’s visual comfort to a certain extent. This is mainly caused by uneven brightness distribution and excessive contrast in the field of view.

The other is disability glare (physiological), which evaluates road lighting fixtures from the perspective of visibility loss. The brightness of the light curtain caused by the scattered light of the lamp in the eyes of the driver reduces the image contrast on the retina, resulting in a decrease in the recognition ability. This is mainly caused by the excessively bright light-emitting surface of the road lighting fixture.

There are many ways to avoid glare. Uncomfortable glare can be eliminated by reducing the surface brightness of the light source or increasing the background brightness of the light source.

To avoid disability glare, when choosing road lighting lamps, choose a lamp that can effectively use the light source to distribute the light output reasonably, shoot the light effectively in the direction that needs to be illuminated, and have a control glare protection angle.

Such as light-cutting luminaires, this type of luminaires strictly limit the light along the road axis, even when the surrounding environment is dark, it will not feel glare. Generally used in important road sections such as expressways and urban arterial roads.

On the one hand, the half-cut illuminator appropriately restricts the light along the axial direction of the road, and on the other hand, extends the light as far as possible to the lateral direction, so that the lamp has a reasonable light distribution effect in the shape of a batwing. At present, such lamps are widely used in general road lighting.