Background

With the continuous consumption of the earth’s energy and the lack of resources, the harm of the greenhouse effect to human beings, and the serious pollution of the atmosphere to the earth, the international call for energy conservation and consumption reduction is getting louder and louder. Today, energy saving ranks first, and road lighting accounts for about 30% of the entire lighting electricity consumption, which is closely related to people’s production and life.

Urban and rural roads will be more and more wide. This requires a large number of energy-saving lamps to match. With the acceleration of urbanization in various countries, green, high-efficiency, energy-saving and long-life lamps have gradually entered people’s field of vision. At present, LED lighting technology is becoming more and more mature, and the efficacy of high-power LED light source has reached more than 200lm/W. It is possible to save energy in urban street lighting.

Advantages of 5W Module Power Supply

The 5w module power supply is aimed at the business opportunities of the entire lighting industry.

In order to seize the opportunity, seize more markets and create more benefits, many lighting companies are scrambling to develop various road lighting to meet the needs of users. Even some companies that did not originally produce lighting products have also launched.

However, due to the differences in the level of lighting knowledge, the current semiconductor lighting products are in a chaotic situation. Some enterprise products have also entered a misunderstanding, which has brought a great negative impact on end customers.

Different from traditional lamps, LED has the characteristics of point light source, high brightness and narrow beam output. Therefore, designers of new LED lamps will put forward higher requirements.

The lighting requirement is the surface lighting effect, and the open space beyond the surface is not the way of lighting. Therefore, the distribution range of the light is effectively controlled, so that the light emitted by the light-emitting tube becomes a long strip of light that spreads along the road surface, and at the same time, the generation of glare must be avoided.

At the azimuth angle where the driver looks at the lamp, the light intensity of the lamp in the direction of the 80° and 90° elevation angles shall not exceed 30cd/1000lm and 10cd/1000lm, respectively. And regardless of the size of the luminous flux of the light source, the maximum value of its light intensity in the 90° angle direction shall not exceed 1000cd.

Therefore, if the light exit angle is not strictly controlled, it will produce strong glare. Some high-brightness LED products may even cause certain light radiation hazards to the human body.

Features of LED Light Source

Lighting is a systematic project. To do a good job of semiconductor lamps, we must first clearly understand the lighting standards and requirements, the light distribution principle of conventional lighting, and the difference between the spherical reflector and the reasonable light distribution of point light sources. Give full play to the advantages of the controllability of the beam angle of the LED point light source and the advantages of the long life of the cold light source.

Semiconductor LED light source has its own characteristics in structure and optical characteristics. Therefore, semiconductor lamps should be designed according to these characteristics.

Today, some manufacturers use the traditional lamp shell to replace the semiconductor wick, and it is impossible to make a good lamp by using the transitional conduction method to dissipate heat. The problem is that the external shape of the lamp body should be combined with the heat dissipation of the light-emitting tube, and the heat dissipation depends on the area. The surface area of existing conventional lighting fixtures is far from sufficient. “Joule’s law of heat” is to have good natural air convection.

The working temperature of LED products should basically be controlled below 65℃. The international standard is 80°C. When the LED operating temperature reaches 85°C, the luminous flux will drop by half. The installation of the luminous tube, the scientific and reasonable optical light distribution, and the sealing of the lamp body are very important. At the same time, the designed lamp body structure is also beneficial to mass industrial production.

LED Light-emitting Diode Selection

The heat dissipation of light-emitting diodes is a key problem for semiconductor lamps to solve. Diodes are cold light sources and do not produce scorching high temperatures like gas discharge lamps. However, today’s LED itself also has thermal energy, and its own temperature resistance capability is limited. Therefore, the heat generated by the light-emitting diode must be effectively dissipated into the air. Light-emitting diodes work at a safe temperature, so that semiconductor lamps can truly reflect the advantages of long life.

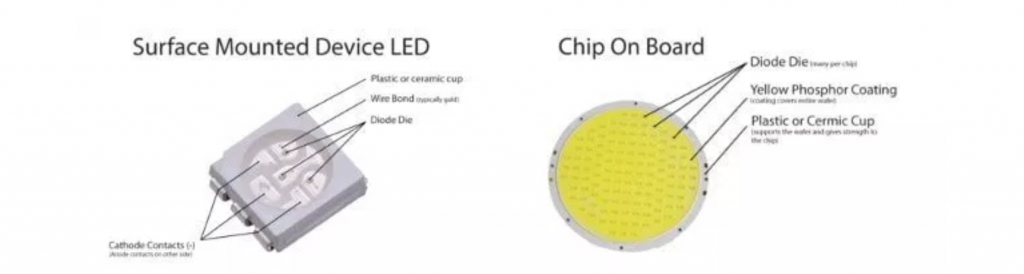

The selection of LED light-emitting diodes is very important. Today, some manufacturers use integrated packages of more than 10W to make lamps in combination. However, it has defects such as difficult optical light distribution, easy generation of glare, and difficulty in overall heat dissipation.

3W ~ 5W modules are also useful. Its light-emitting tube has low light efficiency per watt, and there is also an overall heat dissipation problem. Compared with a single 1W, the price advantage is not obvious under the same luminous flux.

Comprehensive consideration, it is more reasonable to choose high-power 1W LED. Judging from the current technical level of high-power light-emitting tubes, 1W has a relatively high luminous efficiency and has obvious energy-saving advantages for lighting. At present, it is more reasonable to choose 1W as a light source.

LED Light Color Selection

The selection of LED light color is also a factor worthy of attention. In the development of road lighting, there is a comparison of the use of yellow light and white light. Yellow light is once the mainstream high pressure sodium lamp. Because it is economical and energy-saving, and at the same time has excellent fog penetration performance, it has become the mainstream street light choice in the past 50 years.

Even so, yellow light also has its inherent shortcomings, that is, the poor color reproduction ability. People have the feeling that under sodium lighting, the color of anything illuminated is yellowish and distorted.

The pursuit of white light is natural sunlight. Because it has the best color performance. Sunlight is a warm white light. Therefore, if it can achieve white light similar to sunlight, and at the same time take into account the economical and energy-saving advantages of yellow light, it will be an ideal night lighting choice.

In the early days, mainly metal halide lamps emitted white light. Although it has a color performance that is several times higher than that of yellow light, it has not been applied on a large scale due to some insurmountable technical problems such as poor fog permeability and low effective life.

The LED light source can make up for this defect. In terms of color temperature selection of LED light source, about 4500K is more suitable, which meets the lighting requirements in terms of photopic vision and comfort. Moreover, it is feasible in the development of LED light efficiency and cost performance, and is suitable for large-scale promotion of LED lamps.

Classification of LED Lamps

Light cut-off lamps:

The angle between the maximum light intensity direction of the luminaire and the downward vertical axis of the luminaire is between 0° and 65°, and the maximum allowable value of the light intensity in the 90° angle and 80° angle direction is 10cd/1000lm and 30cd/1000lm respectively. And regardless of the size of the luminous flux of the light source, the maximum value of its light intensity in the 90° angle direction shall not exceed 1,000cd.

Semi-cut light fixtures:

The angle between the maximum light intensity direction of the luminaire and the downward vertical axis of the luminaire is between 0° and 75°, and the maximum allowable value of the light intensity in the 90° angle and 80° angle direction is 50cd/1000lm and 100cd/1000lm respectively. And regardless of the size of the luminous flux of the light source, the maximum value of its light intensity in the 90° angle direction shall not exceed 1,000cd.

Because the expressway is long and wide, the traffic flow is large, and the speed of the vehicle is fast, it requires high visual sensitivity. Therefore, the requirements for the power supply of the illumination module, color temperature, brightness uniformity on the road, glare and other indicators are high. In order to compare with 400W high pressure sodium lamps, it is not a wise choice to blindly require high power and high brightness. And today’s LEDs are difficult in terms of light efficiency and heat dissipation costs, and the cost performance needs to be further improved.

Optical Analysis:

Now through Figure 1, it can be preliminarily calculated that the central illuminance of the 198W high-power LED lamp at a height of 12m is: 19870 / 8609.918=28.97Lux. And the central illuminance of 400W sodium lamp at 12m height is about 50Lux. If you consider the color temperature and intermediate visual effect of LED lamps, it can be confirmed that 200W high-power LED lamps can replace 400W sodium lamps. However, if it is purely based on the data measured by the illuminometer, the 200W high-power LED lamp still cannot replace the 400W sodium lamp.