General Introduction

In the field of LED lighting, in order to reflect the energy-saving and long-life characteristics of LED lamps, the correct choice of LED driver IC is very important. Without a good matching of driver ICs, the advantages of LED lighting cannot be reflected. LED lighting lamps have been developed by leaps and bounds in the near future, and are widely recognized as green and environmentally friendly clean light sources. LED light source has long service life, energy saving and power saving, simple and convenient application, and low cost of use, so it will be widely used in home lighting. According to a survey conducted by Osram Optical Semiconductor in 2018, the global annual shipment of household lighting lamp holders is about 50 billion.

The LED driver chip is actually a PWM control chip. After the composition circuit works normally, the voltage obtained by detecting the current of the LED on the back current detection resistor is reflected to the chip, and the internal PWM duty cycle is controlled to adapt to the changes in the characteristics of the LED itself. The resulting current and voltage fluctuations make the current obtained by the LED remain constant.

LED Lighting Driver Circuit

The main technical lighting circuit is also divided into two categories according to the driving mode. The output current of the constant current drive is unchanged, and the output voltage changes with the load resistance; the output voltage of the constant voltage drive is unchanged, and the output current changes with the increase or decrease of the load resistance. Constant current driving is a more ideal way, and the driving circuits used in practice generally have constant voltage and constant current functions.

According to the structure of the LED lighting drive circuit, it is divided into two types: device step-down and PWM switching power supply. Among them, device step-down methods include resistance-capacitance step-down, resistance step-down, and transformer step-down. PWM switching power supply refers to a driving mode that adjusts the width of the on-pulse of the main circuit switching device to maintain a stable output voltage or current. Changing the duty cycle can change the uniform drive current of the LED, thereby changing the luminous intensity of the LED.

LED green lighting promotes the development of driver chips to innovative designs. LED lighting cannot be separated from the driver chip, so a multi-functional LED light source driver IC is required. If an AC power supply below 36v is used for the led lamps, non-isolated power supply can be considered. If you choose 220v and 100v AC power supply, you should consider isolated power supply. Directly use AC 100~220v drive chips. Due to the demanding requirements of the application on the volume, there are still higher technical requirements and greater difficulties, and all countries are working hard to develop them. The massive demand market for LED lamps gives all integrated circuit design companies a chance to succeed again. If they can transform quickly and produce products early, there will be many opportunities to win.

Type of LED Drive Circuit Power Supply

According to the different power supply voltage, the drive circuit can be divided into two categories: DC-powered low-voltage (0.8—1.65V) batteries (such as button batteries), and the drive circuit should adopt a DC/DC boost converter. For other DC power supplies greater than 5V, the drive circuit should use a DC/DC step-down converter; the power supply directly supplied by the AC mains generally needs to undergo AC/DC/DC conversion before it can be used.

Principle and Function of LED Driver

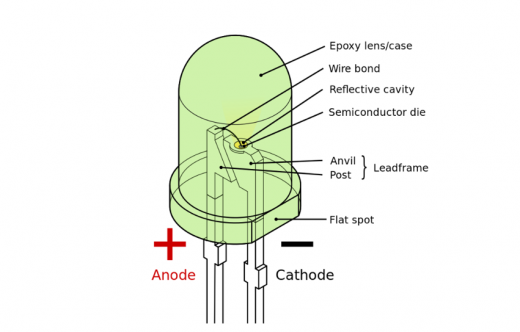

The LED driver refers to the power adjustment electronic components that drive the LED to emit light or the LED module components to work normally. Due to the determination of the conduction characteristics of the LED P-N junction, the voltage and current range of the power supply it can comply with is very narrow. A slight deviation may not be able to light up the LED, or the luminous efficiency may be severely reduced, or the service life may be shortened and the chip may be burned. Current industrial frequency power supplies and common battery power supplies are not suitable for direct supply of LEDs. LED drivers are such electronic components that can send LEDs to work under the optimal voltage or current state.

- Since LED is a characteristic-sensitive semiconductor device and has negative temperature characteristics, the LED drive power supply (also called driver) is the maintenance of its stable working state during the application process.

- The requirements of LED devices for driving power are almost harsh. Unlike ordinary incandescent bulbs, LEDs can directly connect to 220V AC mains. LED is driven by a low voltage, it is necessary to design a complex conversion circuit, LED lights for different purposes, to be equipped with different power adapters. Designing a good power supply must comprehensively consider factors such as efficiency conversion, effective power, constant current accuracy, power supply life, and electromagnetic compatibility. The role of the power supply in the entire lamp is as important as the human heart.

LED Lighting Drive Circuit Typical Chip

When the LED lighting circuit needs to adjust the brightness, its control methods mainly include linear adjustment of the LED current (imitating dimming) and the application of PWM to set the duty cycle and duty cycle (digital dimming). In the face of hundreds of LED driver chips from various electronic companies around the world, we propose: First, try to choose good brand products, and second, comprehensively consider quality and cost based on needs.

The superiority of LED lighting driver IC

- LED high energy-saving: DC drive, ultra-low power consumption (single tube 0.03~1w) electro-optical power conversion is close to 100%, the same lighting effect is more than 80% energy-saving than traditional light sources.

- Long life: LED light source is called long life lamp. Solid cold light source, epoxy resin encapsulation, there is no loose part in the lamp body, there are no shortcomings such as easy burning of filament, heat deposition, fast light decay, etc., and the service life can reach 50,000 to 100,000 hours, which is 10 Times more.

- Environmental protection: LED is a kind of green light source with better environmental protection benefits. There is no ultraviolet and infrared in the spectrum, low heat and no flicker, no radiation, and the waste is recyclable, no pollution, no mercury, cold light source, safe to touch, it is a typical green lighting source.

LED lighting driver IC requirements

- The nominal input voltage range of the driver chip should meet DC 8~40v to cover a wide range of application needs. The pressure resistance is preferably greater than 45v. When the input is AC 12V or 24V, the output voltage of the simple bridge rectifier will fluctuate with the grid voltage, especially when the voltage is high, the output DC voltage will also be high. If the driver IC does not have a wide input voltage range, it will often be broken down when the grid voltage rises, thereby burning the LED light source.

- The nominal output current of the driver chip is required to be greater than 1.2~1.5a. As a led light source for lighting, the nominal working current of a 1w power led light source is 350ma, and the nominal working current of a 3w power led light source is 700ma. High-power LED light sources require more current, so the driver IC selected for LED lighting must have sufficient current output, and the driver IC must also be designed to work in the best working area of 70% to 90% of the full load output. The driver IC with full load output current does not dissipate smoothly in the narrow space of the lamp, which is easy to cause fatigue and early failure of the lamp.

- The output current of the driver chip must be kept constant, so that the LED can emit light stably without flickering. When using the same batch of drive chips under the same conditions, the output current should be as consistent as possible, that is, the discreteness should be small, so that efficiency and order can be ensured when they are produced on a mass automated production line. For the driver chip with a certain discrete output current, it must be selected before leaving the factory or put into the production line. Adjust the resistance value of the current setting resistor on the PCB, so that the constant current driver board for LED lamps produced is compatible with similar LEDs. The luminous brightness of the light source is consistent to maintain the consistency of the final product.