Coefficient Method and Point-by-point Calculation Method

Definition

Lighting calculation is an important part of lighting design. Illuminance calculation is also an important part of lighting function effect calculation. The purpose of illuminance calculation is to determine the power of the lamps and the number of lamps according to the required illuminance value and other known conditions (such as the type and arrangement of luminaires, the reflection conditions and pollution conditions of each surface of the room, etc.).

There are two types of illuminance calculation methods: the coefficient method and the point-by-point calculation method (including the inverse square method, the equal illuminance curve method, the azimuth coefficient method, etc.). The coefficient method is used to calculate the average illuminance and the number of lamps distributed, and the point-by-point calculation method is used to calculate the direct illuminance of a certain point. The characteristics and application scope of these two calculation methods are compared as follows.

using the coefficient method

The illuminance generated by the direct light and the reflected light is considered by the coefficient calculation method. The result of the calculation is the average illuminance on the horizontal plane. Calculate the average illuminance on the indoor horizontal plane, especially suitable for rooms with good reflection conditions. It is generally applicable to the approximate calculation of the number of lamps in production and living rooms.

point-by-point method

Also known as the inverse square method, this method only considers the illuminance generated by direct light, and can calculate the direct illuminance of a point on any surface. Where a direct illuminator is used, the horizontal plane illuminance can be directly obtained.

The iso-illuminance curve method (or the azimuth coefficient method) is generally used to calculate the illuminance of a point on any surface where a line light source is used.

Disadvantage

From the actual use effect, the above two methods have the disadvantages of complicated calculation, many professional conditions, and small scope of application, which are mainly reflected in:

Using the coefficient method:

- For many lighting fixtures with different lighting characteristics, it is not enough to simply divide the hcc in the ceiling space CCR into two forms.

- The effective light reflectance ratio ρcc curve of the existing ceiling cannot meet the colorful interior decoration materials of contemporary buildings, and the classification of the maintenance factor is relatively rough.

- It assumes that the illuminance of all calculation points on the working surface is the same, which cannot meet the calculation of illuminance in some special occasions.

Point-by-point calculation method:

The calculation result is only the minimum illuminance value, which is only suitable for indoor spaces with large area, high clearance, and low reflection of maintenance structures.

In the absence of specialized lighting design software, the above methods are difficult to achieve high accuracy.

With the development of lighting technology, the application of electronic computers and the deepening of architectural decoration, illuminance calculation has been widely concerned and studied by scientists.

From the perspective of research trends, lighting calculation is mainly developed in two aspects. One is to strive for simplicity and speed, and often compile the calculated results under various possible conditions into charts and curves for designers to check. The second is to strive for accuracy. Due to the inaccuracy of various parameters, a 20% to -10% error in the calculation results is allowed. For non-research occasions and general construction design, the real practical method should be simple and easy to calculate and have high accuracy.

Concept and Steps of Unit Capacity Calculation Method

In comparison, a unit capacity method, or a simplified version of the utilization coefficient method, is recommended.

The unit capacity method is suitable for uniform general lighting calculations. It mainly calculates the installation power of lamps required per unit illuminated area, and its formula is as follows:

W=P/S

Among them, P represents the installed power of all lamps (W), and S represents the illuminated area (㎡).

Or directly count the number of fixtures:

N=E*A*φ0*C1*C2/φ,

The unit capacity W is determined by the following various factors: the required illuminance E, the room area A, the luminous flux per LX per unit area φ0, the correction coefficients C1, C2 and the luminous flux (Φ) of the lighting fixtures.

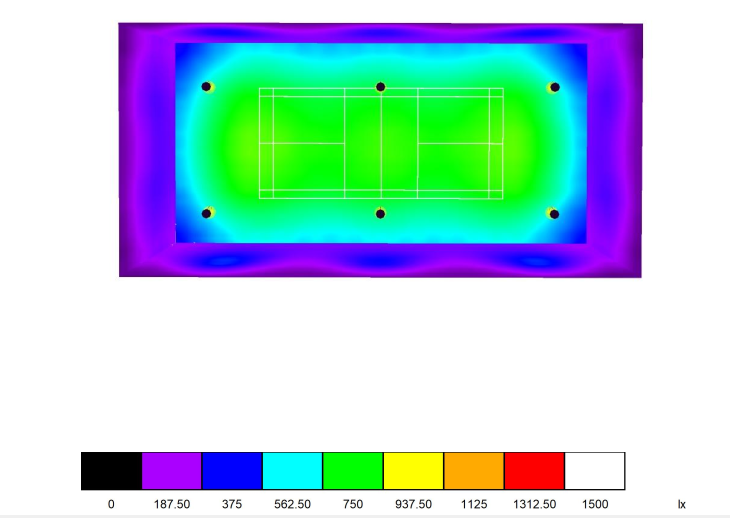

Design Example of Unit Capacity Calculation Method

The dimensions of a factory are: width X length X height = 20m x 50m x 8m. The ceiling reflectance ρC = 70%, the wall reflectance ρW = 50%, and the floor reflectance ρf = 20%. Using 80W LED lights, wide beam angle lighting fixtures. The luminous flux of the light source is 13600lm, and the lamp efficiency is 72.9%. Now the average illuminance of the indoor floor is required to be 100lx. How many lights are arranged in the room?

Step I: Find the chamber shape index RI=W* L/H*(W L), substitute W=20m, L=50m, H=8m, and get RI = 1.78. The lighting fixture is a wide light-distribution LED light, which belongs to the medium illumination type. Distance to height ratio S/h < 1.0. The luminous flux per unit capacity is closest to the value φ0=2.8. According to the efficiency of the lamp and each reflectance, the correction coefficients C1 and C2 are both 1.

Step II: Illumination standard E = 100 lx, workshop area A = 1000㎡.

Step III: The luminous flux φ is 13600lm, and the number of lamps is calculated by substituting into the formula:

N = E*A*φ0*C1*C2/φ=20 <pcs>.

Conclusion

Using the coefficient method, first calculate the room-to-air ratio, headspace ratio and ground-to-air ratio, and then calculate the effective reflection ratio of the ceiling, wall, and floor to determine the utilization coefficient and maintenance coefficient. Although the calculation accuracy of this method is high, the steps are very cumbersome. Unless computer programming is used to assist the calculation, the workload is very large.

The calculation results of the unit capacity method are quite close to the results of the utilization coefficient method, but the calculation steps are much simpler. In actual design, it is often the lamps that are not sure. It is necessary to continuously calculate and adjust the power and position to achieve satisfactory results. This method takes less time to calculate manually, so it is widely used in practice.