Advantage 1. The lamp body is very small

LED lamp is a very small, very fine LED chip encapsulated in transparent epoxy resin, so it is very small, very light, it can save a lot of materials and space in production and application.

Advantage 2 very low energy consumption

The working voltage of the LED lamp is generally only 2~3.6V, and the working current is only 0.02~0.03A. That is to say, it consumes no more than 0.1W, and consumes more than 90% less electricity than incandescent lamps with the same light efficiency, which is more energy-saving The lights are reduced by more than 70%. Therefore, only LED can be called a real energy-saving light source.

Advantage 3, strong and durable

The LED chip is completely encapsulated in epoxy resin. The small epoxy resin particles are extremely difficult to break, and the entire lamp body has no loose parts. The chip inside is extremely difficult to break, and there is little thermal effect and may volatilize and fuse. These characteristics make the LED difficult to damage. Compared with ordinary fluorescent light bulbs, LEDs can be said to be solid, countless times stronger and countless times more durable.

Advantage 4, LED lights have a long service life

Under the right current and voltage, the service life of LED lamps can reach 100,000 hours, that is to say, the service life of the product can reach more than 10 years in theory, which is 3~4 times longer than the service life of other types of lamps.

Advantage 5, safe low voltage

LED lights use low-voltage DC power supply (AC can be rectified into DC), and the power supply voltage is between 6~24V, which varies from product to product. In short, it uses a DC power supply that is safer than a high-voltage power supply, and is especially suitable for homes and public places.

Advantage 6, wide application range

Because of its compactness, each unit LED chip is 3~5mm square or round, so it is more suitable for the preparation of devices with complex modeling process. For example, the manufacture of soft, bendable lamp tubes, lamp strips, and special-shaped lights, currently only LEDs are suitable. Finished LED lights are now widely used in various indoor and outdoor places such as airports, docks, stadiums, gas stations, tunnels, steel plants, oil refineries, ships, highways, and convention centers.

Advantage 7, richer colors

Previously, the colors of lamps on the market were very single. In order to achieve the color purpose, one is to paint or cover the surface of the lamp, and the other is to fill the lamp with inert gas to emit light, so the richness of the color is limited. LED is digitally controlled. The light-emitting chip currently emits a variety of colors, including red, green, and blue. It is precisely with these three colors that can be restored through system control to reproduce the colorfulness of the world.

The luminous color and luminous efficiency of LEDs are related to the materials and manufacturing processes of the LEDs. At present, there are three widely used red, green and blue. Due to the low operating voltage of the LED (only 1.5-3V), it can actively emit light with a certain brightness, and the brightness can be adjusted by voltage (or current), and it is resistant to shock and vibration. LEDs are made of different materials, which can generate photons with different energies, thereby controlling the wavelength of the light emitted by the LED, that is, the spectrum or color.

The material used in the first LED in history is arsenic (As) gallium (Ga), and its forward PN junction voltage drop (VF, which can be understood as lighting or working voltage) is 1.424V, and the emitted light is infrared spectrum. Another commonly used LED material is phosphorous (P) gallium (Ga), which has a forward PN junction voltage drop of 2.261V and emits green light.

Based on these two materials, the early LED industry used the GaAs1-xPx material structure to theoretically produce LEDs of any wavelength in the range from infrared light to green light. The subscript X represents the percentage of phosphorous element substituted for arsenic. Generally, the PN junction voltage drop can determine the wavelength and color of the LED. Among them, GaAs0.6P0.4 red LEDs, GaAs0.35P0.65 orange LEDs, GaAs0.14P0.86 yellow LEDs, etc. are typical. Because the three elements of gallium, arsenic, and phosphorus are used in manufacturing, these LEDs are commonly referred to as three-element light-emitting tubes.

The GaN (gallium nitride) blue LED, GaP green LED and GaAs infrared LED are called two-element light-emitting tubes. At present, the latest process is a four-element LED made of AlGaInN, a four-element material that mixes four elements of aluminum (Al), calcium (Ca), indium (In), and nitrogen (N), which can cover all visible light and part of ultraviolet light. The spectral range of light.

The brightness decay cycle has a lot to do with the material manufacturing process of LED production. Generally, four-element LEDs with slower brightness decay should be used when economic conditions permit. Color matching and white balance: white is a mixture of red, green and blue according to the brightness ratio. When the brightness of green in the light is 69%, the brightness of red is 21%, and the brightness of blue is 10%, the human eye will feel the color after mixing. The result is pure white. However, the chromaticity coordinates of the red, green, and blue LEDs cannot achieve the full color spectrum effect due to the manufacturing process and other reasons, and the brightness of the primary colors including the deviated primary colors is controlled to obtain white light, which is called color matching. Before color matching for a full-color LED screen, in order to achieve the best brightness and the lowest cost, you should try to choose the LED device composition pixels whose luminous intensity of the three primary colors is roughly 3:6:1.

White balance requires the three primary colors to be synthesized under the same gray value and still be pure white. Primary colors, primary colors: Primary colors refer to the basic colors that can be synthesized into various colors. The primary colors in the shade are red, green, and blue. If the primary colors are deviated, the area where colors can be synthesized will decrease, and the triangles in the spectrum table will shrink. From a visual point of view, the colors will not only deviate, but also the richness will decrease.

The red, green, and blue lines emitted by LEDs are roughly divided into purple, pure red, orange-red, orange, orange-yellow, yellow, yellow-green, pure green, emerald green, blue-green, pure blue, blue-violet, etc. according to their different wavelength characteristics. , Yellow-green and blue-violet are much cheaper than pure red, pure green, and pure blue. Of the three primary colors, green is the most important, because green occupies 69% of the brightness of white and is in the center of the horizontal color list. Therefore, in the three-primary color composition method that weighs the purity of the color and the price, in the three-primary color design application, it is usually to achieve the white balance and the maximum desired brightness value by adjusting the LED current.

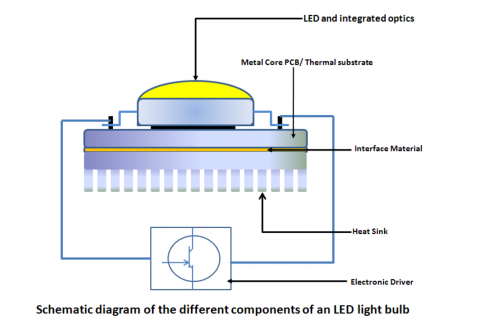

Advantage 8. Less heat dissipation

LED is a more advanced cold light source. It does not radiate a lot of infrared and ultraviolet like incandescent lamps and fluorescent lamps. It is especially suitable for lighting cultural relics, jewelry, high-end cosmetics and other valuables. There is almost no current heating effect like an incandescent lamp, and it will not be affected by thermal expansion and contraction. It will not make the bulb yellow, will not accelerate the aging of the lamp, and will not cause a greenhouse effect on the surrounding environment.

Advantage 9, less environmental pollution

The protective effect of LED on the environment is mainly manifested in three aspects:

One, there is no harm from metallic mercury. LED lamps do not use high-hazard mercury like fluorescent lamps, and there will be no public hazards such as mercury ions and phosphors that may leak during the manufacturing process or after the bulb is broken.

Second, the epoxy resin used to make LEDs is an organic polymer compound, which has good physical and chemical properties after curing, has high bonding strength to chips and metals, is hard and flexible, is stable to salt and alkali and most solvents, and is not easy to damage , Even after damage or aging, it can be recycled and reused without polluting the environment.

Third, the particle layout of LED lamps and displays generally produces light scattered, and light pollution rarely occurs.

Advantage 10, more cost-saving

Compared with incandescent lamps, fluorescent lamps, and LED lamps, the purchase price is higher. However, due to the extremely low energy consumption of LEDs, a large amount of electricity can be saved in the long-term, and the investment in lamp replacement can be saved, so the comprehensive use cost is more cost-effective.